Abstract

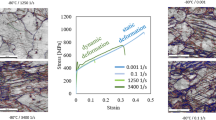

The dynamic mechanical behavior of aluminum alloy 2519A-T9I6 has been investigated by a split Hopkinson bar at temperature range from 298 to 523 K and at strain rates of from 103 to 5 × 103 s−1 in this study. The results show that both the strain rate and test temperature have a significant effect on the dynamic behavior and microstructure evolution of aluminum alloy 2519A-T9I6. Under similar strain rate, the strengthening effect of strain rate decreases with the increase in the test temperature. Moreover, the dynamic yield strength at above 423 K drops sharply at the strain rate of about 5000 s−1, which is attributed to the flow softening caused by decomposition of θ′ precipitates at high strain rate and high temperature.

Similar content being viewed by others

References

E.A. Starke, Jr, and J.T. Staley, Application of Modern Aluminum Alloys to Aircraft, Prog. Aerosp. Sci., 1996, 32(2), p 131–172

J.J. Fisher, Jr., L.S. Kramer, and J.R. Pickens, Aluminum Alloy 2519 in Military Vehicles, Adv. Mater. Processes, 2002, 160(9), p 43–46

L.S. Kramer, T.P. Blair, S.D. Blough, J.J. Fisher, Jr., and J.R. Pickens, Stress-corrosion Cracking Susceptibility of Various Product Forms of Aluminum Alloy 2519, J. Mater. Eng. Perform., 2002, 11(6), p 645–650

G. Gu, L.Y. Ye, X.M. Zhang, H.C. Jiang, D.X. Sun, and P. Zhang, Effects of Interrupted Ageing on Microstructure and Mechanical Properties of 2519A Aluminum Alloy, Chin. J. Nonferr. Met., 2013, 23(8), p 2098–2103

L.Y. Ye, G. Gu, X.M. Zhang, D.X. Sun, H.C. Jiang, and P. Zhang, Dynamic Properties Evaluation of 2519A Aluminum Alloy Processed by Interrupted Aging, Mater. Sci. Eng. A, 2014, 590(1), p 97–100

G. Gu, L.Y. Ye, H.C. Jiang, D.X. Sun, P. Zhang, and X.M. Zhang, Effects of T9I6 Thermo-mechanical Process on Microstructure, Mechanical Properties and Ballistic Resistance of 2519A Aluminum Alloy, Trans. Nonferr. Met. Soc. China, 2014, 24(7), p 2295–2300

D.X. Sun, X.M. Zhang, L.Y. Ye, G. Gu, H.C. Jiang, and G.X. Hui, Evolution of θ′ Precipitate in Aluminum Alloy 2519A Impacted by Split Hopkinson Bar, Mater. Sci. Eng. A, 2015, 620, p 241–245

C. Perrin and W.M. Rainforth, The Coarsening of θ Precipitates in an Al-4WT% Cu Alloy as a Result of Frictional Heating, Scr. Mater., 1996, 34(6), p 877–881

Z.G. Gao, X.M. Zhang, Y.S. Zhao, M.A. Chen, and H.J. Li, The Effect of Strain Rate on the Microstructure of 2519A Aluminium Alloy Plate Impacted at 573K, J. Alloy. Compd., 2009, 481(1–2), p 422–426

Z.G. Gao, X.M. Zhang, and M.A. Chen, Influence of Strain Rate on the Precipitate Microstructure in Impacted Aluminum Alloy, Scr. Mater., 2008, 59(9), p 983–986

W.H. Liu, Z.T. He, Y.Q. Chen, and S.W. Tang, Dynamic Mechanical Properties and Constitutive Equations of 2519A Aluminum Alloy, Trans. Nonferr. Met. Soc. China, 2014, 24(7), p 2179–2186

A. Azimi, G.M. Owolabi, H. Fallahdoost, N. Kumar, and G. Warner, High Strain Rate Behavior of Ultrafine Grained AA2519 Processed via Multi Axial Cryogenic Forging, Metals, 2019, 9, p 115

A. Azimi, G.M. Owolabi, H. Fallahdoost, N. Kumar, and G. Warner, Dynamic Failure Investigation in Ultrafine Grained AA2219: Mechanical and Microstructural Analysis, Metals and Materials International, 2019, p 1–12

A.T. Olasumboye, G.M. Owolabi, A.G. Odeshi, N. Yilmaz, and A. Zeytinci, Dynamic Behavior of AA2519-T8 Aluminum Alloy Under High Strain Rate Loading in Compression, J. Dyn. Behav. Mater., 2018, 4(1), p 1–11

G.M. Owolabi, D.T. Bolling, A.G. Odeshi, H.A. Whitworth, N. Yilmaz, and A. Zeytinci, The Effects of Specimen Geometry on the Plastic Deformation of AA 2219-T8 Aluminum Alloy Under Dynamic Impact Loading, J. Mater. Eng. Perform., 2017, 26(12), p 1–10

G.M. Owolabi, D.T. Bolling, A.A. Tiamiyu, R. Abu, A.G. Odeshi, and H.A. Whitworth, Shear Strain Localization in AA 2219-T8 Aluminum Alloy at High Strain Rates, Mater. Sci. Eng. A, 2016, 655(2), p 212–220

D.X. Sun, X.M. Zhang, L.Y. Ye, X.H. Gui, H.C. Jiang, and G. Gu, Comparative Study of the Dynamic Mechanical Behavior of Aluminum Alloy 2519A and 7039, Mater. Sci. Eng. A, 2015, 640, p 165–170

S.Y. Hu, M.I. Baskes, M. Stan, and L.Q. Chen, Atomistic Calculations of Interfacial Energies, Nucleus Shape and Size of θ′ Precipitates in Al–Cu Alloys, Acta Mater., 2006, 54(18), p 4699–4707

Y. Feng, Z.Z. Zhu, F.Q. Zu, S.S. Hu, and P. Yi, Strain Rate Effects on the Compressive Property and the Energy-absorbing Capacity of Aluminum Alloy Foams, Mater. Charact., 2001, 47(5), p 417–422

R. Saha and R.K. Ray, Microstructural and Textural Changes in a Severely Cold Rolled Boron-Added Interstitial-free Steel, Scr. Mater., 2007, 57(9), p 841–844

D.O. Ovono, I. Guillot, and D. Massinon, Determination of the Activation Energy in a Cast Aluminium Alloy by TEM and DSC, J. Alloy. Compd., 2007, 432(1), p 241–246

H. Fara and R.W. Balluffi, Analysis of Diffusion in Media Undergoing Deformation, J. Appl. Phys., 1958, 29(7), p 1133–1134

G.R. Love, Dislocation Pipe Diffusion, Acta Metall., 1964, 12(6), p 731–737

E.W. Hart, On the Role of Dislocations in Bulk Diffusion, Acta Metall., 1957, 5(10), p 597–597

A.W. Zhu, J. Chen, and E.A. Starke, Jr., Precipitation Strengthening of Stress-aged Al–xCu Alloys, Acta Mater., 2000, 48(9), p 2239–2246

Acknowledgment

This study was supported by the National Key Research and Development Program of China (No. 2016YFB0300901), which is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ye, Ly., Dong, Y., Zhang, Y. et al. Effect of Test Temperature and Strain Rate on Dynamic Mechanical Behavior of Aluminum Alloy 2519A. J. of Materi Eng and Perform 28, 4964–4971 (2019). https://doi.org/10.1007/s11665-019-04216-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04216-7