Abstract

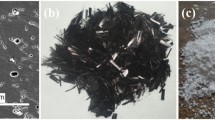

In this study, Al-based metal matrix composite (MMC) with diamond and cBN abrasive grains was fabricated by a centrifugal mixed-powder method (CMPM). Two types of CMPM experiments with and without consolidated part were carried out. It was found that the MMC dispersed with diamond and cBN abrasive grains can be successfully fabricated by CMPM. In case of CMPM without consolidated part, the homogeneous distribution of the abrasive grains along hoop direction in the MMC could not be achieved due to slumping of mixed-powder by gravity. On the other hand, modified CMPM using consolidated part could fabricate a MMC with uniform distribution of abrasive grains along hoop direction. Grinding wheels were manufactured using fabricated MMC samples, and drilling experiments were carried out on carbon fiber reinforced plastic (CFRP). It was found that the better drilling performance was found for the Al/Diamond grinding wheel rather than Al/cBN grinding wheel. Therefore, it can be concluded that the grinding wheel was not subjected at high temperature even though the drilling was carried out under dry condition.

Similar content being viewed by others

References

W.-C. Chen, Some Experimental Investigations in the Drilling of Carbon Fiber-Reinforced Plastic (CFRP) Composite Laminates, Int. J. Mach. Tools Manuf., 1997, 37(8), p 1097–1108

Y. Karpat, B. Deger, and O. Bahtiyar, Drilling Thick Fabric Woven CFRP Laminates with Double Point Angle Drills, J. Mater. Process. Technol., 2012, 212(10), p 2117–2127

S.C. Lin and I.K. Chen, Drilling Carbon Fiber-Reinforced Composite Material at High Speed, Wear, 1996, 194(1–2), p 156–162

D.F. Liu, Y.J. Tang, and W.L. Cong, A Review of Mechanical Drilling for Composite Laminates, Compos. Struct., 2012, 94(4), p 1265–1279

Y. Watanabe, E. Miura-Fujiwara, H. Sato, K. Takekoshi, H. Tsuge, T. Kaga, N. Bando, S. Yamagami, K. Kurachi, and H. Yokoyama, Fabrication of Functionally Graded Grinding Wheel by a Centrifugal Mixed-Powder Method for CFRP-Drilling Applications, Int. J. Mater. Prod. Technol., 2011, 42(1–2), p 29–45

H. Tsuge, K. Takekoshi, S. Yamagami, T. Kaga, N. Bando, M. Kamakura, and Y. Watanabe, Novel Drilling Method for CFRP with Dual-Axes-Driving Grindstone, J. Jpn. Soc. Abrasive Technol., 2012, 56(9), p 612–617 (in Japanese)

H. Tsuge, D. Ogawa, N. Bando, T. Kaga, and Y. Watanabe, Grinding Performance of Diamond Grinding Wheels Drilling of CFRP by a Dual-Axis-Driven Mechanism, J. Jpn. Soc. Abrasive Technol., 2014, 58(3), p 168–172 (in Japanese)

T. Kunimine, H. Tsuge, D. Ogawa, M. Yamada, H. Sato, and Y. Watanabe, Drilling CFRP Laminates by Dual-axis Grinding Wheel System with Copper/Diamond Functionally Graded Grinding Wheel, J. Manuf. Sci. Eng., 2018, 140(7), p 071011-1–071011-7

Y. Watanabe, Y. Inaguma, H. Sato, and E. Miura-Fujiwara, A Novel Fabrication Method for Functionally Graded Materials under Centrifugal Force: The Centrifugal Mixed-Powder Method, Materials, 2009, 2, p 2510–2525

S. El-Hadad, H. Sato, E. Miura-Fujiwara, and Y. Watanabe, Fabrication of Al/Al3Ti Functionally Graded Materials by Reaction Centrifugal Mixed-Powder Method, Jpn. J. Appl. Phys., 2011, 50(1), p 01AJ02 (7 pages)

H. Sato, A. Mizuno, Y. Mamiya, M. Yamada, and Y. Watanabe, Improvement of Bonding Force Between Abrasive Grains and Matrix in Cu/Diamond Composite Fabricated by Centrifugal Mixed-Powder Method, Mech. Eng. J., 2016, 3(6), p 16-00297 (10 pages)

