Abstract

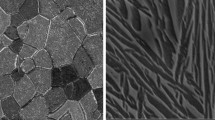

The aim of this study is to examine the effect of solution treatment temperature (STT) on the microstructure, the micromechanical properties, and the kinetic parameters of the β → α phase transformation during continuous cooling of the dual phase titanium alloy Ti-6Al-4V. Increasing the STT from 1050 to 1200 °C delays the formation of the α phase during cooling and increases the value of its activation energy. The microstructural analysis reveals the emergence of αW platelets from protuberances on the αGB/αW interface. The investigation of the morphology of the αW platelets reveals the presence of ledges on their longest side showing a sharp extremity. The micromechanical properties determined by nanoindentation and microhardness tests are almost insensitive to the cooling rate but are strongly affected by the STT; the higher the STT, the lower the overall microhardness of the Ti-6Al-4V alloy. In addition, the STT affects the microhardness and the Young’s modulus of both α and β phases differently; when the STT increases, the microhardness and the Young’s modulus of the α phase decrease, whereas those of the β phase increases.

Similar content being viewed by others

References

M.J. Donachie, Titanium: a Technical Guide, 2nd ed., ASM International, Cleveland, 2000

L.D. Zardiackas, M.J. Kraay, and H.L. Freese, Ed., Titanium, Niobium and Tantalum for Medical and Surgical Applications, ASTM International, West Conshohocken, 2006

S. Banerjee and P. Mukhopadhyay, Phase Transformations Examples from Titanium and Zirconium Alloys, 1st ed., Elsevier, Oxford, 2007

G. Lutjering and J.C. Williams, Titanium, 2nd ed., Springer, Berlin, 2007

C. Leyens and M. Peters, Ed., Titanium and Titanium Alloys: Fundamentals and Applications, Wiley, Hoboken, 2003

C. Cui, B.M. Hu, L. Zhao, and S. Liu, Titanium Alloy Production Technology, Market Prospects and Industry Development, Mater. Des., 2011, 32(3), p 1684–1691. https://doi.org/10.1016/j.matdes.2010.09.011

T. Ahmed and H.J. Rack, Phase Transformations During Cooling in α + β Titanium Alloys, Mater. Sci. Eng., A, 1998, 243(1–2), p 206–211. https://doi.org/10.1016/S0921-5093(97)00802-2

F.J. Gil, M.P. Ginebra, J.M. Manero, and J.A. Planell, Formation of α-Widmanstätten Structure: Effects of Grain Size and Cooling Rate on the Widmanstätten Morphologies and on the Mechanical Properties in Ti6Al4V alloy, J. Alloys Compd., 2001, 329(1–2), p 142–152. https://doi.org/10.1016/S0925-8388(01)01571-7

K. Abbasi, B. Beidokhti, and S.A. Sajjadi, Microstructure and Mechanical Properties of Ti-6Al-4V Welds Using α, Near-α and α + β Filler Alloys, Mater. Sci. Eng., A, 2017, 702, p 272–278. https://doi.org/10.1016/j.msea.2017.07.027

H. Shahmir and T.G. Langdon, An Evaluation of the Hexagonal Close-Packed to Face-Centered Cubic Phase Transformation in a Ti-6Al-4V Alloy During High-Pressure Torsion, Mater. Sci. Eng., A, 2017, 704, p 212–217. https://doi.org/10.1016/j.msea.2017.07.099

Z.X. Zhang, S.J. Qu, A.H. Feng, and J. Shen, Achieving Grain Refinement and Enhanced Mechanical Properties in Ti–6Al–4V Alloy Produced by Multidirectional Isothermal Forging, Mater. Sci. Eng., A, 2017, 692, p 127–138. https://doi.org/10.1016/j.msea.2017.07.099

K. Gu, H. Zhang, B. Zhao, J. Wang, Y. Zhou, and Z. Li, Effect of Cryogenic Treatment and Aging Treatment on the Tensile Properties and Microstructure of Ti-6Al-4V Alloy, Mater. Sci. Eng., A, 2013, 584, p 170–176. https://doi.org/10.1016/j.msea.2013.07.021

H. Matsumoto, H. Yoneda, K. Sato, S. Kurosu, E. Maire, D. Fabregue, T.J. Konno, and A. Chiba, Room-Temperature Ductility of Ti-6Al-4V Alloy with α’ Martensite Microstructure, Mater. Sci. Eng., A, 2011, 528(3), p 1512–1520. https://doi.org/10.1016/j.msea.2010.10.070

