Abstract

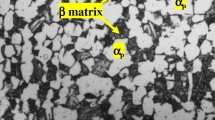

To investigate the tensile deformation behavior of TC21 titanium alloy wires, the isothermal tensile deformation tests were conducted by a Geeble-1500D simulator in the temperature range of 720-880 °C and strain rates of 0.01-10 s−1. The in situ tensile deformation behavior has been studied by SEM SURPA40. The stress–strain curves indicate that the flow stress has shown an inverse relationship with temperature and a direct relationship with strain rate. The flow stress immediately reached the peak value and, then, gradually decreased due to the dynamic softening induced by dynamic recovery and dynamic recrystallization. According to the hot processing maps, the temperatures ranging from 720 to 760 °C (corresponding to the strain rates of 0.01-0.032 s−1) and 800-840 °C (corresponding to the strain rates of 0.01-0.056 s−1) are suitable for processing. The in situ tensile results reveal that the cracks initiated at the pre-fabricated defects with the concentrated stress and mainly propagated in the transgranular mode.

Similar content being viewed by others

References

Z. Wyatt and S. Ankem, The Effect of Metastability on Room Temperature Deformation Behavior of Beta and Alpha Plus Beta Titanium Alloys, J. Mater. Sci., 2010, 45, p 5022–5031

L.I. Xin, L.U. Shiqiang, W.A.N.G. Kelu, Z.H.A.O. Weigang, and L.I. Zhenxi, Optimizing High Temperature Deformation Thermomechanical Parameters of TC11 Titanium Alloy by Means of Murty Criterion, Acta Metall. Sin., 2007, 12, p 1268–1274 (in Chinese)

Q. Henglei, Z. Yongqing, Z. Gang, A kind of high strength and toughness titanium alloy and its processing method, China National Defense Patent., 2003 (in Chinese)

Y.C. Lin, X.Y. Jiang, C.J. Shuai, C.Y. Zhao, and D.G. He, Effects of Initial Microstructures on Hot Tensile Deformation Behaviors and Fracture Characteristics of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2018, 711, p 293–302

W.S. Lee, C.F. Lin, T.H. Chen, and H.H. Hwang, Effects of Strain Rate and Temperature on Mechanical Behaviour of Ti-15Mo-5Zr-3Al Alloy, J. Mech. Behav. Biomed. Mater., 2008, 1, p 336–344

Y.-Q. Jiang, Y.C. Lin, X.-Y. Zhang, C. Chen, Q.-W. Wang, and G.-D. Pang, Isothermal Tensile Deformation Behaviors and Fracture Mechanism of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy in β Phase Field, Vacuum., 2018, 156, p 187–197

Z.H.U. Zhishou, W.A.N.G. Xinnan, G.U. Wei, and C.H.E.N. Minghe, Study on High Temperature Deformation Behaviors of New Type TC21 Titanium Alloy, Mater China, 2009, 28, p 51–55 (in Chinese)

F. Feng, W. Zeng, Y. Zhu, Y. Zhao, and Y. Zhou, Hot Deformation Behavior and Processing Map of As-Cast TC21 Alloy, Rare Met. Mater. Eng., 2012, 41, p 251–255 (in Chinese)

J. Zhao, S. Zhang, M. Cheng, and H. Song, Deformation Behaviors and Microstructure Evolution of TC21 Alloy in Hot Working, Rare Met., 2009, 33, p 153–158

Hui Shao and Di Shan, Accordance Between Fracture Toughness and Strength Difference in TC21 Titanium Alloy with Equiaxed Microstructure, Mater. Sci. Eng. A, 2016, 664, p 10–16

Liu Changxu and Wu Guoqing, Situ Observations of Structural Transformation in TB5 Titanium Alloy During One Way Tensile Test, J. Beijing Univ. Aeronaut. Astronaut., 2012, 38, p 1474–1477 (in Chinese)

Lu Jue, Yanli Song, Lin Hua, Kailun Zheng, and Dingguo Dai, Thermal Deformation Behavior and Processing Maps of 7075 Aluminum Alloy Sheet Based on Isothermal Uniaxial Tensile Tests, J. Alloys Compd., 2018, 767, p 856–869

