Abstract

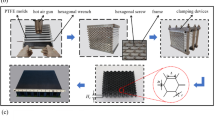

In this study, positive-pressure, bending, and drum peel tests were carried out for aluminum honeycomb sandwich panels made of different materials and with different dimensions. The results of these tests not only precisely revealed the relationships between the mechanical properties of aluminum honeycomb sandwich panels and the material dimensions of the face and core layers, the layout mode of the core layer, and the connecting mode between the face layers and core layers, but also determined the reliable mechanical equivalent model. The test results indicate that when the specimen was subjected to the vertical load, the compression properties of aluminum honeycomb sandwich panels were mainly determined by its core layer, while the face layer mainly relieves the axial stress and restrains the deformation of the core layer. In the flexural test, the face layer is the main part subjected to the load, whereas the core layer shows supporting, stabilizing, and strengthening effects, slowing the deformation of the face layer; flexural-tensile properties can be somewhat affected by the layout type of the core layer. The equivalent plate model, honeycomb plate model, and sandwich panel model were screened based on the experimental results, indicating that the sandwich panel model provided a more accurate description. The sandwich panel model was further modified, ultimately resulting in a more effective equivalent model that can accurately reflect the mechanical properties of the aluminum honeycomb sandwich panels.

Similar content being viewed by others

References

X. Li, P. Zhang, Z. Wang et al., Dynamic Behavior Of Aluminum Honeycomb Sandwich Panels Under Air Blast: Experiment and Numerical Analysis, Compos. Struct., 2014, 108, p 1001–1008

S. Ai, Y. Mao, Y. Pei et al., Study on Aluminum Honeycomb Sandwich Panels with Random Skin/Core Weld Defects, J. Sandwich Struct. Mater., 2013, 15(6), p 704–717

Zhou Zhulin, Ultimate Strength of Sandwich Panels With Honeycomb Core, Chin. J. Theor. Appl. Mech, 1983, 01, p 62–69

Wu Pan Shidong and Sun Yuguo Linzhi, Transverse Shear Modulus and Strength of Honeycomb Cores, Compos. Struct., 2008, 84(4), p 369–374

Y. Chi, G.S. Langdon, and G.N. Nurick, The Influence of Core Height and Face Plate Thickness on the Response of Honeycomb Sandwich Panels Subjected to Blast Loading, Mater. Des., 2010, 31, p 1887–1899

Shaw M. Lee and Thomas K. Tsotsis, Indentation Failure Behavior of Honeycomb Sandwich Panels, Compos. Sci. Technol, 2000, 60, p 1147–1159

J. Oltmann, R. Seemann, D. Krause, Experimental investigation on damping for honeycomb sandwich panels under different support conditions, in 5th International Workshop on Aircraft System Technologies (AST), Hamburg, pp. 207–216 (2015)

X. Li, Z. Wang, F. Zhu et al., Response of Aluminium Corrugated Sandwich Panels Under Air Blast Loadings: Experiment and Numerical Simulation, Int. J. Impact Eng, 2014, 65, p 79–88

H.N.G. Wadley, T. Børvik, L. Olovsson et al., Deformation and Fracture of Impulsively Loaded Sandwich Panels, J. Mech. Phys. Solids, 2013, 61(2), p 674–699

H.S. Kim and S.T.S. Al-Hassani, A Morphological Elastic Model of General Hexagonal Columnar Structures, Int. J. Mech. Sci., 2001, 43, p 1027–1060

I.G. Master and K.E. Evans, Models for the Elastic Deformation of Honeycombs, Compos. Struct., 1996, 35, p 403–422

L.J. Gibson, M.F. Ashby, and G.S. Schajer, The Mechanics of Two-dimensional Cellular Materials, Proc R Soc Lond (A), 1982, 382, p 25–42

M.J. Silva, W.C. Hayes, and L.J. Gibson, The Effect of Non-periodic Microstructure on the Elastic Properties of Two-dimensional Cellular Solids, Int. J. Mech. Sci., 1995, 37, p 1161–1177

Xia Lijuan and Jin Xianding, Equivalent Analysis of Honeycomb Sandwich Plates for Satellite Structure, J. Shanghai Jiaotong Univ., 2003, 37(7), p 999–1001

GBT 1453-2005, Test Method for Flatwise Compression Properties of Sandwich Constructions Or Cores, 2005

GBT 1456-2005, Test Method for Flexural Properties of Sandwich Constructions, 2005

GBT 1457-2005, Test method for Climbing Drum Peel Strength of Sandwich Constructions, 2005

X. Guojun, Test and Research of a New-Style Honeycomb Structure Floor Used on Dry Cargo Container, South China University of Technology, Guangzhou, 2012

Kou Dongpeng, Effect of Randomly Cell Walls on the Dynamic Crushing Behaviour of Honeycomb Structures, Chin. J. Theor. Appl. Mech., 2009, 06, p 859–868

K. Li, X.L. Gao, and J. Wang, Dynamic Crushing Behavior of Honeycomb Structures with Irregular Cell Shapes and Non-uniform Cell Wall Thickness, Int. J. Solids Struct., 2007, 44(14), p 5003–5026

Zhang Tieliang and Ding Yunliang, Comparative Analysis of Equivalent Models for Honeycomb Sandwich Plates, Chin. J. Appl. Mech., 2011, 28(3), p 275–282

United States Department of Defense, Structural sandwich composites, Department of Defense, Washington DC, 1968

Shaohui Zhou, Study on Design Method for Pavement structure of Aluminum Honeycomb Assembled Pavement Panel, Air Force Engineering University, Xi’an, 2014

Yuan Aimin, Studies on Several Key Problems of Finite Element Model Updating Based on the Sensitivity Analysis, Southeast University, Nanjing, 2006

Funding

This study was funded by the National Natural Science Fund (Grant Number 51578540).

Conflict of InterestThe authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, L., Zhang, D., Zhou, S. et al. Investigation on Mechanical Properties and Equivalent Model of Aluminum Honeycomb Sandwich Panels. J. of Materi Eng and Perform 27, 6585–6596 (2018). https://doi.org/10.1007/s11665-018-3771-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3771-2