Abstract

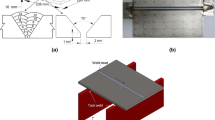

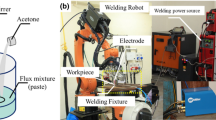

In the present study, a finite element-based 3D mesh model is used to simulate the effect of welding processes on the temperature distribution, residual stress and distortion in 11-mm-thick 2.25Cr-1Mo steel weld joints. Tungsten inert gas (TIG) and activated-TIG (A-TIG) welding processes were employed for the fabrication of weld joints. Austenite-to-bainite phase transformation is taken into account in the numerical analysis. The heat input fitting tool has been used to calibrate the heat source by matching the simulated weld bead with that of the actual weld bead. Peak temperature was higher at the weld center for A-TIG weld joint, and the weld joint exhibited a sharp temperature gradient at the weld interface. There was good agreement between the predicted and measured thermal cycles. A-TIG and multipass-TIG (MP-TIG) weld joints exhibited similar longitudinal residual stresses in heat affected zone with a difference of 50 MPa. Moreover, A-TIG weld joint fabricated by double-side welding technique employing two passes exhibited reduced distortion than MP-TIG weld joints. A higher magnitude of distortion was in MP-TIG weld joint which was attributed to more weld metal volume caused by more number of weld passes required to fill the V-groove. There was good agreement between the predicted and measured residual stress and distortion values.

Similar content being viewed by others

References

A. Trautwein, H. Mayer, W. Gysel, and B. Walser, Structure and Mechanical Properties of 2¼Cr-1Mo Cast Steel for Pressure Components with Wall Thicknesses up to 500 mm, in Application of 2¼Cr-1Mo Steel for Thick-Wall Pressure Vessels, ASTM International (1982).

K. Laha, K.B.S. Rao, and S. Mannan, Creep Behaviour of Post-weld Heat-Treated 2.25Cr-1Mo Ferritic Steel Base, Weld Metal and Weldments, Mater. Sci. Eng., A, 1990, 129, p 183–195

B. Arivazhagan and M. Vasudevan, Studies on A-TIG Welding of 2.25Cr-1Mo (P22) Steel, J. Manuf. Process., 2015, 18, p 55–59

R. Kumar, V. Tewari, and S. Prakash, Studies on Hot Corrosion of the 2.25 Cr-1Mo Boiler Tube Steel and Its Weldments in the Molten Salt Na 2 SO 4-60 pct V 2O5 Environment, Metall. Mater. Trans. A, 2007, 38, p 54–57

K. Mills, B. Keene, R. Brooks, and A. Shirali, Marangoni Effects in Welding, Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci., 1998, 356, p 911–926

M. Tanaka, T. Shimizu, T. Terasaki, M. Ushio, F. Koshiishi, and C.-L. Yang, Effects of Activating Flux on Arc Phenomena in Gas Tungsten Arc Welding, Sci. Technol. Weld. Join., 2000, 5, p 397–402

H. Fujii, T. Sato, S. Lu, and K. Nogi, Development of an Advanced A-TIG (AA-TIG) Welding Method by Control of Marangoni Convection, Mater. Sci. Eng., A, 2008, 495, p 296–303

K. Ganesh, K. Balasubramanian, M. Vasudevan, P. Vasantharaja, and N. Chandrasekhar, Effect of Multipass TIG and Activated TIG Welding Process on the Thermo-Mechanical Behavior of 316LN Stainless Steel Weld Joints, Metall. Mater. Trans. B, 2016, 47, p 1347–1362

M. Vasudevan, Effect of A-TIG Welding Process on the Weld Attributes of Type 304LN and 316LN Stainless Steels, J. Mater. Eng. Perform., 2017, 26, p 1325–1336

P.J. Withers and H. Bhadeshia, Residual Stress. Part 2–Nature and Origins, Mater. Sci. Technol., 2001, 17, p 366–375

R. Leggatt, Residual Stresses in Welded Structures, Int. J. Press. Vessels Pip., 2008, 85, p 144–151

K. Masubuchi, Analysis of Welded Structures: Residual Stresses, Distortion, and Their Consequences, Elsevier, Amsterdam, 2013

J. Francis, H. Bhadeshia, and P. Withers, Welding Residual Stresses in Ferritic Power Plant Steels, Mater. Sci. Technol., 2007, 23, p 1009–1020

