Abstract

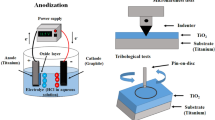

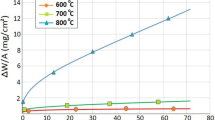

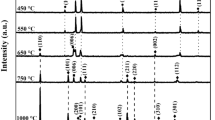

Thermal oxidation treatments are widely used to modify titanium surfaces. Thermally oxidized titanium alloys are used as biomaterials due to their better surface properties, such as corrosion resistance. However, the use of cyclic thermal treatment for this purpose has not yet been reported. This paper’s objective was to compare roughness, microhardness and corrosion resistance after cyclic and conventional isothermal heat treatments in a Ti6Al4V alloy. The heat treatments were performed over a period of 24 h with a maximum temperature of 650 °C, and cyclic conditions were executed from 200 to 400 °C for 48 cycles, each lasting 0.5 h. After the thermal treatments, roughness was measured through profilometer and atomic force microscopy, Vickers microhardness was evaluated, and polarization corrosion tests were performed in simulated body fluid. All treatments increased surface roughness, microhardness and corrosion resistance at 500 mV above open-circuit potential in polarization tests, compared to the material without oxidation. These results are associated with rutile formation, observed through XRD analysis. Although the isothermal and cyclic treatments presented similar behaviors, the 650-200 °C cyclic heat treatment provided an intermediate roughness and produced a slightly better corrosion resistance, demonstrating that cyclic thermal treatments are a viable alternative for improving titanium alloy surface properties.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

M.T. Mohammed, Z.A. Khan, and A.N. Siddiquee, Beta Titanium Alloys: The Lowest Elastic Modulus for Biomedical Applications: A Review, Int. J. Chem. Mol. Nucl. Mater. Metall. Eng., 2014, 8, p 821–827. https://doi.org/10.5281/zenodo.1094481

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia, Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants—A Review, Prog. Mater Sci., 2009, 54, p 397–425. https://doi.org/10.1016/j.pmatsci.2008.06.004

M. Niinomi, Recent Research and Development in Titanium Alloys for Biomedical Applications and Healthcare Goods, Sci. Technol. Adv. Mater., 2003, 4, p 445–454. https://doi.org/10.1016/j.stam.2003.09.002

S. Nag, R. Banerjee, and H.L. Fraser, Microstructural Evolution and Strengthening Mechanisms in Ti-Nb-Zr-Ta, Ti-Mo-Zr-Fe and Ti-15Mo Biocompatible Alloys, Mater. Sci. Eng. C, 2005, 25, p 357–362. https://doi.org/10.1016/j.msec.2004.12.013

E. Eisenbarth, D. Velten, M. Müller, R. Thull, and J. Breme, Biocompatibility of β-Stabilizing Elements of Titanium Alloys, Biomaterials, 2004, 25, p 5705–5713. https://doi.org/10.1016/j.biomaterials.2004.01.021

B.D. Boyan, T.W. Hummert, D.D. Dean, and Z. Schwartz, Role of Material Surfaces in Regulating Bone and Cartilage Cell Response, Biomaterials, 1996, 17, p 137–146. https://doi.org/10.1016/0142-9612(96)85758-9

Z. Schwartz, J.Y. Martin, D.D. Dean, J. Simpson, D.L. Cochran, and B.D. Boyan, Effect of Titanium Surface Roughness on Chondrocyte Proliferation, Matrix Production, and Differentiation Depends on the State of Cell Maturation, J. Biomed. Mater. Res., 1996, 30, p 145–155. https://doi.org/10.1002/(SICI)1097-4636(199602)30:2<145::AID-JBM3>3.0.CO;2-R

B. Chehroudi, D. McDonnell, and D.M. Brunette, The Effects of Micromachined Surfaces on Formation of Bonelike Tissue on Subcutaneous Implants as Assessed by Radiography and Computer Image Processing, J. Biomed. Mater. Res., 1998, 34, p 279–290. https://doi.org/10.1002/(SICI)1097-4636(19970305)34:3<279::AID-JBM2>3.0.CO;2-H

