Abstract

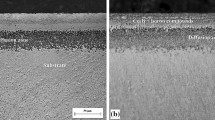

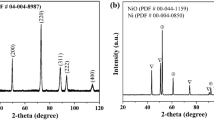

New results about the wear resistance of CoB-Co2B coatings under dry sliding conditions were estimated in this work. The cobalt boride coatings were developed at the surface of the ASTM F1537 alloy by means of the powder-pack boriding process using two experimental conditions: 1223 K with 6 h of exposure and 1273 K with 10 h of exposure. Before the sliding wear tests, Vickers depth-sensing microindentation tests were conducted on the cross section of the cobalt boride coatings to estimate the distribution of hardness, Young’s modulus, and residual stresses. Otherwise, the sliding wear tests were performed on both boriding conditions and on the untreated material, using a ball-on-flat configuration comprised of an alumina ball as a counterpart with applied loads between 5 and 20 N. The wear rates of the borided ASTM F1537 alloy were ranged between 4.02 and 8.91 × 10−6 mm3 N−1 m−1 compared with the values of the untreated material (13.90 and 15.78 × 10−6 mm3 N−1 m−1) for the overall set of experimental conditions; nevertheless, the influence of boriding conditions (1273 K with 10 h of exposure) tended to increase the CoB coating thickness, developing a more brittle layer that decreased the sliding wear resistance at the surface of the borided ASTM F1537 alloy. Finally, the presence of failure mechanisms on the surface of the wear tracks was analyzed for both borided ASTM F1537 alloy and untreated material.

Similar content being viewed by others

References

R. Pilliar and S. Ramsay, Cobalt-Base Alloy, Materials for Medical Device, 1st ed., R. Narayan, Ed., ASM International, Russell Township, 2012, p 211–222

H. Beutler, M. Lehman, and G. Stahli, Wear Behavior of Medical Engineering Materials, Wear, 1975, 33, p 337–350

H. Matusiewicz, Potential Release of in vivo Trace Metals from Metallic Medical Implants in the Human Body: from Ions to Nanoparticles—a Systematic Analytical Review, Acta Biomater., 2014, 10, p 2379–2403

A.C. Fraker, Corrosion of Metallic Implants and Prosthetic Devices, Corrosion-Metals Handbook, 1st ed., L.J. Korb, Ed., ASM International, Russell Township, 1987, p 1324–1335

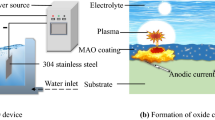

H. Liang, B. Shi, A. Fairchild, and T. Cale, Applications of Plasma Coatings in Artificial Joints: an Overview, Vacuum, 2004, 73, p 317–326

L. Kuncicka, R. Kocich, and T.C. Lowe, Advances in Metals and Alloys for Joint Replacement, Prog. Mater. Sci., 2017, 88, p 232–280

J.M. Johnston, M. Jubinsky, and S.A. Catledge, Plasma Boriding of a Cobalt-Chromium Alloy as an Interlayer for Nanostructured Diamond Growth, Appl. Surf. Sci., 2015, 328(2015), p 133–139

I. Campos-Silva, D. Bravo-Bárcenas, H. Cimenoglu, U. Figueroa-López, M. Flores-Jiménez, and M. Meydanoglu, The Boriding Process in CoCrMo Alloy: Fracture Toughness in Cobalt Boride Coatings, Surf. Coat. Technol., 2014, 260, p 362–368

D. Mu, C. Yang, B. Shen, and H. Jiang, Oxidation Resistance of Borided Pure Cobalt, J. Alloys Compd., 2009, 479, p 629–633

K.G. Anthymidis, G. Stergioudis, D. Roussos, P. Zinoviadis, and D.N. Tsipas, Boriding of Ferrous and Non-Ferrous Metals and Alloys in Fluidised Bed Reactor, Surf. Eng., 2002, 18, p 255–259

D. Bravo-Bárcenas, I. Campos-Silva, H. Cimenoglu, J. Martínez-Trinidad, M. Flores-Jiménez, and H. Martínez-Gutiérrez, Characterisation of CoB-Co2B Coatings by the Scratch Test, Surf. Eng., 2016, 32, p 570–577

D. Mu and B. Shen, Mechanical and Dry-Sliding Wear Properties of Boronized Pure Cobalt Using Boronizing Powders with SiC as Diluent, Surf. Coat. Technol., 2013, 236, p 102–106

I. Campos-Silva, D. Bravo-Bárcenas, A. Meneses-Amador, M. Ortiz-Dominguez, H. Cimenoglu, U. Figueroa-López, and J. Andraca-Adame, Growth Kinetics and Mechanical Properties of Boride Layers Formed at the Surface of the ASTM F-75 Biomedical Alloy, Surf. Coat. Technol., 2013, 25, p 402–414

A. Meneses-Amador, D. Sandoval-Juárez, G.A. Rodríguez-Castro, D. Fernández-Valdés, I. Campos-Silva, R.C. Vega-Morón, and J.L. Arciniega-Martínez, Contact Fatigue Performance of Cobalt Boride Coatings, Surf. Coat. Technol., 2018, 353, p 346–354

