Abstract

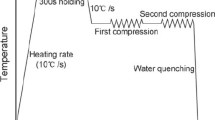

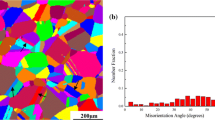

In order to clarify the microstructure evolution characteristics during holding period after slight degree of deformation for a Ni-Cr-Mo-based C276 superalloy, two-stage isothermal compression tests have been performed at the temperature range of 1000-1150 °C and the strain rate range of 0.1-5 s−1. The stress–strain curves and microstructure observation infer that both static recovery (SRV) and static recrystallization (SRX) took place during the holding period when the specimens were deformed at 1100-1150 °C and only SRV occurred in the specimens that deformed at the temperatures lower than 1100 °C. The softening effects increase with the increasing temperature and deformation degree, while the influence of strain rate seems less pronounced because of the limited stored energy resulted from the small deformation. The grain boundary characteristics, analyzed using electron backscatter diffraction technique, indicate that high densities of twins and \(\varSigma 3\) grain boundaries form associated with the nucleation and growth of SRX grains. Finally, the recrystallization during and after deformation, i.e., dynamic recrystallization, SRX and metadynamic recrystallization, was discussed concurrently.

Similar content being viewed by others

References

J.S. Tiley, D.W. Mahaffey, T. Alam, T. Rojhirunsakool, O. Senkov, T. Parthasarthy, and R. Banerjee, Strengthening Mechanisms in an Inertia Friction Welded Nickel-Base Superalloy, Mater. Sci. Eng. A, 2016, 662, p 26–35

N. Souaï, N. Bozzolo, L. Nazé, Y. Chastel, and R. Logé, About the Possibility of Grain Boundary Engineering Via Hot-Working in a Nickel-Base Superalloy, Scripta Mater., 2010, 62(11), p 851–854

R.J. Lancaster, M.T. Whittaker, S.J. Williams. A Review of Thermo-Mechanical Fatigue Behaviour in Polycrystalline Nickel Superalloys for Turbine Disc Applications, 1st edn (Science Reviews 2000 Ltd; 2013), pp. 2–12.

J. Guo, Review on Wrought Superalloy and Equiaxed Crystal Cast Superalloy Materials and Their Application Basic Theories, Jinshu Xuebao/Acta Metallurgica Sinica, 2010, 46(11), p 1303–1321

G.-Z. Quan, J. Pan, X. Wang, Z.-H. Zhang, L. Zhang, and T. Wang, Correspondence Between Grain Refinements And Flow Softening Behaviors at Nimonic 80A Superalloy Under Different Strain Rates, Temperatures and Strains, Mater. Sci. Eng. A, 2017, 679, p 358–371

Y. Liu, Z. Yao, Y. Ning, and Y. Nan, Effect of Deformation Temperature and Strain Rate on Dynamic Recrystallized Grain Size of a Powder Metallurgical Nickel-Based Superalloy, J. Alloy. Compd., 2017, 691, p 554–563

S.S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah, Strain Rate Dependent Microstructural Evolution During Hot Deformation of a Hot Isostatically Processed Nickel Base Superalloy, J. Alloy. Compd., 2016, 681, p 28–42

S. Gardner, W. Li, M. Coleman, and R. Johnston, The Effects Of Thermomechanical History on the Microstructure of a Nickel-Base Superalloy During Forging, Mater. Sci. Eng. A, 2016, 668, p 263–270

Q.Y. Yu, Z.H. Yao, and J.X. Dong, Deformation and Recrystallization Behavior of a Coarse-Grain, Nickel-Base Superalloy Udimet720Li Ingot Material, Mater. Charact., 2015, 107, p 398–410

X.-M. Chen, Y.C. Lin, M.-S. Chen, H.-B. Li, D.-X. Wen, J.-L. Zhang, and M. He, Microstructural Evolution of a Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2015, 77, p 41–49

M. Aghaie-Khafri and N. Golarzi, Forming Behavior and Workability of Hastelloy X Superalloy During Hot Deformation, Mater. Sci. Eng. A, 2008, 486(1–2), p 641–647

F. Tancret, E. Galindo-Nava, and P.E.J. Rivera Díaz-del-Castillo, Dynamic Recrystallisation Model in Precipitation-Hardened Superalloys as a Tool for the Joint Design of Alloys and Forming Processes, Mater. Des., 2016, 103, p 293–299

D.-X. Wen, Y.C. Lin, and Y. Zhou, A New Dynamic Recrystallization Kinetics Model for a Nb Containing Ni-Fe-Cr-base Superalloy Considering Influences of Initial Phase, Vacuum, 2017, 141, p 316–327

Y.-X. Liu, Y.C. Lin, and Y. Zhou, 2D Cellular Automaton Simulation of Hot Deformation Behavior in a Ni-Based Superalloy Under Varying Thermal-Mechanical Conditions, Mater. Sci. Eng. A, 2017, 691, p 88–99

D.-D. Chen, Y.C. Lin, Y. Zhou, M.-S. Chen, and D.-X. Wen, Dislocation Substructures Evolution and an Adaptive-Network-Based Fuzzy Inference System Model for Constitutive Behavior of a Ni-Based Superalloy During Hot Deformation, J. Alloy. Compd., 2017, 708, p 938–946

N. Wanderka, A. Bakai, C. Abromeit, D. Isheim, and D.N. Seidman, Effects of 10 MeV Electron Irradiation at High Temperature of a Ni-Mo-Based Hastelloy, Ultramicroscopy, 2007, 107(9), p 786–790

