Abstract

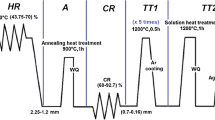

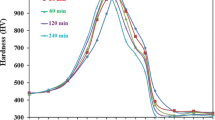

The Fe-32%Ni-4%Co alloy was cryorolled to produce thickness reductions of 10, 40, 60 and 90%; then, the strips with a final thickness of 0.52 mm were annealed at 893, 923 and 943 K for different soaking times. The x-ray diffraction measurements indicated that both thermally induced α′-martensite (α′-M) and deformation-induced α′-M were present in the tested alloy. The thermally induced α′-M was mainly lath-shaped, while the morphology of the deformation-induced α′-M gradually changed from lath-shaped to irregular-shaped according to transmission electron microscopy observations. After the 90% reduction due to cryorolling, the total volume fraction of α′-M reached 75.6%, and the average ultimate tensile strength (UTSav.) was significantly improved from 430.3 to 1306.8 MPa. Upon subsequent annealing at 923 K for 5 min, the tested alloy mainly consisted of a large number of fine grains and a few coarse grains (CGs). In addition, several deformed structures were also observed. As the annealing time increased to 10 and 30 min, the fraction of CGs increased, and a bimodal grain size distribution was obtained, while the deformed structures were still present. The temperature of the reverse phase transformation of α′-M → γ was lower than the recrystallization temperature, which may be the main reason for the bimodal grain distribution. With this bimodal grain structure, the alloy exhibited a combination tensile strength of 543.3 MPa and an average elongation of 34.1%.

Similar content being viewed by others

References

Y.M. Wang, M.W. Chen, F.H. Zhou, and E. Ma, High Tensile Ductility in a Nanostructured Metal, Nature, 2002, 419(6910), p 912–914

Y.H. Zhao, X.Z. Liao, S. Cheng, E. Ma, and Y.T. Zhu, Simultaneously Increasing the Ductility and Strength of Nanostructured Alloys, Adv. Mater., 2006, 18(17), p 2280–2283

T. Shanmugasundaram, B.S. Murty, and V.S. Sarma, Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling, Scr. Mater., 2006, 54(12), p 2013–2017

B. Roy, R. Kumar, and J. Das, Effect of Cryorolling on the Microstructure and Tensile Properties of Bulk Nano-Austenitic Stainless Steel, Mater. Sci. Eng., A, 2015, 631, p 241–247

P. Nageswara rao, D. Singh, and R. Jayaganthan, Effect of Post Cryorolling Treatments on Microstructural and Mechanical Behaviour of Ultrafine Grained Al-Mg-Si Alloy, J. Mater. Sci. Technol., 2014, 30(10), p 998–1005

N. Rangaraju, T. Raghuram, B.V. Krishna, K.P. Rao, and P. Venugopal, Effect of Cryo-Rolling and Annealing on Microstructure and Properties of Commercially Pure Aluminium, Mater. Sci. Eng., A, 2005, 398(1), p 246–251

P. Bhaskar, A. Dasgupta, V.S. Sarma, U.K. Mudali, and S. Saroja, Mechanical Properties and Corrosion Behaviour of Nanocrystalline Ti-5Ta-1.8 Nb Alloy Produced by Cryo-Rolling, Mater. Sci. Eng., A, 2014, 616, p 71–77

S.K. Panigrahi and R. Jayaganthan, Development of Ultrafine-Grained Al 6063 Alloy by Cryorolling with the Optimized Initial Heat Treatment Conditions, Mater. Des., 2011, 32(4), p 2172–2180

J.J. Zheng, C.S. Li, S. He, B. Cai, and Y.L. Song, Microstructural and Tensile Behavior of Fe-36% Ni Alloy After Cryorolling and Subsequent Annealing, Mater. Sci. Eng., A, 2016, 670, p 275–279

J.J. Zheng, C.S. Li, S. He, B. Cai, and Y.L. Song, Deformation Behavior of Fe-36Ni Steel during Cryogenic (123-173 K) Rolling, Iron Steel Res. Int., 2016, 23(5), p 447–452

D.A. Colling, Martensite-to-Austenite Reverse Transformation in Fe-Ni-Co Alloys, Mater. Trans., 1970, 1(6), p 677–1682

K. Sridharan, F.J. Worzala, and R.A. Dodd, Heat Treatment and Microstructure of an Fe-Ni-Co Invar Alloy Strengthened by Intermetallic Precipitation, Mater. Chem. Phys., 1992, 29(4), p 115–119

