Abstract

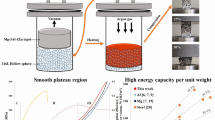

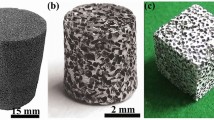

In the present work, cylindrical shape 316 L cellular structure with different densities in its core and outer layer (shell) is fabricated by using carbamide as a space holder, via powder metallurgy route and layer-by-layer technique. The arrangement of the created pore is the same as face-centered cubic atomic structure, and different densities are created in two regions by using carbamide particles having two different sizes in the range of 1.7-2 and 2-2.4 mm. The effect of creating a structure with higher porosity (64.5%) in the core and lower porosity (53.8%) in the shell and vice versa and also change in the ratio of the core to the cylinder cross-sectional areas, on the mechanical properties and compaction load bearing of the fabricated foam samples were investigated. In leaching process of the carbamide particles, as an important step of porous structure’s fabrication, it is shown that discontinuous leaching process is more favorable than continuous, by which it would be possible to remove more carbamide particles (around 20%) at the same time. Furthermore, the deformation of the density-graded foam shows the parallel mechanism in the core and shell sections, and the contribution of each part depends on its density and thickness. The energy absorption behavior of the fabricated specimens is evaluated optimally in terms of the energy absorption value associated with the ideal adsorption behavior. The maximum ideal energy absorption efficiency for the samples with more porosity in the shell was approximately equal to 0.91, while for the sample includes the lower amount of porosity in the shell, this value was in the range of 0.85 and 0.89.

Similar content being viewed by others

References

J. Weise, D. Lehmhus, J. Baumeister, R. Kun, M. Bayoumi, and M. Busse, Production and Properties of 316l Stainless Steel Cellular Materials and Syntactic Foams, Steel Res. Int., 2014, 85(3), p 486–497

I. Mutlu and E. Oktay, Production and Aging of Highly Porous 17-4 PH Stainless Steel, J. Porous Mater., 2012, 19(4), p 433–440

H.Ö. Gülsoy and R.M. German, Sintered Foams from Precipitation Hardened Stainless Steel Powder, Powder Metall., 2008, 51(4), p 350–353. https://doi.org/10.1179/174329008X286703

D.P. Mondal, H. Jain, S. Das, and A.K. Jha, Stainless Steel Foams Made through Powder Metallurgy Route Using NH4HCO3 as Space Holder, Mater. Des., 2015, 88, p 430–437. https://doi.org/10.1016/j.matdes.2015.09.020

S.V. Raj and L.J. Ghosn, Failure Maps for Rectangular 17-4PH Stainless Steel Sandwiched Foam Panels, Mater. Sci. Eng. A, 2008, 474(1-2), p 88–95

I. Mutlu and E. Oktay, Characterization of 17-4 PH Stainless Steel Foam for Biomedical Applications in Simulated Body Fluid and Artificial Saliva Environments, Mater. Sci. Eng. C. Mater. Biol. Appl., 2013, 33(3), p 1125–1131. https://doi.org/10.1016/j.msec.2012.12.004

D.R. Tian, Y.H. Pang, L. Yu, and L. Sun, Production and Characterization of High Porosity Porous Fe-Cr-C Alloys by the Space Holder Leaching Technique, Int. J. Miner. Metall. Mater., 2016, 23(7), p 793–798. https://doi.org/10.1007/s12613-016-1293-1

I. Mutlu and E. Oktay, Mechanical Properties of Sinter-Hardened Cr-Si-Ni-Mo Based Steel Foam, Mater. Des., 2013, 44, p 274–282. https://doi.org/10.1016/j.matdes.2012.08.032

A.K. Barnwal, D.P. Mondal, R. Kumar, N. Prasanth, and R. Dasgupta, Compressive Deformation Behavior of Open-Cell Cu-Zn-Al Alloy Foam Made Through P/M Route Using Mechanically Alloyed Powder, J. Mater. Eng. Perform., 2018, https://doi.org/10.1007/s11665-018-3165-5

A. Mansourighasri, N. Muhamad, and A.B. Sulong, Processing Titanium Foams Using Tapioca Starch as a Space Holder, J. Mater. Process. Technol., 2012, 212(1), p 83–89. https://doi.org/10.1016/j.jmatprotec.2011.08.008

B. Xie, Y.Z. Fan, T.Z. Mu, and B. Deng, Fabrication and Energy Absorption Properties of Titanium Foam with CaCl 2 as a Space Holder, Mater. Sci. Eng. A, 2017, 708(13-16), p 419–423. https://doi.org/10.1016/j.msea.2017.09.123

A. Hassani, A. Habibolahzadeh, and H. Bafti, Production of Graded Aluminum Foams via Powder Space Holder Technique, Mater. Des., 2012, 40, p 510–515. https://doi.org/10.1016/j.matdes.2012.04.024

H. Bafti and A. Habibolahzadeh, Production of Aluminum Foam by Spherical Carbamide Space Holder Technique-Processing Parameters, Mater. Des., 2010, 31(9), p 4122–4129