D. Deng and H. Murakawa, Finite Element Analysis of Temperature Field, Microstructure and Residual Stress in Multi-pass Butt-Welded 2.25Cr–1Mo Steel Pipes, Comput. Mater. Sci., 2008, 43, p 681–695

F. Vakili-Tahami, A. Daei-Sorkhabi, M. Saeimi-S, and A. Homayounfar, 3D Finite Element Analysis of the Residual Stresses in Butt-Welded Plates with Modeling of the Electrode-Movement, J. Zhejiang Univ. Sci. A, 2009, 10, p 37–43

F. Vakili-Tahami and A. Sorkhabi, Finite Element Analysis of Thickness Effect on the Residual Stress in Butt-Welded 2.25 Cr1Mo Steel Plate, J. Appl. Sci., 2009, 9, p 1331–1337

D. Deng, Y. Tong, N. Ma, and H. Murakawa, Prediction of the Residual Welding Stress in 2.25 Cr-1Mo Steel by Taking into Account the Effect of the Solid-State Phase Transformations, Acta Metall. Sin. (Engl. Lett.), 2013, 26, p 333–339

Y. Zhou, X. Chen, Z. Fan, and S. Rao, Finite Element Modelling of Welding Residual Stress and Its Influence on Creep Behavior of a 2.25Cr-1Mo-0.25 V Steel Cylinder, Procedia Eng., 2015, 130, p 552–559

K. Ganesh, M. Vasudevan, K. Balasubramanian, P. Vasantharaja, and N. Chandrasekhar, Thermo-Mechanical Analysis of Activated Tungsten Inert Gas Welding (A-TIG) of Type 316LN Stainless Steel Thin Plates, Mater. Perform. Charact., 2018, 7, p 160–177

ESI Group SYSWELD Reference Manual Version 2006. Cedex, Paris, France, 2006

M. Zubairuddin, S. Albert, M. Vasudevan, S. Mahadevan, V. Chaudhari, and V. Suri, Numerical Simulation of Multi-pass GTA Welding of Grade 91 Steel, J. Manuf. Process., 2017, 27, p 87–97

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Sources, Metall. Trans. B, 1984, 15, p 299–305

T. Scott, G. Sangdahl, and M. Semchyshen, Application of 21/4Cr-1Mo Steel for Thick-Wall Pressure Vessels, American Society for Testing and Materials, STP755 (1982).

J. Leblond and J. Devaux, A New Kinetic Model for Anisothermal Metallurgical Transformations in Steels Including Effect of Austenite Grain Size, Acta Metall., 1984, 32, p 137–146

R. Klueh and R. Swindeman, Mechanical Properties of a Modified 21/4 Cr-1Mo Steel for Pressure Vessel Applications, No. ORNL-5995. Oak Ridge National lab, TN, USA, 1983

M. Xu, H. Lu, C. Yu, J. Xu, and J. Chen, Finite Element Simulation of Butt Welded 2 25Cr-16 W Steel Pipe Incorporating Bainite Phase Transformation, Sci. Technol. Weld. Join., 2013, 18(3), p 184–190

W.K.C. Jones and P.J. Alberry, A Model for Stress Accumulation in Steels During Welding, Met. Technol., 1977, 11, p 557–566

H. Bhadeshia, Phase Transformations Contributing to the Properties of Modern Steels, Bull. Pol. Acad. Sci. Tech. Sci., 2010, 58(2), p 255–265

H. Murakawa, M. Beres, A. Vega, S. Rashed, C.M. Davies, D. Dye, and K.M. Nikbin, Effect of Phase Transformation Onset Temperature on Residual Stress in Welded Thin Steel Plates, Trans. JWRI, 2008, 37(2), p 75–80

S. Lavanya, S. Mahadevan, and C. Mukhopadhyay, Correlation of Tensile Deformation-Induced Strain in HSLA Steel with Residual Stress Distribution, J. Mater. Eng. Perform., 2019, 28(2), p 1103–1111

R.W. Messler, Principles of Welding: Processes, Physics, Chemistry, and Metallurgy, Wiley, New York, 2008

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pavan, A.R., Arivazhagan, B., Zubairuddin, M. et al. Thermomechanical Analysis of A-TIG and MP-TIG Welding of 2.25Cr-1Mo Steel Considering Phase Transformation. J. of Materi Eng and Perform 28, 4903–4917 (2019). https://doi.org/10.1007/s11665-019-04243-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04243-4