R.K. Gupta, P. Varma, V.A. Kumar, P. Sarkar, J. Desai, and P. Ramkumar, Processing and Characterization of Superinvar for Space Application, Mater. Sci. Forum, 2015, 830, p 30–33

K. Sridharan, F.J. Worzala, and R.A. Dodd, Martensitic Transformation and Invar Effect in Fe-Ni-Co Alloys, Mater. Chem. Phys., 1991, 30(2), p 115–119

Q. Yang and J.L. Luo, Martensite Transformation and Surface Cracking of Hydrogen Charged and Outgassed Type 304 Stainless Steel, Mater. Sci. Eng., A, 2000, 288(1), p 75–83

T. Maki, S. Shimooka, M. Umemoto, and I. Tamura, The Morphology of Strain Induced Martensite and Thermally Transformed Martensite in Fe-Ni-C Alloys, J. Jpn. I. MET, 1972, 13(6), p 400–407

J.P. Du, C.Y. Wang, and T. Yu, The Ternary Ni-Al-Co Embedded-Atom-Method Potential for γ/γ′ Ni-Based Single-Crystal Superalloys: Construction and Application, Chin. Phys. B, 2014, 23(3), p 033401

C.G. Tian, G.M. Han, C.Y. Cui, and X.F. Sun, Effects of Co Content on Tensile Properties and Deformation Behaviors of Ni-Based Disk Superalloys at Different Temperatures, Mater. Des., 2015, 88, p 123–131

L.Y. Qing, J.S. Lian, Z.G. Jiang, G.Y. Wang, and Q. Jiang, Dual-Phase Nanocrystalline Ni-Co Alloy with High Strength and Enhanced Ductility, J. Mater. Res., 2010, 25(2), p 401–405

V.S. Sarma, J. Wang, W.W. Jian, A. Kauffmann, H. Conrad, J. Freudenberger, and Y.T. Zhu, Role of Stacking Fault Energy in Strengthening Due to Cryo-Deformation of FCC Metals, Mater. Sci. Eng., A, 2010, 527(29), p 7624–7630

X.Y. Cui, H.W. Yen, S.Q. Zhu, R. Zheng, and S.P. Ringer, On the Universality of Suzuki Segregation in Binary Mg Alloys from First Principles, J. Alloys Compd., 2015, 620, p 38–41

T.L. Achmad, W.X. Fu, H. Chen, C. Zhang, and Z.G. Yang, Effects of Alloying Elements Concentrations and Temperatures on the Stacking Fault Energies of Co-Based Alloys by Computational Thermodynamic Approach and First-Principles Calculations, J. Alloys Compd., 2017, 694, p 1265–1279

Z. Lee, D.B. Witkin, V. Radmilovic, E.J. Lavernia, and S.R. Nutt, Bimodal Microstructure and Deformation of Cryomilled Bulk Nanocrystalline Al-7.5 Mg Alloy, Mater. Sci. Eng., A, 2005, 410, p 462–467

K.S. Raju, V.S. Sarma, A. Kauffmann, Z. Hegedüs, J. Gubicza, M. Peterlechner, J. Freudenberger, and G. Wilde, High Strength and Ductile Ultrafine-Grained Cu-Ag Alloy Through Bimodal Grain Size, Dislocation Density and Solute Distribution, Acta Mater., 2013, 61(1), p 228–238

D.K. Yang, P.D. Hodgson, and C.E. Wen, Simultaneously Enhanced Strength and Ductility of Titanium Via Multimodal Grain Structure, Scr. Mater., 2010, 63(9), p 941–944

H. Li, Z. Jiang, and Z. Zhang, Effect of Grain Size on Mechanical Properties of Nickel-Free High Nitrogen Austenitic Stainless Steel, J. Iron Steel Res. Int., 2009, 16(1), p 58–61

Acknowledgments

The authors are grateful for the joint financial support from the National Natural Science Foundation of China and Baowu Steel Group Co. Ltd. (Grant No. U1660205).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Zheng, J., He, S. et al. Microstructure and Tensile Properties of the Fe-32%Ni-4%Co Alloy During Cryorolling and Subsequent Annealing. J. of Materi Eng and Perform 27, 6657–6664 (2018). https://doi.org/10.1007/s11665-018-3746-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3746-3