Y.Q. Guo, D.J. Wu, G.Y. Ma, and D.M. Guo, Trailing Heat Sink Effects on Residual Stress and Distortion of Pulsed Laser Welded Hastelloy C-276 Thin Sheets, J. Mater. Process. Technol., 2014, 214(12), p 2891–2899

R. Li, C. Zhang, L. Zhang, Y. Cui, and W. Shen, Expanding the Applicable Duration for Shrink Fitting of the Ultrathin-Walled Reactor Coolant Pump Rotor-Can, Ann. Nucl. Energy, 2017, 110, p 1217–1223

V. Randle, Twinning-Related Grain Boundary Engineering, Acta Mater., 2004, 52(14), p 4067–4081

H. Akhiani, M. Nezakat, M. Sanayei, and J. Szpunar, The Effect of Thermo-Mechanical Processing on Grain Boundary Character Distribution in Incoloy 800H/HT, Mater. Sci. Eng. A, 2015, 626, p 51–60

K. Deepak, S. Mandal, C.N. Athreya, D.-I. Kim, B. de Boer, and V. Subramanya Sarma, Implication of Grain Boundary Engineering on High Temperature Hot Corrosion of Alloy 617, Corros. Sci., 2016, 106, p 293–297

W. Cao, S. Xia, Q. Bai, W. Zhang, B. Zhou, Z. Li, and L. Jiang, Effects of Initial Microstructure on the Grain Boundary Network During Grain Boundary Engineering in Hastelloy N Alloy, J. Alloy. Compd., 2017, 704, p 724–733

Y. Cao, H. Di, and G. Huang, On the Grain Boundary Character Distribution of Incoloy 800H During Dynamic Recrystallization, J. Nucl. Mater., 2017, 486, p 21–25

Y. Kong, P. Chang, Q. Li, L. Xie, and S. Zhu, Hot Deformation Characteristics and Processing Map of Nickel-Based C276 Superalloy, J. Alloy. Compd., 2015, 622, p 738–744

C. Zhang, L. Zhang, W. Shen, Q. Xu, and Y. Cui, The Processing Map and Microstructure Evolution of Ni-Cr-Mo-Based C276 Superalloy During Hot Compression, J. Alloy. Compd., 2017, 728, p 1269–1278

Z. Chi, Z. Liwen, S. Wenfei, L. Mengfei, and G. Sendong, Characterization of Hot Deformation Behavior of Hastelloy C-276 Using Constitutive Equation and Processing Map, J. Mater. Eng. Perform., 2015, 24(1), p 149–157

Z. Chi, Z. Liwen, S. Wenfei, L. Cuiru, and G. Sendong, The Kinetics of Metadynamic Recrystallization in a Ni-Cr-Mo-Based Superalloy Hastelloy C-276, J. Mater. Eng. Perform., 2016, 25(2), p 545–552

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater Sci., 2014, 60, p 130–207

X. Tang, B. Wang, H. Ji, X. Fu, and W. Xiao, Behavior and Modeling of Microstructure Evolution During Metadynamic Recrystallization of a Ni-Based Superalloy, Mater. Sci. Eng. A, 2016, 675, p 192–203

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, and R. Srinivasan, Microstructural Modeling of Metadynamic Recrystallization in Hot Working of IN 718 Superalloy, Mater. Sci. Eng. A, 2000, 293(1–2), p 198–207

D.-G. He, Y.C. Lin, M.-S. Chen, and L. Li, Kinetics Equations and Microstructural Evolution During Metadynamic Recrystallization in a Nickel-Based Superalloy with δ Phase, J. Alloy. Compd., 2017, 690, p 971–978

Y. Cheng, H. Du, Y. Wei, L. Hou, and B. Liu, Metadynamic Recrystallization Behavior and Workability Characteristics Of HR3C Austenitic Heat-Resistant Stainless Steel with Processing Map, J. Mater. Process. Technol., 2016, 235, p 134–142

P. Mukhopadhyay, M. Loeck, and G. Gottstein, A Cellular Operator Model for the Simulation of Static Recrystallization, Acta Mater., 2007, 55(2), p 551–564

Y.G. Liu, J. Liu, M.Q. Li, and H. Lin, The Study on Kinetics of Static Recrystallization in the Two-Stage Isothermal Compression of 300M Steel, Comput. Mater. Sci., 2014, 84, p 115–121

A.M. Elwazri, P. Wanjara, and S. Yue, Metadynamic and Static Recrystallization of Hypereutectoid Steel, ISIJ Int., 2003, 43(7), p 1080–1088

Y.C. Lin, Y.-X. Liu, M.-S. Chen, M.-H. Huang, X. Ma, and Z.-L. Long, Study of Static Recrystallization Behavior in Hot Deformed Ni-Based Superalloy Using Cellular Automaton Model, Mater. Des., 2016, 99, p 107–114

A. Laasraoui and J.J. Jonas, Recrystallization of Austenite After Deformation at High Temperatures and Strain Rates—Analysis and Modeling, Metall. Trans. A, 1991, 22A(1), p 151–160

A.M. Elwazri, E. Essadiqi, and S. Yue, Kinetics of Metadynamic Recrystallization in Microalloyed Hypereutectoid Steels, ISIJ Int., 2004, 44(4), p 744–752

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51604058), the Major State Basic Research Development Program of China (973 program) (No. 2015cb057305), the Fundamental Research Funds for the Central Universities of China, the Open Research Fund from the State Key Laboratory of Rolling and Automation, Northeastern University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, L., Cui, Y. et al. Characterization of Static Recrystallization of a Ni-Cr-Mo-Based C276 Superalloy in Two-Stage Isothermal Compression. J. of Materi Eng and Perform 27, 6426–6434 (2018). https://doi.org/10.1007/s11665-018-3761-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3761-4