T. Kunimine, H. Sato, E. Miura-Fujiwara, and Y. Watanabe, Chap. 2 New Processing Routes for Functionally Graded Materials and Structures through a Combination of Powder Metallurgy and Casting, Advances in Functionally Graded Materials and Structures, F. Ebrahimi, Ed., InTech - Open Access Publisher, Rijeka, 2016, p 33–48 ISBN 978-953-51-2274-6

S. Jamian, Y. Watanabe, and H. Sato, Formation of Compositional Gradient in Al/SiC FGMs Fabricated under Huge Centrifugal Forces using Solid-Particle and Mixed-Powder Methods, Ceram. Inter., 2018. https://doi.org/10.1016/j.ceramint.2018.08.315.

N. Toyofuku, N. Yamasaki, Y. Kodera, M. Ohyanagi, and Z.A. Munir, Turbostatic Boron Nitride Consolidated by SPS, J. Ceram. Soc. Jpn., 2009, 117(1362), p 189–193

P. Klimczyk, P. Figiel, I. Petrusha, and A. Olszyna, Cubic Boron Nitride Based Composites for Cutting Applications, J. Achiev. Mater. Manuf. Eng., 2011, 44(2), p 198–204

S.N. Monteiro, A.L.D. Skury, M.G. de Azevedo, and G.S. Bobrovnitchii, Cubic Boron Nitride Competing with Diamond as a Superhard Engineering Material—an Overview, J. Mater. Res. Technol., 2013, 2(1), p 68–74

A. Caggiano and R. Teti, CBN Grinding Performance Improvement in Aircraft Engine Components Manufacture, Procedia CIRP, 2013, 9, p 109–114

T. Kunimine, M. Shibuya, H. Sato, and Y. Watanabe, Fabrication of Copper/Diamond Functionally Graded Materials for Grinding Wheels by Centrifugal Sintered-Casting, J. Mater. Process. Technol., 2015, 217, p 294–301

P. Porion, N. Sommier, and P. Evesque, Dynamics of Mixing and Segregation Processes of Grains in 3D Blender by NMR Imaging Investigation, Europhys. Lett., 2000, 50(3), p 319–325

Y. Watanabe, S. Taniai, and H. Sato, Fabrication of Grain Refiners with High Volume Fraction of Al2.7Fe0.3Ti Heterogeneous Nucleation Site Particles by Spark Plasma Sintering, Jpn. J. Appl. Phys., 2019, 58(1) (in printing)

Y. Omori, An Introduction to Roundness Measurement, J. Jpn. Soc. Precis. Eng., 2016, 82(9), p 803–806 (in Japanese)

M. Hotta and T. Goto, Densification and Microstructure of Al2O3-cBN Composites Prepared by Spark Plasma Sintering, J. Ceram. Soc. Jpn., 2008, 116(6), p 744–748

X. Wang, A. Jha, and R. Brydson, In Situ Fabrication of Al3Ti Particle Reinforced Aluminium Alloy Metal-Matrix Composites, Mater. Sci. Eng. A, 2004, 364(1–2), p 339–345

H. Fukagawa, Processing of the Hard to Cut Materials and Heat-resistant Alloys for Aircrafts, J. Jpn Soc. Mech. Eng., 2012, 115(1128), p 762–765 (in Japanese)

Daiyamondo Toishi Kenkyu-kai, Ed, Daiyamondo Toishi no Erabikata Tsukaikata, Nikkan Kogyo Shimbun, Ltd., (1988) ISBN4-526 02451-1, p 5, p 84 (in Japanese)

M. Leitner, T. Leitner, A. Schmon, K. Aziz, and G. Pottlacher, Thermophysical Properties of Liquid Aluminum, Metall. Mater. Trans. A, 2017, 48(6), p 3036–3045

Acknowledgments

This work was supported by The Light Metal Educational Foundation Inc. of Japan. Part of this research was also supported by the Japan Science and Technology Agency (JST) under the Industry-Academia Collaborative R&D Program “Heterogeneous Structure Control: Towards Innovative Development of Metallic Structural Materials.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Watanabe, Y., Sugiura, T., Sato, H. et al. Fabrication of Al-Based Composites by Centrifugal Mixed-Powder Method and Their Application for Grinding Wheels. J. of Materi Eng and Perform 28, 3852–3863 (2019). https://doi.org/10.1007/s11665-019-03917-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03917-3