Abstract

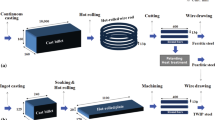

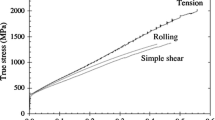

The effects of stress state on the twin structures and kinetics in twinning-induced plasticity (TWIP) steel have been investigated to understand the twinning behaviors in more detail. Twinning behaviors of tension, compression, wire drawing, and caliber rolling were evaluated and compared using the EBSD technique, TEM measurement, and Schmid factor analysis. Twin structures, such as twin thickness, twin variant, twin shape, and twin kinetics were different with stress states. The specimen under compressive stress had wavy-shaped twins, less twin variant, lower twin thickness, and more twin volume fraction in comparison with the specimen under tensile stress. The different structures and kinetics of deformation twin with stress state were highly related to the grain rotation during plastic deformation. Under tensile stress, the grain rotation to <111> orientation, twinning-favored regions by Schmid factor analysis, encouraged the lateral growth of twins, more twin variants, and straight-type twins, while the grain rotation to <110> orientation under compressive stress suppressed the twin growth and twin variant and developed wavy-shaped twins. Drawn wire and caliber-rolled wire had both twin features under tensile and compressive stress states and higher twin volume fraction since complex stress state that combined tension and compression was applied in these processes. The hardness values were strongly related to the twin volume fraction with strain and stress state.

Similar content being viewed by others

References

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier, High Manganese Austenitic Twinning Induced Plasticity Steels: A Review of the Microstructure Properties Relationships, Curr. Opin. Solid State Mater. Sci., 2011, 15, p 141–168

O. Grassel, L. Kruger, G. Frommeyer, and L.W. Meyer, High Strength Fe-Mn-(Al, Si) TRIP/TWIP Steels Development-Properties-Application, Int. J. Plast., 2000, 16, p 1391–1409

B.C. De Cooman, Y. Estrin, and S.K. Kim, Twinning-Induced Plasticity (TWIP) Steels, Acta Mater., 2018, 142, p 283–362

I. Gutierrez-Urrutia, S. Zaefferer, and D. Raabe, The Effect of Grain Size and Grain Orientation on Deformation Twinning in a Fe-22Mn-0.6C TWIP Steel, Mater. Sci. Eng. A, 2010, 527, p 3552–3560

R. Ueji, Y. Takagi, N. Tsuchida, K. Shinagawa, Y. Tanaka, and T. Mizuguchi, Crystallographic Orientation Dependence of e-Martensite Transformation During Tensile Deformation of Polycrystalline 30% Mn Austenitic Steel, Mater. Sci. Eng. A, 2013, 576, p 14–20

Y.N. Dastur and W.C. Leslie, Mechanism of Work Hardening in Hadfield Manganese Steel, Metall. Trans. A, 1981, 12, p 749–759

L. Chen, H.S. Kim, S.K. Kim, and B.C. DeCooman, Localized Deformation Due to Portevin–LeChatelier Effect in 18Mn-0.6C TWIP Austenitic Steel, ISIJ Int., 2007, 47, p 1804–1812

L. Qian, P. Guo, F. Zhang, J. Meng, and M. Zhang, Abnormal Room Temperature Serrated Flow and Strain Rate Dependence of Critical Strain of a Fe-Mn-C Twin-Induced Plasticity Steel, Mater. Sci. Eng. A, 2013, 561, p 266–269

S.J. Lee, J. Kim, S.N. Kane, and B.C. De Cooman, On the Origin of Dynamic Strain Aging in Twinning-Induced Plasticity Steels, Acta Mater., 2011, 59, p 6809–6819

I. Karaman, H. Sehitoglu, A. Beaudoin, Y.I. Chumlyakov, H.J. Maier, and C.N. Tome, Modeling the Deformation Behavior of Hadfield Steel Single and Polycrystals Due to Twinning and Slip, Acta Mater., 2000, 48, p 2031–2047

O. Bouaziz, S. Allain, and C. Scott, Effect of Grain and Twin Boundaries on the Hardening Mechanisms of Twinning-Induced Plasticity Steels, Scr. Mater., 2008, 58, p 484–487

J.G. Sevillano, An Alternative Model for the Strain Hardening of FCC Alloys That Twin, Validated for Twinning-Induced Plasticity Steel, Scr. Mater., 2009, 60, p 336–339

D. Barbier, N. Gey, S. Allain, N. Bozzolo, and M. Humbert, Analysis of the Tensile Behavior of a TWIP Steel Based on the Texture and Microstructure Evolutions, Mater. Sci. Eng., A, 2009, 500, p 196–206

K. Renard and P.J. Jacques, On the Relationship Between Work Hardening and Twinning Rate inTWIP Steels, Mater. Sci. Eng. A, 2012, 542, p 8–14

J.E. Jin and Y.K. Lee, Strain Hardening Behavior of a Fe-18Mn-0.6C-1.5Al TWIP Steel, Mater. Sci. Eng. A, 2009, 527, p 157–161

