Abstract

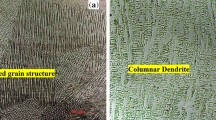

The purpose of this research was to evaluate integrity and microstructure changes of the electron beam-welded Nimonic 80A and the base metal after aging heat treatment process, i.e., 700 °C/72 h/air cooling. Here, microstructure, microhardness and tensile were investigated by various tools, i.e., scanning electron microscope with energy-dispersive spectroscopy and electron backscatter diffraction, x-ray diffraction analysis and Vickers hardness. Evaluation of microstructure shows that the weld zone mainly consists of columnar dendrites. The effect of aging heat treatment on the microstructure morphology and phase structure is very limited. Also, it was observed that there are obvious segregation and precipitates in intracrystalline and along the grain boundaries after aging heat treatment. Electron backscatter diffraction results show that the weld zone and base metal have a clear difference in the grain boundary characterization and kernel average misorientation at room temperature and after aging heat treatment, which leads to a difference in microhardness of the weld zone. In addition, the relationship between microhardness and tensile strength is discussed.

Similar content being viewed by others

References

Z. Liu and X. Xie, 21—The Chinese 700 °C A-USC Development Program A2—Gianfrancesco, Augusto Di, Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plantsed., Woodhead Publishing, 2017, p 715–731

H. Nomoto, 12—Development in Materials for Ultra-Supercritical (USC) and Advanced Ultra-Supercritical (A-USC) Steam Turbines A2—Tanuma, Tadashi, Advances in Steam Turbines for Modern Power Plantsed., Woodhead Publishing, 2017, p 263–278

M. Karadge, M. Preuss, P.J. Withers, and S. Bray, Importance of Crystal Orientation in Linear Friction Joining of Single Crystal to Polycrystalline Nickel-Based Superalloys, Mater. Sci. Eng. A, 2008, 491(1), p 446–453

A. Chamanfar, M. Jahazi, J. Gholipour, P. Wanjara, and S. Yue, Maximizing the Integrity of Linear Friction Welded Waspaloy, Mater. Sci. Eng. A, 2012, 555, p 117–130

M.S. Węglowski, S. Błacha, and A. Phillips, Electron Beam Welding—Techniques and Trends—Review, Vacuum, 2016, 130, p 72–92

J. Liu, X.-L. Gao, L.-J. Zhang, and J.-X. Zhang, Effects of the Heterogeneity in the Electron Beam Welded Joint on Mechanical Properties of Ti6Al4 V Alloy, J. Mater. Eng. Perform., 2015, 24(1), p 319–328

Z. Hong, L. Jiukai, L. Yongjie, and W. Qingyuan, Research on Rotary Bending High Cycle Fatigue Behavior of the Electron Beam Welding Joint for GH80A Nickel Alloy, Adv. Eng. Sci., 2017, 49(4), p 188–195

H. Zhang, C. Huang, Z. Guan, J. Li, Y. Liu, R. Chen, and Q. Wang, Effects of the Electron Beam Welding Process on the Microstructure, Tensile, Fatigue and Fracture Properties of Nickel Alloy Nimonic 80A, J. Mater. Eng. Perform., 2018, 27(1), p 89–98

A. Bonakdar, M. Molavi-Zarandi, A. Chamanfar, M. Jahazi, A. Firoozrai, and E. Morin, Finite Element Modeling of the Electron Beam Welding of Inconel-713LC Gas Turbine Blades, J. Manuf. Process., 2017, 26, p 339–354

Ö. Özgün, R. Yılmaz, H.Ö. Gülsoy, and F. Fındık, The Effect of Aging Treatment on the Fracture Toughness and Impact Strength of Injection Molded Ni-625 Superalloy Parts, Mater. Charact., 2015, 108, p 8–15

E.W. Ross and C.T. Sims, Superalloys-II, Wiley, New York, 1987, p 97–133

S. Mironov, Y.S. Sato, and H. Kokawa, Electron Backscatter Diffraction in Materials Science, Kluwer Academic, New York, 2000