C.A. Dubé, H.I. Aaronson, and R.F. Mehl, La Formation de La Ferrite Proeutectoïde Dans Les Aciers Au Carbone, Rev. Métall., 1958, 55(3), p 201–210

H. Beladi, Q. Chao, and G.S. Rohrer, Variant Selection and Intervariant Crystallographic Planes Distribution in Martensite in a Ti-6Al-4V Alloy, Acta Mater., 2014, 80, p 478–489. https://doi.org/10.1016/j.actamat.2014.06.064

W.G. Burgers, On the Process of Transition of the Cubic-Body-Centered Modification into the Hexagonal-Close-Packed Modification of Zirconium, Physica, 1933, 1(7–12), p 561–586

I. Katzarov, S. Malinov, and W. Sha, Finite Element Modeling of the Morphology of β to α Phase Transformation in Ti-6Al-4V Alloy, Metall. Mater. Trans. A, 2002, 33(4), p 1027–1040. https://doi.org/10.1007/s11661-002-0204-4

L.C. Zhang and L.Y. Chen, A Review on Biomedical Titanium Alloys: Recent Progress and Prospect, Adv. Eng. Mater., 2019, 21(4), p 1–29. https://doi.org/10.1002/adem.201801215

R. Filip, K. Kubiak, W. Ziaja, and J. Sieniawski, The Effect of Microstructure on the Mechanical Properties of Two-Phase Titanium Alloys, J. Mater. Process. Technol., 2003, 133(1–2), p 84–89. https://doi.org/10.1016/S0924-0136(02)00248-0

I. Ghamarian, P. Samimi, V. Dixit, and P.C. Collins, A Constitutive Equation Relating Composition and Microstructure to Properties in Ti-6Al-4V: As Derived Using a Novel Integrated Computational Approach, Metall. Mater. Trans. A, 2015, 46(11), p 5021–5037. https://doi.org/10.1007/s11661-015-3072-4

I. Ghamarian, B. Hayes, P. Samimi, B.A. Welk, H.L. Fraser, and P.C. Collins, Developing a Phenomenological Equation to Predict Yield Strength from Composition and Microstructure in β Processed Ti-6Al-4V, Mater. Sci. Eng., A, 2016, 660, p 172–180. https://doi.org/10.1016/j.msea.2016.02.052

J. Cai, F. Li, T. Liu, and B. Chen, Investigation of Mechanical Behavior of Quenched Ti-6Al-4V Alloy by Microindentation, Mater. Charact., 2011, 62(3), p 287–293. https://doi.org/10.1016/j.matchar.2011.01.011

J. Dong, F. Li, and C. Wang, Micromechanical Behavior Study of α Phase with Different Morphologies of Ti-6Al-4V Alloy by Microindentation, Mater. Sci. Eng., A, 2013, 580, p 105–113. https://doi.org/10.1016/j.msea.2013.05.032

E.A. Trofimov, R.Y. Lutfullin, and R.M. Kashaev, Elastic Properties of the Titanium Alloy Ti-6Al-4V, Lett. Mater., 2015, 5(1), p 67–69

A.N. Kolmogorov, On the Statistical Theory of Metal Crystallization, izv. Akad. Nauk. SSSR Ser. Mat., 1937, 3, p 355–360

M. Avrami, Kinetics of Phase Change. I: General Theory, J. Chem. Phys., 1939, 7(12), p 1103–1112. https://doi.org/10.1063/1.1750380

M. Avrami, Kinetics of Phase Change II: Transformation-Time Relations for Random Distribution of Nuclei, J. Chem. Phys., 1940, 8(2), p 212–224

W.A. Johnson and R.F. Mehl, Reaction Kinetics in Processes of Nucleation and Growth, Am Inst Min. Metall. Pet. Eng., 1939, 135, p 416–458

J.W. Cahn, Transformation Kinetics During Continuous Cooling, Acta Metall., 2000, 4(6), p 572–575. https://doi.org/10.1016/0001-6160(56)90158-4

N. Kherrouba, M. Bouabdallah, R. Badji, D. Carron, and M. Amir, Beta to Alpha Transformation Kinetics and Microstructure of Ti-6Al-4V Alloy During Continuous Cooling, Mater. Chem. Phys., 2016, 181, p 462–469. https://doi.org/10.1016/j.matchemphys.2016.06.082

L.C. Zhang and H. Attar, Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review, Adv. Eng. Mater., 2016, 18(4), p 463–475. https://doi.org/10.1002/adem.201500419

