Abstract

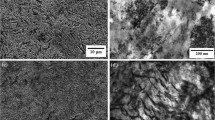

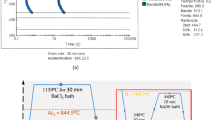

In this research work, cost-effective structural material synthesis routes have been adopted in the form of thermal cycling designed and applied on a low-cost material (AISI 1010 steel). The main synthesis route consists of two-step thermal cycling (designed with respect to iron–carbon phase diagram) combining short-duration holding in upper critical and intercritical temperature regimes and different cooling conditions (forced air cooling and ice-brine quenching). Accordingly, the adopted hierarchical design approach (from nanoscale onwards) with a combination of hard and soft phases (to attain an adequate balance between mutually exclusive strength and ductility properties) results in origin of a novel microstructure. The microstructure consists of dislocation-enriched martensite regions (possessing plate and lath morphologies in 1:4 ratio) containing nanosized cementite particles and α-ferrite regions containing submicroscopic cementite particles. As a consequence, an excellent combination of strength (UTS = 905 MPa) and ductility (%Elongation = 17) is achieved in the synthesized material.

Similar content being viewed by others

References

M.E. Launey, M.J. Buehler, and R.O. Ritchie, On the Mechanistic Origins of Toughness in Bone, Annu. Rev. Mater. Res., 2010, 40, p 25–53. https://doi.org/10.1146/annurev-matsci-070909-104427

K.J. Koester, J.W. Ager, and R.O. Ritchie, The True Toughness of Human Cortical Bone Measured with Realistically Short Cracks, Nat. Mater., 2008, 7, p 672–677. https://doi.org/10.1038/nmat2221

R.K. Nalla, J.J. Kruzic, J.H. Kinney, and R.O. Ritchie, Mechanistic Aspects of Fracture and R-Curve Behavior in Human Cortical Bone, Biomaterials, 2005, 26, p 217–231. https://doi.org/10.1016/j.biomaterials.2004.02.017

Anon, HSM Wire International, Inc (2013), www.hsmwire.com

V.D. Eisenhuettenleute, A Handbook for Materials Research and Engineering, Springer, Berlin, 1993, p 78–117

H.K.D.H. Bhadeshia, Nanostructured Bainite, Proc. R. Soc. A, 2010, 466, p 3–18. https://doi.org/10.1098/rspa.2009.0407

H. Jafarian, Characteristics of Nano/Ultrafine-Grained Austenitic TRIP Steel Fabricated by Accumulative Roll Bonding and Subsequent Annealing, Mater. Charact., 2016, 114, p 88–96

H.R. Jafarian, S.H. Mousavi Anijdan, A.R. Eivani, and N. Park, A Comprehensive Study of Microstructure Development and Its Corresponding Tensile Properties in Nano/Ultrafine-Grained Metastable Austenitic Steel During Accumulative Roll Bonding (ARB), Mater. Sci. Eng., A, 2017, 703, p 196–204

R. Grange, Strengthening by Austenite Grain Refinement, Trans. Am. Soc. Metals, 1966, Met.1, p 26–29

A. Anashkin, Heat Cycling of Carbon Steel Wire, Metal Sci. Heat Treat., 1987, Met.2, p 10–14

K. Nakazawa, Y. Kawabe, and S. Muneki, Grain Refinement of High Strength Maraging Steel Through Cyclic Heat Treatment, Mater. Sci. Eng., 1978, 33, p 49–56

J. Wang, S. Lu, L. Rong, and D. Li, Thermal Cycling, Microstructure and Mechanical Properties of 9Cr2WVTa Steel Welds, J. Mater. Process. Technol., 2015, 222, p 434–443. https://doi.org/10.1016/j.jmatprotec.2015.03.017

I.N. Katsina, Ph.D. Thesis, Cranfield University, September 2012, pp. 1–306

O.P. Bondareva, E.V. Sedov, and I.L. Gonik, Effect of Thermal Cycling Treatment on Structure and Properties of Ferritic-Austenitic Steel Welded Joint Heat-Affected Zone Metal, Chem. Pet. Eng., 2016, 52, p 506–511. https://doi.org/10.1007/s10556-016-0223-4

K.W. Andrews, Empirical Formulae for the Calculation of Some Transformation Temperatures, J. Iron Steel Inst. Jpn., 1965, 203, p 721–727

Anon, Alloy Phase Diagram, Vol 3, Ohio, ASM international, 1992, p 527

Y.L. Tian and R.W. Kraft, Mechanisms of Pearlite Spheroidisation, Metall. Trans. A, 1987, 18, p 1403–1414. https://doi.org/10.1007/BF02646654

J. Maity, A. Saha, D.K. Mondal, and K. Biswas, Mechanism of Accelerated Spheroidization of Steel During Cyclic Heat Treatment Around the Upper Critical Temperature, Philos. Mag. Lett., 2013, 93, p 231–237. https://doi.org/10.1080/09500839.2012.758390

Anon, Properties and Selection of Metals, Metals Handbook, Vol 1, 8th ed., T. Lymon, Ed., American Society of Metals, Ohio, 1961, p 54

N.Ya. Rokhmanov, A.F. Sirenko, and S.A. Bakharev, Thermal Expansion of Cementite in Hypereutectoid Iron-Carbon Alloy, Met. Sci. Heat Treat., 1997, 39, p 7–10. https://doi.org/10.1007/BF02467199

U.G.K. Wegst and M.F. Ashby, The Mechanical Efficiency of Natural Materials, Philos. Mag., 2004, 84, p 2167–2181. https://doi.org/10.1080/14786430410001680935

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Subhani, A.R., Mondal, D.K., Mondal, C. et al. Development of a High-Strength Low-Carbon Steel with Reasonable Ductility through Thermal Cycling. J. of Materi Eng and Perform 28, 2192–2201 (2019). https://doi.org/10.1007/s11665-019-03969-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03969-5