ISO 6507-1:2005 Metallic materials—Vickers hardness test—Part 1: Test method, International Organization for Standardization 2005

ESI Sysweld—Welding, Assembly and Heat Treatment Predictive Simulation (2017), https://www.esi-group.com/software-solutions/virtual-manufacturing/welding-assembly/esi-sysweld

China areonautical materials handbook (Second Volume) Wrought superalloy and Cast superalloy, China Standard Press (2002)

JMatPro (2017), http://www.sentesoftware.co.uk/jmatpro.aspx

J.N. DuPont, J.C. Lippold, and S.D. Kiser, Welding Metallurgy and Weldability of Nickel-base Alloys, Wiley, New York, 2009

S. Kou, Welding Metallurgy, 2nd ed., Wiley, New York, 2002

Y. Xu, C. Yang, Q. Ran, P. Hu, X. Xiao, X. Cao, and G. Jia, Microstructure Evolution and Stress-Rupture Properties of Nimonic 80A After Various Heat Treatments, Mater. Des., 2013, 47(Supplement C), p 218–226

M. Winning and A.D. Rollett, Transition Between Low and High Angle Grain Boundaries, Acta Mater., 2005, 53(10), p 2901–2907

C.A. Schuh, M. Kumar, and W.E. King, Analysis of Grain Boundary Networks and Their Evolution During Grain Boundary Engineering, Acta Mater., 2003, 51(3), p 687–700

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Formation of Annealing Twins in f.c.c. Crystals, Acta Mater., 1997, 45(6), p 2633–2638

S.I. Wright, M.M. Nowell, and D.P. Field, A Review of Strain Analysis Using Electron Backscatter Diffraction, Microsc. Microanal., 2011, 17(3), p 316

J.D. Santos, G. Çam, F. Torster, A. Insfran, S. Riekehr, V. Ventzke, and M. Koçak, Properties of Power Beam Welded Steels, Al-and Ti-Alloys: Significance of Strength Mismatch, Weld. World, 2000, 44, p 42–64

H. Zhang, Y. Zhang, L. Li, and X. Ma, Influence of Weld Mis-Matching on Fatigue Crack Growth Behaviors of Electron Beam Welded Joints, Mater. Sci. Eng. A, 2002, 334(1–2), p 141–146

C.J. Parga, I.J. van Rooyen, B.D. Coryell, W.R. Lloyd, L.N. Valenti, and H. Usman, Room Temperature Mechanical Properties of Electron Beam Welded Zircaloy-4 Sheet, J. Mater. Process. Technol., 2017, 241, p 73–85

J.R. Cahoon, An Improved Equation Relating Hardness to Ultimate Strength, Metall. Trans., 1972, 3(11), p 3040

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, The Determination of Yield Strength from Hardness Measurements, Metall. Trans., 1971, 2(7), p 1979–1983

J. Moteff, R.K. Bhargava, and W.L. McCullough, Correlation of the Hot-Hardness with the Tensile Strength of 304 Stainless Steel to Temperatures of 1200 °C, MTA, 1975, 6(5), p 1101

C. Stocker, M. Zimmermann, and H.J. Christ, Effect of Precipitation Condition, Prestrain and Temperature on the Fatigue Behaviour of Wrought Nickel-Based Superalloys in the VHCF Range, Acta Mater., 2011, 59(13), p 5288–5304

Acknowledgments

This work was supported by the National Natural Science Research Foundation of China (11327801, 11502151, 11772209 and 11572057), the Program for Changjiang Scholars and Innovative Research Team (IRT14R37), the Key Science and Technology Support Program of Sichuan Province (2015JPT0001) and supported by the fund of State Key Laboratory of Long-life High Temperature Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Li, P., Wang, Q. et al. Electron Beam Welding of Nimonic 80A Superalloy: Microstructure Evolution and EBSD Study After Aging Heat Treatment. J. of Materi Eng and Perform 28, 741–752 (2019). https://doi.org/10.1007/s11665-018-3817-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3817-5