F. Borgioli, E. Galvanetto, F. Iozzelli, and G. Pradelli, Improvement of Wear Resistance of Ti-6Al-4V Alloy by Means of Thermal Oxidation, Mater. Lett., 2005, 59, p 2159–2162. https://doi.org/10.1016/j.matlet.2005.02.054

A. Gutiérrez, F. Pászti, A. Climent-Font, J.A. Jiménez, and M.F. López, Comparative Study of the Oxide Scale Thermally Grown on Titanium Alloys by Ion Beam Analysis Techniques and Scanning Electron Microscopy, J. Mater. Res., 2008, 23, p 2245–2253. https://doi.org/10.1557/JMR.2008.0281

S. Kumar, T.S.N. Sankara Narayanan, S. Ganesh Sundara Raman, and S.K. Seshadri, Thermal Oxidation of Ti6Al4V Alloy: Microstructural and Electrochemical Characterization, Mater. Chem. Phys., 2010, 119, p 337–346. https://doi.org/10.1016/j.matchemphys.2009.09.007

J.R. Nicholls and M.J. Bennett, Cyclic Oxidation—Guidelines for Test Standardisation, Aimed at the Assessment of Service Behaviour†, Mater. High Temp., 2000, 17, p 413–428. https://doi.org/10.1179/mht.2000.17.3.005

H.E. Evans, Stress Effects in High Temperature Oxidation of Metals, Int. Mater. Rev., 1995, 40, p 1–40. https://doi.org/10.1179/imr.1995.40.1.1

A.M. De Sousa Malafaia, V.R. do Nascimento, L. Mendes Sousa, M. Eduardo, and M.F. de Oliveira, Anomalous Cyclic Oxidation Behaviour of an Fe-Mn-Si-Cr-Ni Alloy—A Finite Element Analysis, Corros. Sci., 2019, 147, p 223–230. https://doi.org/10.1016/j.corsci.2018.11.018

A.M. de Sousa Malafaia and M.F. De Oliveira, Anomalous Cyclic Oxidation Behaviour of a Fe-Mn-Si-Cr-Ni Shape Memory Alloy, Corros. Sci., 2017, 119, p 112–117. https://doi.org/10.1016/j.corsci.2017.02.026

G. Fargas, J.J. Roa, B. Sefer, R. Pederson, M.L. Antti, and A. Mateo, Influence of Cyclic Thermal Treatments on the Oxidation Behavior of Ti-6Al-2Sn-4Zr-2Mo Alloy, Mater. Charact., 2018, 145, p 218–224. https://doi.org/10.1016/j.matchar.2018.08.049

C.C. Chou, P.W. Kao, and G.H. Cheng, Accelerated Spheroidization of Hypoeutectoid Steel by the Decomposition of Supercooled Austenite, J. Mater. Sci., 1986, 21, p 3339–3344. https://doi.org/10.1007/BF00553377

W. Szkliniarz, J. Chrapoński, A. Kościelna, and B. Serek, Substructure of Titanium Alloys After Cyclic Heat Treatment, Mater. Chem. Phys., 2003, 81, p 538–541. https://doi.org/10.1016/S0254-0584(03)00069-5

Z. Lv, X. Ren, Z. Li, Z. Lu, M. Gao, and T. Beijing, Effects of Two Different Cyclic Heat Treatments on Microstructure and Mechanical Properties of Ti-V Microalloyed Steel, Mater. Res., 2015, 18, p 304–312. https://doi.org/10.1590/1516-1439.302414

S. Izman, M. Rafiq, M. Anwar, E.M. Nazim, R. Rosliza, A. Shah, M.A. Hass, Surface Modification Techniques for Biomedical Grade of Titanium Alloys: Oxidation, Carburization and Ion Implantation Processes, in: Titanium Alloys-Towards Achieving Enhanced Properties for Diversified Applications (InTech, 2012), pp. 201–228. https://doi.org/10.5772/36318