C. Shi, J. Lai, and X.G. Chen, Microstructural Evolution and Dynamic Softening Mechanisms of Al-Zn-Mg-Cu Alloy During Hot Compressive Deformation, Materials, 2014, 7, p 855–862

L. Feng, Q.U. Heng-Lei, Y.Q. Zhao, L.I. Hui, and Y.N. Zhang, High Temperature Deformation Behavior of TC21 Alloy, j. Aeronaut. Mater., 2004, 2004(24), p 11–13 (in Chinese)

K.P. Rao and Y.V.R.K. Prasad, High Temperature Deformation Kinetics of Al-4Mg Alloy, J. Mech. Sci. Technol., 1986, 13, p 83–89

H. Shi, A.J. Mclaren, and C.M. Swllars, Constitutive Equations for High Temperature Flow Stress of Aluminum Alloys, Mater. Sci. Eng. A., 1997, 13, p 210–216

C.M. Sellars and W.J. Mctegart, On the Mechnism of Hot Deformation, Acta Metall. Sin., 1966, 14, p 1136

J. Luo, M. Li, W. Yu, and H. Li, The Variation of Strain Rate Sensitivity Exponent and Strain Hardening Exponent in Isothermal Compression of Ti-6Al-4V Alloy, Mater. Des., 2010, 31, p 741–748

J.X. Liu, Y.L. Lu, X.K. Li, Z.J. Li, and X.T. Zhou, Constitutive Equation of Hot Tensile Deformation for C276 Super Alloy, J. Plast. Eng., 2012, 19, p 11–15 (in Chinese)

Y.V.R.K. Prasad, D.H. Sastry, and S.C. Deevi, Processing Maps for Hot Working of a P/M Iron Aluminide Alloy, Intermetallics, 2008, 10, p 1067–1074

Y.C. Lin, L. Li, D.G. He, M.S. Chen, and G.Q. Liu, Effects of Pre-treatments on Mechanical Properties and Fracture Mechanism of a Nickel-Based Superalloy, Mater. Sci. Eng. A, 2017, 679, p 401–409

K. Chen, S. Pan, Y. Zhu, Y. Cheng, X. Chen, and Z. Wang, In Situ Observations of Crack Propagation in As-Cast Cu-1.5Fe-0.5Co (wt.%) Alloy, Mater. Sci. Eng. A, 2017, 706, p 211–216

Peng Meiqi, Cheng Xingwang, Zheng Chao, Yang Kaiwen, and Jin Dan, Effects of Secondary α Phase Width on Dynamic Mechanical Properties and Sensitivity of Adiabatic Shear Banding in Bimodal Microstructures of TC4 Alloy, Rare Met. Mater. Eng., 2017, 46, p 1843–1849 (in Chinese)

Guo Ping, Zhao Yongqing, and Zeng Weidong, Fatigue Crack Propagation Rate of Lamellar Microstructure for TC4-DT Titanium Alloy, Rare Met. Mater. Eng., 2016, 45, p 2937–2941

W.E.I. Song-bo, C.A.I. Qing-wu, T.A.N.G. Di, M.E.N.G. Qiang, and L.I. Zhen, In Situ SEM Study of Dynamic Tensile in Wrought Magnesium Alloy AZ31B Rolling Sheet, J. Plast. Eng., 2009, 16, p 155–160

Acknowledgments

This work was supported by Guizhou science and technology fund project (Contract Number [2018]1027); Engineering research center project from Guizhou provincial education department (Contract Number [2017]016); Guizhou major special projects (Contract Number [2014]6013); Science and technology talent growth project from Guizhou provincial education department (Contract Number [2017]238).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, S., Liang, Y., Xia, Q. et al. Study on Tensile Deformation Behavior of TC21 Titanium Alloy. J. of Materi Eng and Perform 28, 1581–1590 (2019). https://doi.org/10.1007/s11665-019-03901-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03901-x