Abstract

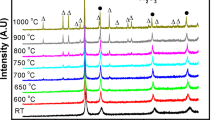

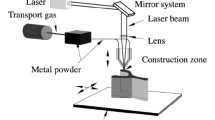

Phase composition and structural features of nickel-based alloy EP741 obtained by high-speed direct laser deposition were discussed in the paper. The technology of high-speed direct laser deposition has been successfully applied during the formation of samples with the various operating parameters of the experimental device. The laser power was between 450 and 1200 W, the scanning speed was 1.2 mm/s, the powder feed rate was 45 g/min, and the laser beam diameter was 1.2 mm. The structure and phase composition of the initial material and as-deposited samples were studied using optical and scanning electron microscopy, x-ray analysis and transmission electron microscopy. The investigation has shown that spherical particles of powder (EP741) can be used to form products by additive manufacturing with the presence of additional heat treatment, since almost all the as-deposited samples obtained do not contain cracks, and large volume of pores was observed only in the sample obtained with the power of 450 W. In addition, the phase composition of the as-deposited samples showed a high content of precipitating phase Ni3(Al, Ti) in matrix, which is coherent to the solid solution based on nickel. In theory, the presence of Ni3(Al, Ti) phase corresponds to the heat-treated nickel-base alloy obtained by standard methods of processing.

Similar content being viewed by others

References

T. Wohler, Wohlers Report 2015: Additive Manufacturing and 3D Printing State of the Industry: Annual Worldwide Progress Report

A. Polonsky, M.P. Echlin, W.C. Lenthe, R. Dehoff, M. Kirka, and T. Pollock, Defects and 3D Structural Inhomogeneity in Electron Beam Additively Manufactured Inconel 718, Mater. Charact., 2018, 1, p 2018

Xu Fujia, Yaohui Lv, Yuxin Liu, Xu Binshi, and Peng He, Effect of Heat Treatment on Microstructure and Mechanical Properties of Inconel 625 Alloy Fabricated by Pulsed Plasma Arc Deposition, Phys. Proc., 2013, 50, p 48–54

R.G. Ding, Z.W. Huang, H.Y. Li, I. Mitchell, G. Baxter, and P. Bowen, Electron Microscopy Study of Direct Laser Deposited IN718, Mater. Charact., 2015, 106, p 324–337

L. Murr, E. Martinez, K. Amato, S. Gaytan, J. Hernandez, D. Ramirez, P. Shindo, F. Medina, and R. Wicker, Fabrication of Metal and Alloy Components by Additive Manufacturing: Examples of 3D Materials Science, J. Mater. Res. Technol., 2012, 1, p 42–54

G.P. Dindaa, A.K. Dasguptaa, and J. Mazumderb, Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability, Mater. Sci. Eng. A, 2009, 509, p 98–104

F. Xu, Y. Lv, Y. Liu, F. Shu, P. He, and B. Xu, Microstructural Evolution and Mechanical Properties of Inconel 625 Alloy During Pulsed Plasma Arc Deposition Process, J. Mater. Sci. Technol., 2013, 29, p 480–488

J. Yang, Q. Zheng, H. Zhang, X. Sun, H. Guan, and Zh Hu, Effects of Heat Treatments on the Microstructure of IN792 Alloy, Mater. Sci. Eng. A, 2010, 527, p 1016–1021

G.A. Turichin, O.G. Klimova, E.V. Zemlyakov, K.D. Babkin, D.Y. Kolodyazhnyy, F.A. Shamray, and P.V. Petrovskiy, Technological Aspects of High Speed Direct Laser Deposition Based on Heterophase Powder Metallurgy, Phys. Proc., 2015, 78, p 397–406

G.A. Turichin, V.V. Somonov, К.D. Babkin, E.V. Zemlyakov and O.G. Klimova, High-speed direct laser deposition: technology, equipment and materials, in IOP Conference Series: Materials Science and Engineering, vol. 125 (2016)

G.A. Turichin, V.V. Somonov, and O.G. Klimova, Investigation and Modeling of the Process of Formation of the Pad Weld and Its Microstructure During Laser Cladding by Radiation of High Power Fiber Laser, Appl. Mech. Mater., 2018, 682, p 160–165

G. Turichin, O. Klimova, E. Zemlyakov, K. Babkin, and V. Somonov, Technological Bases of High-Speed Direct Laser Growth of Products by Heterophase Powder Metallurgy Method, Fotonika, 2015, 4, p 68–83

M.O. Sklyar, G.A. Turichin, O.G. Klimova, O.G. Zotov, and I.K. Topalov, Microstructure of 316L Stainless Steel Components Produced by Direct Laser Deposition, Steel Transl., 2016, 46, p 883–887