T. Kokubo and H. Takadama, How Useful is SBF in Predicting in Vivo Bone Bioactivity?, Biomaterials, 2006, 27, p 2907–2915. https://doi.org/10.1016/J.BIOMATERIALS.2006.01.017

C.N. Elias, Y. Oshida, J.H.C. Lima, and C.A. Muller, Relationship Between Surface Properties (Roughness, Wettability and Morphology) of Titanium and Dental Implant Removal Torque, J. Mech. Behav. Biomed. Mater., 2008, 1, p 234–242. https://doi.org/10.1016/j.jmbbm.2007.12.002

A. Bloyce, P. Qi, H. Dong, and T. Bell, Surface Modification of Titanium Alloys for Combined Improvements in Corrosion and Wear Resistance, Surf. Coat. Technol., 1998, 107, p 125–132. https://doi.org/10.1016/S0257-8972(98)00580-5

H.J. Kim, S.H. Kim, M.S. Kim, E.J. Lee, H.G. Oh, W.M. Oh, S.W. Park, W.J. Kim, G.J. Lee, N.G. Choi, J.T. Koh, D.B. Dinh, R.R. Hardin, K. Johnson, V.L. Sylvia, J.P. Schmitz, and D.D. Dean, Varying Ti-6Al-4V Surface Roughness Induces Different Early Morphologic and Molecular Responses in MG63 Osteoblast-Like Cells, J. Biomed. Mater. Res. Part A, 2005, 74A, p 366–373. https://doi.org/10.1002/jbm.a.30327

L. Ponsonnet, K. Reybier, N. Jaffrezic, V. Comte, C. Lagneau, M. Lissac, and C. Martelet, Relationship Between Surface Properties (Roughness, Wettability) of Titanium and Titanium Alloys and Cell Behaviour, Mater. Sci. Eng. C, 2003, 23, p 551–560. https://doi.org/10.1016/S0928-4931(03)00033-X

X. Zhu, J. Chen, L. Scheideler, R. Reichl, and J. Geis-Gerstorfer, Effects of Topography and Composition of Titanium Surface Oxides on Osteoblast Responses, Biomaterials, 2004, 25, p 4087–4103. https://doi.org/10.1016/j.biomaterials.2003.11.011

A.M. Huntz, Stresses in NiO, Cr2O3 and Al2O3 Oxide Scales, Mater. Sci. Eng. A, 1995, 201, p 211–228. https://doi.org/10.1016/0921-5093(94)09747-X

S. Zeng, A. Zhao, H. Jiang, X. Fan, X. Duan, and X. Yan, Cyclic Oxidation Behavior of the Ti-6Al-4V Alloy, Oxid. Met., 2014, 81, p 467–476. https://doi.org/10.1007/s11085-013-9458-z

S.S. Jiang and K.F. Zhang, Study on Controlling Thermal Expansion Coefficient of ZrO2-TiO2 Ceramic Die for Superplastic Blow-Forming High Accuracy Ti-6Al-4V Component, Mater. Des., 2009, 30, p 3904–3907. https://doi.org/10.1016/J.MATDES.2009.03.023

A.J. Spark, I. Cole, D. Law, D. Marney, and L. Ward, Investigation of Agar as a Soil Analogue for Corrosion Studies, Mater. Corros., 2016, 67, p 7–12. https://doi.org/10.1002/maco.201508312

Acknowledgments

The authors would like to acknowledge FAPEMIG—Minas Gerais State Agency for Research and Development for the undergraduate research scholarship. We are also grateful to Prof. Dr. Lecino Caldeira for XRD measurements, Prof. Dr. Thalita Chiaramonte for AFM measurements and CMTC—Grenoble INP for SEM characterizations and also XRD tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maestro, C.A.R., Bueno, A.H.S. & de Sousa Malafaia, A.M. Cyclic Thermal Oxidation Evaluation to Improve Ti6Al4V Surface in Applications as Biomaterial. J. of Materi Eng and Perform 28, 4991–4997 (2019). https://doi.org/10.1007/s11665-019-04220-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04220-x