D. Mu, B. Shen, and X. Zhao, Effects of Boronizing on Mechanical and Dry-Sliding Wear Properties of CoCrMo Alloy, Mater. Des., 2010, 31, p 3933–3936

G.A. Rodríguez-Castro, C.D. Reséndiz-Calderón, L.F. Jiménez-Tinoco, A. Meneses-Amador, E.A. Gallardo-Hernández, and I.E. Campos-Silva, Micro-Abrasive Wear Resistance of CoB/Co2B Coatings Formed in CoCrMo Alloy, Surf. Coat. Technol., 2015, 284, p 258–263

M.A. Wimmer, C. Sprecher, R. Hauert, G. Tager, and A. Fischer, Tribochemical Reaction on Metal-on-Metal Hip Joint Bearings: a Comparison Between in vitro and in vivo Results, Wear, 2003, 255, p 1007–1014

R. Pourzal, I. Catelas, R. Theissmann, C. Kaddick, and A. Fischer, Characterization of Wear Particles Generated from CoCrMo Alloy Under Sliding Wear Conditions, Wear, 2011, 271, p 1658–1666

W.C. Oliver and G.M. Pharr, An improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583

K.S. Chen, T.C. Chen, and K.S. Ou, Development of Semi-Empirical Formulation for Extracting Materials Properties from Nanoindentation Measurements: Residual Stresses, Substrate Effect and Creep, Thin Solid Films, 2008, 516, p 1931–1940

V.I. Dybkov, Growth of Boride Layers on the 13% Cr Steel Surface in a Mixture of Amorphous Boron and KBF4, J. Mater. Sci., 2007, 42, p 6614–6627

I. Campos-Silva, A.D. Contla-Pacheco, A. Ruiz-Rios, J. Martínez-Trinidad, G. Rodríguez-Castro, A. Meneses-Amador, and W.D. Wong-Angel, Effect of Scratch Tests on the Adhesive and Cohesive Properties of Borided Inconel 718 Superalloy, Surf. Coat. Technol., 2018, 349, p 917–927

Y. Sun and T. Bell, Dry Sliding Wear Resistance of Low Temperature Plasma Carburized Austenitic Stainless Steel, Wear, 2002, 253, p 689–693

A.V. Byakova, Influence of Texture on the Strength and Supporting Capacity of Boride Coatings, Poroshkovaya Metallurgiya, 1993, 4, p 36–43

H. Cimenoglu, E. Atar, and A. Motallebzadeh, High Temperature Tribological Behaviour of Borided Surfaces Based on the Phase Structure of the Boride Layer, Wear, 2014, 309, p 152–158

R. Carrera-Espinoza, U. Figueroa-López, J. Martínez-Trinidad, I. Campos-Silva, E. Hernández-Sánchez, and A. Motallebzadeh, Tribological Behavior of Borided AISI, 1018 Steel Under Linear Reciprocating Sliding Conditions, Wear, 2016, 362–363, p 1–7

F. Toschi, C. Melandri, P. Pinasco, E. Roncari, S. Guicciardi, and G. de Portu, Influence of Residual Stresses on the Wear Behavior of Alumina/Alumina-Zirconia Laminated Composites, J. Am. Ceram. Soc., 2003, 86, p 1547–1553

I. Hutchings and P. Shipway, Tribology: Friction and Wear of Engineering Materials, 2nd ed., Buttherworth-Heinemann, Oxford, 2017, p 107–164

T.S. Eyre, Effect of Boronising on Friction and Wear of Ferrous Metals, Wear, 1975, 34, p 383–397

T.E. Fischer, M.P. Anderson, and S. Jahanmir, Influence of Fracture Toughness on the Wear Resistance of Yttria-Doped Zirconium Oxide, J. Am. Ceram. Soc., 1989, 72, p 252–257

B.R. Lawn and D.B. Marshall, Hardness, Toughness and Brittleness: an Indentation Analysis, J. Am. Ceram. Soc., 1979, 62, p 347–350

I. Campos-Silva, D. Bravo-Bárcenas, M. Flores-Jiménez, I. Arzate-Vázquez, C. López-García, and S. Bernabé-Molina, Diffusion Boride Coatings in CoCrMo Alloy and Some Indentation Properties, Metallogr. Microstruct. Anal., 2015, 4, p 158–168

T.E. Tallian, On Competing Failure Modes in Rolling Contact, ASLE Trans., 1967, 10, p 418–439

K. Holmberg and A. Matthews, Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering, 2nd ed., B.J. Briscoe, Ed., Elsevier Publications, Amsterdam, 1994, p 57–58

K.H. Habig and R. Chatterjee-Fischer, Wear Behaviour of Boride Layers on Alloyed Steels, Tribol. Int., 1981, 14, p 209–215

Acknowledgments

This work was supported by the research Grant 20195029 of the Instituto Politécnico Nacional of Mexico.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Campos-Silva, I., Vega-Morón, R.C., Reséndiz-Calderón, C.D. et al. Dry Sliding Wear Resistance of Cobalt Boride Coatings Formed on ASTM F1537 Alloy. J. of Materi Eng and Perform 28, 2399–2410 (2019). https://doi.org/10.1007/s11665-019-04012-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04012-3