N. Bekoz and E. Oktay, Effects of Carbamide Shape and Content on Processing and Properties of Steel Foams, J. Mater. Process. Technol., 2012, 212(10), p 2109–2116. https://doi.org/10.1016/j.jmatprotec.2012.05.015

A.H. Brothers and D.C. Dunand, Density-Graded Cellular Aluminum, Adv. Eng. Mater., 2006, 8(9), p 805–809

Y. Hangai, K. Takahashi, T. Utsunomiya, S. Kitahara, O. Kuwazuru, and N. Yoshikawa, Fabrication of Functionally Graded Aluminum Foam Using Aluminum Alloy Die Castings by Friction Stir Processing, Mater. Sci. Eng. A, 2012, 534, p 716–719. https://doi.org/10.1016/j.msea.2011.11.100

Y. Hangai, T. Morita, S. Koyama, O. Kuwazuru, and N. Yoshikawa, Functionally Graded Aluminum Foam Fabricated by Friction Powder Sintering Process with Traversing Tool, J. Mater. Eng. Perform., 2016, 25(9), p 3691–3696

Y. Hangai, K. Saito, T. Utsunomiya, O. Kuwazuru, and N. Yoshikawa, Fabrication and Compression Properties of Functionally Graded Foam with Uniform Pore Structures Consisting of Dissimilar A1050 and A6061 Aluminum Alloys, Mater. Sci. Eng. A, 2014, 613, p 163–170. https://doi.org/10.1016/j.msea.2014.06.039

G. Sun, G. Li, S. Hou, S. Zhou, W. Li, and Q. Li, Crashworthiness Design for Functionally Graded Foam-Filled Thin-Walled Structures, Mater. Sci. Eng. A, 2010, 527(7-8), p 1911–1919. https://doi.org/10.1016/j.msea.2009.11.022

J. Fang, Y. Gao, X. An, G. Sun, J. Chen, and Q. Li, Design of Transversely-Graded Foam and Wall Thickness Structures for Crashworthiness Criteria, Compos. Part B Eng., 2016, 92, p 338–349

Y. Torres, P. Trueba, J.J. Pavón, E. Chicardi, P. Kamm, F. García-Moreno, and J.A. Rodríguez-Ortiz, Design, Processing and Characterization of Titanium with Radial Graded Porosity for Bone Implants, Mater. Des., 2016, 110, p 179–187. https://doi.org/10.1016/j.matdes.2016.07.135

M. Mirzaei and M.H. Paydar, A Novel Process for Manufacturing Porous 316 L Stainless Steel with Uniform Pore Distribution, Mater. Des., 2017, 121, p 442–449. https://doi.org/10.1016/j.matdes.2017.02.069

S.H. Yalkowsky, Y. He, and P. Jain, Handbook of Aqueous Solubility Data, 2nd ed., CRC Press, Boca Raton, 2010

M. Koebel and E.O. Strutz, Thermal and Hydrolytic Decomposition of Urea for Automotive Selective Catalytic Reduction Systems: Thermochemical and Practical Aspects, Ind. Eng. Chem. Res., 2003, 42(10), p 2093–2100. https://doi.org/10.1021/ie020950o

Y. Mu and G. Yao, Anisotropic Compressive Behavior of Closed-Cell Al-Si Alloy Foams, Mater. Sci. Eng. A, 2010, 527(4-5), p 1117–1119. https://doi.org/10.1016/j.msea.2009.09.045

G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, Handbook of Workability and Process Design, ASM international, Materials Park, 2003

Y. Hangai, R. Yamaguchi, S. Takahashi, T. Utsunomiya, O. Kuwazuru, and N. Yoshikawa, Deformation Behavior Estimation of Aluminum Foam by X-Ray CT Image-Based Finite Element Analysis, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2013, 44(4), p 1880–1886

M.S.S. Attia, S.A.A. Meguid, and H. Nouraei, Nonlinear Finite Element Analysis of the Crush Behaviour of Functionally Graded Foam-Filled Columns, Finite Elem. Anal. Des., 2012, 61, p 50–59. https://doi.org/10.1016/j.finel.2012.06.004

J. Miltz and O. Ramon, Energy Absorption Characteristics of Polymeric Foams Used as Cushioning Materials, Polym. Eng. Sci., 1990, 30(2), p 129–133. https://doi.org/10.1002/pen.760300210

M. Avalle, G. Belingardi, and A. Ibba, Mechanical Models of Cellular Solids: Parameters Identification from Experimental Tests, Int. J. Impact Eng., 2007, 34(1), p 3–27

M. Avalle, G. Belingardi, and R. Montanini, Characterization of Polymeric Structural Foams under Compressive Impact Loading by Means of Energy-Absorption Diagram, Int. J. Impact Eng., 2001, 25(5), p 455–472

Acknowledgment

This work was financially supported partly by Shiraz University under the Grant No. of Eng. 95GRD1M1818.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirzaei, M., Paydar, M.H. Fabrication and Characterization of Core–Shell Density-Graded 316L Stainless Steel Porous Structure. J. of Materi Eng and Perform 28, 221–230 (2019). https://doi.org/10.1007/s11665-018-3797-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3797-5