J.E. Jin and Y.K. Lee, Effect of Al on Microstructure and Tensile Properties of C-Bearing High Mn TWIP Steel, Acta Mater., 2012, 60, p 1680–1688

I. Gutierrez-Urrutia and D. Raabe, Dislocation and Twin Substructure Evolution During Strain Hardening of an Fe-22Mn-0.6C TWIP Steel Observed by Electron Channeling Contrast Imaging, Acta Mater., 2011, 59, p 6449–6462

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng. A, 2004, 387–389, p 158–162

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck, Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels, Metall. Mater. Trans. A, 2009, 40, p 3076–3090

S. Curtze and V.T. Kuokkala, Dependence of Tensile Deformation Behavior of TWIP Steels on Stacking Fault Energy, Temperature and Strain Rate, Acta Mater., 2010, 58, p 5129–5141

J.K. Kim and B.C. De Cooman, Stacking Fault Energy and Deformation Mechanisms in Fe-xMn-0.6C-yAl TWIP Steel, Mater. Sci. Eng. A, 2016, 676, p 216–231

I. Karaman, H. Sehitoglu, K. Gall, Y.I. Chumlyakov, and H.J. Maier, Deformation of Single Crystal Hadfield Steel by Twinning and Slip, Acta Mater., 2000, 48, p 1345–1359

L. Brake, L. Kestens, and J. Penning, Direct Observation of the Twinning Mechanism in an Austenitic Fe-Mn-C Steel, Scr. Mater., 2009, 61, p 220–222

S. Sato, E.P. Kwon, M. Imafuku, K. Wagatsuma, and S. Suzuki, Microstructural Characterization of High-Manganese Austenitic Steels with Different Stacking Fault Energies, Mater. Charact., 2011, 62, p 781–788

P. Yang, Q. Xie, L. Meng, H. Ding, and Z. Tang, Dependence of Deformation Twinning on Grain Orientation in a High Manganese Steel, Scr. Mater., 2006, 55, p 629–631

L. Meng, P. Yang, Q. Xie, H. Ding, and Z. Tang, Dependence of Deformation Twinning on Grain Orientation in Compressed High Manganese Steels, Scr. Mater., 2007, 56, p 931–934

J.K. Hwang, I.C. Yi, I.H. Son, J.Y. Yoo, B. Kim, A. Zargaran, and N.J. Kim, Microstructural Evolution and Deformation Behavior of Twinning-Induced Plasticity (TWIP) Steel During Wire Drawing, Mater. Sci. Eng. A, 2015, 644, p 41–52

K. Renard, H. Idrissi, D. Schryvers, and P.J. Jacques, On the Stress State Dependence of the Twinning Rate and Work Hardening in Twinning-Induced Plasticity Steels, Scr. Mater., 2012, 66, p 966–971

H. Idrissi, K. Renard, D. Schryvers, and P.J. Jacques, On the Relationship Between the Twin Internal Structure and the Work Hardening Rate of TWIP Steels, Scr. Mater., 2010, 63, p 961–964

M. Ghasri-Khouzani and J.R. McDermid, Effect of Carbon Content on the Mechanical Properties and Microstructure Evolution of Fe-22Mn-C Steels, Mater. Sci. Eng. A, 2015, 621, p 118–127

J.K. Hwang, I.H. Son, J.Y. Yoo, A. Zargaran, and N.J. Kim, Effect of Reduction of Area on Microstructure and Mechanical Properties of Twinning-Induced Plasticity Steel During Wire Drawing, Met. Mater. Int., 2015, 21, p 815–822

J.K. Hwang, Effects of Caliber Rolling on Microstructure and Mechanical Properties in Twinning-Induced Plasticity (TWIP) Steel, Mater. Sci. Eng. A, 2018, 711, p 156–164

K. Jeong, J.E. Jin, Y.S. Jung, S. Kang, and Y.K. Lee, The Effects of Si on the Mechanical Twinning and Strain Hardening of Fe-18Mn-0.6C Twinning-Induced Plasticity Steel, Acta Mater., 2013, 61, p 3399–3410

M.G. Stout and J.A. O’Rourke, Experimental Deformation Textures of OFE Copper and 70:30 Brass From Wire Drawing, Compression, and Torsion, Metall. Trans. A, 1989, 20A, p 125–131

R.K. Chin and P.S. Stelf, A Computational Study of Strain Inhomogeneity in Wire Drawing, Int. J. Mach. Tools Manuf., 1995, 35, p 1087–1098

G.H. Hasani, R. Mahmudi, and A. Karimi-Taheri, On the Strain Inhomogeneity in Drawn Copper Wires, Int. J. Mater. Form., 2010, 3, p 59–64

J.K. Hwang, Drawing Direction Effect on Microstructure and Mechanical Properties of Twinning-Induced Plasticity Steel During Wire Drawing, J. Mater. Eng. Perform., 2019, 28, p 2834–2844

J. Chen, W. Yan, C.X. Liu, R.G. Ding, and X.H. Fan, Dependence of Texture Evolution on Initial Orientation in Drawn Single Crystal Copper, Mater. Charact., 2011, 62, p 237–242