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564–1583. https://doi.org/10.1557/JMR.1992.1564

Z. Fan, On the Young’s Moduli of Ti-6Al-4V Alloys, Scr. Metall. Mater., 1993, 29(11), p 1427–1432. https://doi.org/10.1016/0956-716X(93)90331-L

I. Sen and U. Ramamurty, Elastic Modulus of Ti-6Al-4V-XB Alloys with B up to 0.55 Wt%, Scr. Mater., 2010, 62(1), p 37–40. https://doi.org/10.1016/j.scriptamat.2009.09.022

H. Fujii, Continuous Cooling Transformation Characteristics of α + β Titanium Alloys, Nippon Steel Tech. Rep., 1994, 62, p 74–79

Z. Sun, S. Guo, and H. Yang, Nucleation and Growth Mechanism of α-Lamellae of Ti Alloy TA15 Cooling from an α + β Phase Field, Acta Mater., 2013, 61(6), p 2057–2064. https://doi.org/10.1016/j.actamat.2012.12.025

M. Cabibbo, S. Zherebtsov, S. Mironov, and G. Salishchev, Loss of Coherency and Interphase α/β Angular Deviation from the Burgers Orientation Relationship in a Ti–6Al–4V Alloy Compressed at 800 °C, J. Mater. Sci., 2013, 48(3), p 1100–1110

X. Tan, Y. Kok, W.Q. Toh, Y.J. Tan, M. Descoins, D. Mangelinck, S.B. Tor, K.F. Leong, and C.K. Chua, Revealing Martensitic Transformation and α/β Interface Evolution in Electron Beam Melting Three-Dimensional-Printed Ti-6Al-4V, Sci. Rep., 2016, 6, p 26039

S. Zherebtsov, G. Salishchev, and S. Lee Semiatin, Loss of Coherency of the Alpha/Beta Interface Boundary in Titanium Alloys During Deformation, Philos. Mag. Lett., 2010, 90(12), p 903–914. https://doi.org/10.1080/09500839.2010.521526

B. Appolaire, L. Héricher, and E. Aeby-Gautier, Modelling of Phase Transformation Kinetics in Ti Alloys—Isothermal Treatments, Acta Mater., 2005, 53(10), p 3001–3011. https://doi.org/10.1016/j.actamat.2005.03.014

D.A. Porter, K.E. Easterling, and M.Y. Sherif, Phase Transformation in Metals and Alloys, 3rd ed., CRC Press, Boca Raton, 2009

H.I. Aaronson, W.B. Triplett, and G.M. Andes, Phase Transformations in Hypoeutectoid Ti-Cr Alloys, J. Miner. Met. Mater. Soc., 1957, 9(10), p 1227–1235

S. Bein and J. Béchet, Phase Transformation Kinetics and Mechanisms in Titanium Alloys Ti-6.2.4.6, β-CEZ and Ti-10.2.3, J. Phys. IV, 1996, 6, p 99–108. https://doi.org/10.1051/jp4:1996110

S. Malinov, Z. Guo, W. Sha, and A. Wilson, Differential Scanning Calorimetry Study and Computer Modeling of Beta ⇒ Alpha Phase Transformation in a Ti-6Al-4 V Alloy, Metall. Mater. Trans. A, 2001, 32(4), p 879–887. https://doi.org/10.1007/s11661-001-0345-x

A.R. Massih and L.O. Jernkvist, Transformation Kinetics of Zirconium Alloys under Non-Isothermal Conditions, Model. Simul. Mater. Sci. Eng., 2009, 17, p 055002

N.C. Elfer and S.M. Copley, Titanium Science and Technology, G. Lutjering, U. Zwicker, and W. Bunk, Ed., DGM, Oberursel, 1985, p 1789

G.D. Hughes, S.D. Smith, C.S. Pande, H.R. Johnson, and R.W. Armstrong, Hall–Petch Strengthening for the Microhardness of Twelve Nanometer Grain Diameter Electrodeposited Nickel, Scr. Metall., 1986, 20(1), p 93–97. https://doi.org/10.1016/0036-9748(86)90219-X

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kherrouba, N., Carron, D., Bouabdallah, M. et al. Effect of Solution Treatment on the Microstructure, Micromechanical Properties, and Kinetic Parameters of the β → α Phase Transformation during Continuous Cooling of Ti-6Al-4V Titanium Alloy. J. of Materi Eng and Perform 28, 6921–6930 (2019). https://doi.org/10.1007/s11665-019-04404-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04404-5