O. Klimova-Korsmik, G. Turichin, E. Zemlyakov, K. Babkin, and P. Petrovsky, Technology of High-Speed Direct Laser Deposition from Ni-Based Superalloys, Phys. Proc., 2016, 83, p 716–722

G. Turichin, E. Zemlyakov, and O. Klimova, Hydrodynamic Instability in High-Speed Direct Laser Deposition for Additive Manufacturing, Phys. Proc., 2016, 83, p 674–683

B.A. Kolachev, V.I. Elagin, and V.A. Livanov, Metallovedenie i Termicheskaya Obraboted Tsvetnukh Metallov i Splavov (Physical Metallurgy and Het Treatment of Non-Ferrous Metals and alloys), MISiS, Moscow, 1999, p 416

J. Li and H.M. Wang, Microstructure and Mechanical Properties of Rapid Directionally Solidified Ni-Base Superalloy Rene’41 by Laser Melting Deposition Manufacturing, Mater. Sci. Eng. A, 2010, 527, p 4823–4829

Y.Q. Chen, E. Francis, J. Robson, M. Preuss, and S.J. Haigh, Compositional Variations for Small-Scale Gamma Prime (γ′) Precipitates Formed at Different Cooling Rates in an Advanced Ni-Based Superalloy, Acta Mater., 2015, 85, p 199–206

G.R. Thellaputta, P. Subhash, C. Bose, and C.S.P. Rao, Machinability of Nickel Based Superalloys: A Review, Mater. Today Proc., 2017, 4, p 3712–3721

L. Thijs, M. Montero Sistiaga, R. Wauthle, Q. Xie, J. Kruth, and J. Humbeeck, Strong Morphological and Crystallographic Texture and Resulting Yield Strength Anisotropy in Selective Laser Melted Tantalum, Acta Mater., 2013, 63, p 4657–4668

A.G. Evgenov, A.M. Rogalev, S.V. Nerush, and I.S. Mazalov, Issledovanie svojstv splava EP648, poluchennogo motodom selektivnogo lazernogo splavleniya metallicheskih poroshkov (Investigation of the Properties of the EP648 Alloy Obtained by the Selective Laser Alloying of Metallic Powders), Trudi VIAM, 2016, 2, p 2

X. Lin and T.M. Yue, Phase Formation and Microstructure Evolution in Laser Rapid Forming of Graded SS316L/Rene88DT Alloy, Mater. Sci. Eng. A, 2005, 402, p 294–306

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu, The Metallurgy and Processing Science of Metal Additive Manufacturing, Int. Mater. Rev., 2016, 61, p 315–360

R.G. Dinga, Z.W. Huanga, H.Y. Li, I. Mitchell, G. Baxter, and P. Bowena, Electron Microscopy Study of Direct Laser Deposited IN718, Mater. Charact., 2015, 106, p 324–337

S. Khan, J. Singh, and A. Verma, Precipitation Behaviour of γ′ Phase in Alloy 693, Mater. Charact., 2016, 119, p 24–33

F. Li, R. Fu, F. Yin, D. Feng, H. Wang, G. Du, and Y. Feng, Impact of γ′(Ni3(Al, Ti)) Phase on Dynamic Recrystallization of a Ni-Based Disk Superalloy During Isothermal Compression, J. Alloys Compd., 2017, 693, p 1076–1082

E.E. Kornienko, A.A. Nikulina, A.G. Bannov, V.I. Kuz’min, M. Mildebrath, V.A. Bezrukova, and A.A. Zhoidik, The Influence of Flowing Temperature on the Structure and Properties of the Self-Fluxing Coatings, Met. Work. Mater. Sci., 2016, 73, p 52–56

V. Livescu, C.M. Knapp, G.T. Gray III, R.M. Martinez, B.M. Morrow and B.G. Ndefru, Additively Manufactured Tantalum Microstructures. Materialia (2018, In Press, Corrected Proof)

C. Zeng, W. Tian, W.H. Liao, and L. Hua, Microstructure and Porosity Evaluation in Laser-Cladding Deposited Ni-Based Coatings, Surf. Coat. Technol., 2016, 294, p 122–130

Acknowledgment

Investigations were conducted at NSTU Materials Research Center.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashkovets, M., Nikulina, A., Turichin, G. et al. Microstructure and Phase Composition of Ni-Based Alloy Obtained by High-Speed Direct Laser Deposition. J. of Materi Eng and Perform 27, 6398–6406 (2018). https://doi.org/10.1007/s11665-018-3722-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3722-y