A.A. Saleh, E.V. Pereloma, and A.A. Gazder, Texture Evolution of Cold Rolled and Annealed Fe-24Mn-3Al-2Si-1Ni-0.06C TWIP Steel, Mater. Sci. Eng. A, 2011, 528, p 4537–4549

G. Palumbo and K.T. Aust, Structure-Dependence of Intergranular Corrosion in High Purity Nickel, Acta Metall. Mater., 1990, 38, p 2343–2352

C. Efstathiou and H. Sehitoglu, Strain Hardening and Heterogeneous Deformation During Twinning in Hadfield Steel, Acta Mater., 2010, 58, p 1479–1488

Y.S. Jung, S. Kang, K. Jeong, J.G. Jung, and Y.K. Lee, The Effects of N on the Microstructures and Tensile Properties of Fe-15Mn-0.6C-2Cr-xN Twinning-Induced Plasticity Steels, Acta Mater., 2013, 61, p 6541–6548

H.K. Yang, Z.J. Zhang, and Z.F. Zhang, Comparison of Work Hardening and Deformation Twinning Evolution in Fe-22Mn-0.6C-(1.5Al) Twinning-Induced Plasticity Steels, Scr. Mater., 2013, 68, p 992–995

S. Mahajan and G.Y. Chin, Twin–Slip, Twin–Twin and Slip–Twin Interactions in Co-8 wt.% Fe Alloy Single Crystals, Acta Metall., 1973, 21, p 173–179

P. Mullner, C. Solenthaler, and M.O. Speidel, Second Order Twinning in Austenitic Steel, Acta Metall. Mater., 1994, 42, p 1727–1732

M. Bonisch, Y. Wu, and H. Sehitoglu, Hardening by Slip–Twin and Twin–Twin Interactions in FeMnNiCoCr, Acta Mater., 2018, 153, p 391–403

A. Stukowski and K. Albe, Nanotwinned fcc Metals: Strengthening Versus Softening Mechanisms, Phys. Rev. B, 2010, 82, p 224103

S. Alkan, A. Ojha, and H. Sehitoglu, Determination of Latent Hardening Response for FeNiCoCrMn for Twin–Twin Interactions, Acta Mater., 2018, 147, p 149–164

H.K. Yang, Y.Z. Tian, Z.J. Zhang, and Z.F. Zhang, Simultaneously Improving the Strength and Ductility of Fe-22Mn-0.6C Twinning-Induced Plasticity Steel Via Nitrogen Addition, Mater. Sci. Eng. A, 2018, 715, p 276–280

T.S. Byun, On the Stress Dependence of Partial Dislocation Separation and Deformation Microstructure in Austenitic Stainless Steels, Acta Mater., 2003, 51, p 3063–3071

S.M. Lee, S.J. Lee, S. Lee, J.H. Nam, and Y.K. Lee, Tensile Properties and Deformation Mode of Si-Added Fe-18Mn-0.6C Steels, Acta Mater., 2018, 144, p 738–747

K.T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Stacking Fault Energy and Plastic Deformation of Fully Austenitic High Manganese Steels: Effect of Al Additon, Mater. Sci. Eng. A, 2010, 527, p 3651–3661

V. Shterner, L.B. Timokhina, A.D. Rollett, and H. Beladi, The Role of Grain Orientation and Grain Boundary Characteristics in the Mechanical Twinning Formation in a High Manganese Twinning-Induced Plasticity Steel, Metall. Mater. Trans. A, 2018, 49, p 2597–2611

H. Beladi, I.B. Timokhina, Y. Estrin, J. Kim, B.C. De Cooman, and S.K. Kim, Orientation Dependence of Twinning and Strain Hardening Behaviour of a High Manganese Twinning Induced Plasticity Steel with Polycrystalline Structure, Acta Mater., 2011, 59, p 7787–7799

S. Kibey, J.B. Liu, D.D. Johnson, and H. Sehitoglu, Energy Pathways and Directionality in Deformation Twinning, Appl. Phys. Lett., 2007, 91, p 181916

A.H. Cottrell and B.A. Bilby, A Mechanism for the Growth of Deformation Twins in Crystals, Philos. Mag., 1951, 42, p 573–581

J.A. Venables, Deformation Twinning in Face-Centred Cubic Metals, Philos. Mag., 1961, 6, p 379–396

S. Mahajan and G.Y. Chin, Formation of Deformation Twins in fcc Crystals, Acta Metall., 1973, 21, p 1353–1363

T. Mori and H. Fujita, Dislocation Reactions During Deformation Twinning in Cu-11 at.% Al Single Crystals, Acta Metall., 1980, 28, p 771–776

Acknowledgments

This Research was supported by the Tongmyong University Research Grants 2018 (2018A016-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hwang, JK. Effect of Stress States on Twinning Behavior in Twinning-Induced Plasticity Steel. J. of Materi Eng and Perform 28, 4811–4825 (2019). https://doi.org/10.1007/s11665-019-04254-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04254-1