Abstract

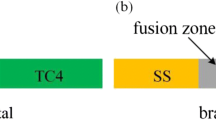

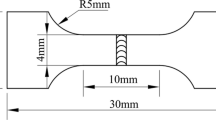

Pulsed laser welding of Ti alloy to stainless steel (SS) has been applied without filler metal. When the laser beam was focused on the Ti alloy–SS interface, large volumes of Ti-Fe intermetallics were formed in the joint. These Ti-Fe intermetallics were highly brittle, causing the joint to crack spontaneously after welding. The brittle coarse Ti-Fe intermetallics seriously deteriorates the joint strength of Ti alloy and SS; therefore, it is necessary to control the quantities and distributions of brittle Ti-Fe intermetallics in the joint. The amount of melted base materials was controlled by changing laser offset to control the melted proportion and thus control the quantity and distribution of brittle Ti-Fe intermetallics in weld. When laser beam was on the SS side, melting amount of Ti alloy in weld was decreased. When laser beam was on the Ti alloy side, melting amount of SS in weld was decreased. When the laser offset was 0.35 mm away from SS side, the sample realizes the effective connection between Ti alloy and SS. A compound layer was formed at the SS side with the main microstructure of β-Ti and TiFe2. The joint fractured at the compound layer with the maximum tensile strength of 182 MPa. Microstructures and mechanical properties of joints were improved by changing laser offset.

Similar content being viewed by others

References

U.K. Mudali, B.M.A. Rao, K. Shanmugam, R. Natarajan, and B. Raj, Corrosion and Microstructural Aspects of Dissimilar Joints of Titanium and Type 304L Stainless Steel, J. Nucl. Mater., 2003, 321(1), p 40–48

M. Ghosh, S. Chatterjee, and B. Mishra, The Effect of Intermetallics on the Strength Properties of Diffusion Bonds Formed Between Ti-5.5Al-2.4V and 304 Stainless Steel, Mater. Sci. Eng. A, 2003, 363(1–2), p 268–274

X.J. Yuan, G.M. Sheng, and B. Qin, Impulse Pressuring Diffusion Bonding of Titanium Alloy to Stainless Steel, Mater. Charact., 2008, 59(7), p 930–936

S. Chen, M. Zhang, J. Huang, C. Cui, H. Zhang, and X. Zhao, Microstructures and Mechanical Property of Laser Butt Welding of Titanium Alloy to Stainless Steel, Mater. Des., 2014, 53, p 504–511

G. Satoh, Y.L. Yao, and C. Qiu, Strength and Microstructure of Laser Fusion-Welded Ti-SS Dissimilar Material Pair, Int. J. Adv. Manuf. Technol., 2013, 66(1–4), p 469–479

J.L. Murray, The Fe-Ti (Iron-Titanium) System, Bull. Alloys Phase Diagr., 1981, 2, p 320–334

S.A.A. Akbari Mousavi and P.F. Sartangi, Effect of Post-weld Heat Treatment on the Interface Microstructure of Explosively Welded Titanium-Stainless Steel Composite, Mater. Sci. Eng., 2008, 494(1–2), p 329–336

S. Kundu, M. Ghosh, A. Laik, K. Bhanumuthy, G.B. Kale, and S. Chatterjee, Diffusion Bonding of Commercially Pure Titanium to 304 Stainless Steel Using Copper Interlayer, Mater. Sci. Eng. A, 2005, 407(1–2), p 154–160

M. Ghosh and S. Chatterjee, Effect of Interface Microstructure on the Bond Strength of the Diffusion Welded Joints Between Titanium and Stainless Steel, Mater. Charact., 2005, 54(4–5), p 327–337

H. Hiraga, K. Fukatsu, K. Ogawa, M. Nakayama, and Y. Muto, Nd:YAG Laser Welding of Pure Titanium to Stainless Steel, Weld. Int., 2002, 16(8), p 623–631

