Abstract

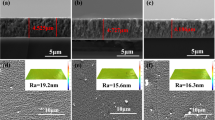

The mechanical and tribological properties of tantalum and its alloy films are greatly influenced by their phase transformation. In this study, Ta and Ta-Ag films were prepared on carbon steel substrate by DC magnetron sputtering with various sputtering powers. The amorphous and nanocrystalline Ta and Ta-Ag film were produced at different sputtering powers from 40 to 110 W. The frictional properties of Ta and Ta-Ag films were investigated by rubbing against Si3N4 ball from RT to 700 °C. The nanocrystalline Ta-Ag films shows higher hardness values (12 GPa) compared with amorphous phase. The nanocrystalline Ta90-Ag8 film shows a low friction coefficient of about 0.20-0.30 when rubbing against Si3N4 ball at 700 °C. The segregation of Ag can effectively reduce friction coefficients of Ta-Ag film at 700 °C. The Ta-Ag films show high structure stability even after friction at 700 °C.

Similar content being viewed by others

References

D.W.S.L. Lee, Phase, Residual Stress, and Texture in Triode-Sputtered Tantalum Coatings on Steel, Surf. Coat. Technol., 1998, 108-109, p 65–72

K. Valleti, A. Subrahmanyam, and S.V. Joshi, Growth of Nano Crystalline Near α Phase Tantalum Thin Films at Room Temperature Using Cylindrical Magnetron Cathode, Surf. Coat. Technol., 2008, 202(14), p 3325–3331

L. Hallmann and P. Ulmer, Effect of Sputtering Parameters and Substrate Composition on the Structure of Tantalum Thin Films, Appl. Surf. Sci., 2013, 282, p 1–6

S. Myers, J. Lin, R.M. Souza et al., The β to α Phase Transition of Tantalum Coatings Deposited by Modulated Pulsed Power Magnetron Sputtering, Surf. Coat. Technol., 2013, 214, p 38–45

A.A. Navid and A.M. Hodge, Nanostructured Alpha and Beta Tantalum Formation-Relationship Between Plasma Parameters and Microstructure, Mater. Sci. Eng., A, 2012, 536, p 49–56

W.-L. Wang, W.-C. Chen, K.-T. Peng et al., The Influence of Amorphous TaNx Under-Layer on the Crystal Growth of Over-Deposited Ta Film, Thin Solid Films, 2016, 603, p 34–38

K. Ino, T. Shinohara, T. Ushiki et al., Ion Energy, Ion Flux, Ion Species Effects on Crystallographic and Electrical Properties of Sputter-Deposited Ta Thin Films, J. Vac. Sci. Technol. A Vac. Surf. Films, 1997, 15(5), p 2627–2635

R. Knepper, B. Stevens, and S.P. Baker, Effect of oxygen on the Thermomechanical Behavior of Tantalum Thin Films During the β-α Phase Transformation, J. Appl. Phys., 2006, 100(12), p 123508

Y.M. Zhou, Z. Xie, H.N. Xiao et al., Effects of Deposition Parameters on Tantalum Films Deposited by Direct Current Magnetron Sputtering, Vacuum, 2008, 83(2), p 286–291

M. Grosser and U. Schmid, The Impact of Sputter Conditions on the Microstructure and on the Resistivity of Tantalum Thin Films, Thin Solid Films, 2009, 517(16), p 4493–4496

K. Stella, D. Bürstel, S. Franzka et al., Preparation and Properties of Thin Amorphous Tantalum Films Formed by Small e-Beam Evaporators, J. Phys. D Appl. Phys., 2009, 42(13), p 135417

Z.H. Cao, P.Y. Li, and X.K. Meng, Nanoindentation Creep Behaviors of Amorphous, Tetragonal, and bcc Ta Films, Mater. Sci. Eng. A, 2009, 516(1-2), p 253–258

M.T. Janish, W.M. Mook, and C.B. Carter, Nucleation of fcc Ta When Heating Thin Films, Scr. Mater., 2015, 96, p 21–24

J. Narayan, V. Bhosle, A. Tiwari et al., Methods for Processing Tantalum Films of Controlled Microstructures and Properties, J. Vac. Sci. Technol. A., 2006, 24(5), p 1948–1954

J. Wang, J.L. Li, H. Li et al., Friction and Wear Properties of Amorphous and Nanocrystalline Ta-Ag Films at Elevated Temperatures as Function of Working Pressure, Surf. Coat. Technol., 2018, 353(15), p 135–147

J.F. Curry, T.F. Babuska, T.A. Furnish et al., Achieving Ultralow Wear with Stable Nanocrystalline Metals, Adv. Mater., 2018, 1802026, p 1–7

W. Qin, L.C. Fu, J.J. Zhu et al., Tribological Properties of Self-Lubricating Ta-Cu films, Appl. Surf. Sci., 2018, 435, p 1105–1113

F. Zeng, Y. Gao, L. Li et al., Elastic Modulus and Hardness of Cu-Ta Amorphous Films, J. Alloys Compd., 2005, 389(1-2), p 75–79

C.M. Müller, S. Parviainen, F. Djurabekova et al., The As-Deposited Structure of Co-sputtered Cu-Ta Alloys, Studied by X-ray Diffraction and Molecular Dynamics Simulations, Acta Mater., 2015, 82, p 51–63

D.S. Stone, S. Harbin, H. Mohseni et al., Lubricious Silver Tantalate Films for Extreme Temperature Applications, Surf. Coat. Technol., 2013, 217, p 140–146

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 2011, 7(06), p 1564–1583

M. Zhang, Y.F. Zhang, P.D. Rack et al., Nanocrystalline Tetragonal Tantalum Thin Films, Scr. Mater., 2007, 57(11), p 1032–1035

A.A. Navid and A.M. Hodge, Controllable Residual Stresses in Sputtered Nanostructured Alpha-Tantalum, Scr. Mater., 2010, 63(8), p 867–870

F. Misják, P.B. Barna, and A.L. Tóth, Structure and Mechanical Properties of Cu-Ag Nanocomposite Films, Thin Solid Films, 2008, 516, p 3931–3934

J.L. Li, J. Wang, A. Kumar et al., High Temperatures Tribological Properties of Ta-Ag Films Deposited at Various Working Pressures and Sputtering Powers, Surf. Coat. Technol., 2018, 349, p 186–197

D.S. Stone, H. Gao, C. Chantharangsi et al., Load-Dependent High Temperature Tribological Properties of Silver Tantalate Coatings, Surf. Coat. Technol., 2014, 244, p 37–44

Acknowledgments

This work is financially supported by Natural Science Foundation of China (No. 51101087), China Postdoctoral Science Foundation (Nos. 2013M540450, 2014T70520), and Fundamental Research Funds for the Central Universities (No. 30917014106).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Zhang, X., Wang, J. et al. Mechanical and Frictional Performance of Ta and Ta-Ag Alloy Films Deposited at Different Sputtering Powers. J. of Materi Eng and Perform 28, 5037–5046 (2019). https://doi.org/10.1007/s11665-019-04234-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04234-5