B. Kurta, N. Orhan, E. Evin, and A. Çalik, Diffusion Bonding Between Ti-6Al-4V Alloy and Ferritic Stainless Steel, Mater. Lett., 2007, 61(8–9), p 1747–1750

M. Fazel-Najafabadi, S.F. Kashani-Bozorg, and A. Zarei-Hanzaki, Dissimilar Lap Joining of 304 Stainless Steel to CP-Ti Employing Friction Stir Welding, Mater. Des., 2011, 32(4), p 1824–1832

S.A.A. Mousavi and S.P. Farhadi, Experimental Investigation of Explosive Welding of Co-titanium/AISI, 304 Stainless Steel, Mater. Des., 2009, 30, p 459–468

F. Vollertsen and M. Grupp, Laser Beam Joining of Dissimilar Thin Sheet Materials, Steel Res. Int., 2005, 76, p 240–244

C. Tan, J. Yang, X. Zhao, K. Zhang, X. Song, B. Chen, L. Li, and J. Feng, Influence of Ni Coating on Interfacial Reactions and Mechanical Properties in Laser Welding–Brazing of Mg/Ti Butt Joint, J. Alloys Compd., 2018, 764, p 186–201

S.S. Zhao, G. Yu, X.L. He, Y.J. Zhang, and W.J. Ning, Numerical Simulation and Experimental Investigation of Laser Overlap Welding of Ti6Al4V and 42CrMo, J. Mater. Process. Technol., 2011, 211(3), p 530–537

H.G. Dong, Z.L. Yang, Z.R. Wang, D.W. Deng, and C. Dong, Vacuum Brazing TC4 Ti Alloy to 304 Stainless Steel with Cu-Ti-Ni-Zr-V Amorphous Alloy, JMEPEG, 2014, 23(10), p 3770–3777

H.M. Li, D.Q. Sun, P. Dong, W.Q. Wang, and S.Q. Yin, Study on Laser Welding of Dissimilar Materials Between TiNi Shape Memory Alloy/Stainless Steel, J. Mater. Eng. Perform., 2011, 10(1), p 47–52

X. Hu, W. Y, and Y. Xu, Temperature Field Analysis of Laser Welding of Titanium Steel Dissimilar Material, Automob. Parts, 2016, 1, p 1–6

B. Aleman, I. Gutierrez, and J.J. Urcola, Interface Microstructures in Diffusion Bonding of Titanium Alloys to Stainless Steel and Low Alloy Steels, Mater. Sci. Technol., 1993, 9(8), p 633–641

C. Yao, X. Binshi, X. Zhang, J. Huang, F. Jun, and W. Yixiong, Interface Microstructure and Mechanical Properties of Laser Welding Copper-Steel Dissimilar Joint, Opt. Lasers Eng., 2009, 47(7–8), p 807–814

I. Tomashchuk, P. Sallamand, H. Andrzejewski, and D. Grevey, The Formation of Intermetallics in Dissimilar Ti6Al4V/Copper/AISI, 316L Electron Beam and Nd:YAG Laser Joints, Intermetallics, 2011, 19(10), p 1466–1473

C. Yu, M.F. Wu, and H. Lu, Factors Influencing Formation and Growth of Coarse Ti-Fe Compound in Ti-Fe Eutectic Reaction, Sci. Technol. Weld. Join., 2006, 11(3), p 265–270

Y. Zhang, D. Sun, X.Y. Gu, and Y. Liu, Nd/YAG Pulsed Laser Welding of TC4 Titanium Alloy to 301L Stainless Steel via Pure Copper Interlayer, Int. J. Adv. Manuf. Technol., 2017, 90(1–4), p 953–961

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Sun, DQ., Gu, XY. et al. Microstructure and Mechanical Property Improvement in Laser-Welded TC4 Titanium Alloy and 301L Stainless Steel Joints Without Filler Metal. J. of Materi Eng and Perform 28, 140–153 (2019). https://doi.org/10.1007/s11665-018-3753-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3753-4