Abstract

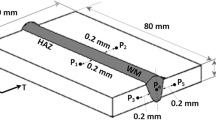

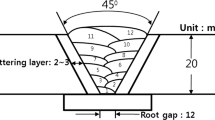

The precipitation of the intermetallic phases can impair mechanical and corrosion properties. In the case of lean duplex stainless steels, they present solidification mode as primary ferrite, with austenite precipitation in the solid state, during cooling. This means the heat-affected zone balanced microstructure can be changed during the welding by the cooling rate, which is associated to the welding heat input, the thickness of the plate and the physical properties of the material. This work intends to present the influence of welding heat input on the corrosion resistance of UNS S82441 lean duplex stainless steel. The gas metal arc welding process was used to make the weld beads, using ER2209 as filler metal, which characterizes a dissimilar welded joint. The corrosion resistance of these specimens was analyzed through scanning vibrating electrode technique. It was observed that welding heat input variation distinctly influences corrosion in different zones of the weld beads over the specimen exposure time. The weld bead under intermediate welding heat input showed the highest corrosion rate and the one under the highest welding heat input, the lowest corrosion rate intensity.

Similar content being viewed by others

References

S.D. Brandi., Weldability of Duplex Stainless Steels, AWS. (Org.). AWS Welding Handbook, vol. 4, 9a.ed. Miami: American Welding Society, 2011, p 351-368

N. Sridhar, J. Kolts, and L.H. Flasche, A Duplex Stainless Steel for Chloride Environmnents, J. Met., 1985, 37(3), p 31–35

J. Street, Welding Duplex Stainless Steel for Arduous Service, Met. Constr., 1986, 18(9), p 565–569

ASM, American Society for Metals, Proprieties and Selection: Irons, Steels and High Performance Alloys, ASM International Metals Handbook, 1990, 1.

A.F. Padilha, R.L. Plaut, I. Alvares-Armas, and S. Degallaix-Moreuli, Phase transformation and microstructure, Duplex Stainless Steels, 1, ISTE Ltd and John Wiley & Sons, London, 2009, p 115–139

A.J. Griffiths, A. Turnbull, Performance of Duplex Stainless Steels in Oilfield Environments, Proceedings, 1, Netherlands Society for Materials Science, 1, L.A.J.L. Sarton, H.B. Zeedijk (Eds.), Zwijndrecht, 1997, p 79-82.

H.H. Uhlig, Uhlig’s Corrosion Handbook, Edited by R. Winston Revie, 3rd ed., Wiley, USA, 2011

R.N. Gunn, Duplex Stainless Steels: Microstructure, Properties AND Applications, Cambridge, England, 2003, Ed. by Gunn R.N., Abington Publishing.

A.J.R. Londono, J.C. Lippold, and S.D. Brandi, Relationship Between Chromium Nitride and Secondary Austenite Precipitation in Duplex Stainless Steels, Metall. Mater. Trans. A, 2003, 34A, p 1575–1597

J.R. Davis, Corrosion of Duplex Stainless Steel Weldments. Corrosion of Weldments, ASM International, Materials Park, 2006

A.I. Armas and D.S. Moreuli, Duplex Stainless Steels, ISTE Ltd and Wiley, 2009, 1, p 141–159

M. Eghtesad, B.Y. Lari, and B. Assadsangabi, Stability Analysis and Internal Dynamics of MIMO GMAW Process, 2008, 17th World Congress the International Federation of Automatic Control IFAC, p 14834-14839

E.A. Pauli, C.G. Schon, and S.D. Brandi, Multicomponent Phase Diagram of Lean Duplex Stainless Steel UNS S82441 and Its Application to Evaluate the Microstructure in the Heat Affected Zone, J. Phase Equilib. Diffus., 2017, 38, p 332–342

A.C. Bastos, M.C. Quevedo, O.V. Karavai, and M.G.S. Ferreira, On the Application of the Scanning Vibrating Electrode Technique (SVET) to Corrosion Research, J. Electrochem. Soc., 2017, 164(14), p C973–C990

R.M. Souto, Y. González-García, A.C. Bastos, and A.M. Simões, Investigating Corrosion Processes in the Micrometric Range: A SVET Study of the Galvanic Corrosion of Zinc Coupled with Iron, Corris. Sci., 2007, 49, p 4568–4580

J.O. Nilson and A. Wilson, Influence of Ishothermal Phase Transformations on Toughnees and Pitting Corrosion of Super Duplex Stainless Steel SAF 2507, Mater. Sci. Technol., 1993, 9, p 545–554

E. Folkhard, Welding Metallurgy of Stainless Steel, Springer, Germany, 1994

J.O. Nilson, The Physical Metallurgy of Duplex Stainlees Steel, Conf. Duplex Stainl. Steel, 1997, 97, p 73–82

C. Shek, K.W. Wong, and J.K.L. Lai, Review of Temperature Indicators and the Use of Duplex Stainless Steels for Life Assessment, Mater. Sci. Eng., 1996, R19, p 153–200

J. Honeycombe, and T.G. Gooch, Arc Welding Ferritic-Austenitic Stainless Steels: Prediction of Weld Area Microstructures, Welding Institute Research Report, 1985, p 286

D.N. Noble, T.G. Gooch, Factors Controlling the Ferrite/Austenite Balance in Arc Welded 22Cr/5Ni/2.5Mo/N Duplex Stainless Steel, 1986, Welding Institute Research Report, p 321

N. Sterphenson, Welding Status of Duplex Stainless Steels for Offshore Application—Part I, Weld. Met. Fabr., 1987, 55, p 159–164

A.I. Armas, Duplex Stainless Steels: Brief History and Some Recent Alloys, Recent Patents Mech. Eng., 2008, 1, p 51–57

M. Yousefieh, M. Shamanian, and A. Saatchi, Influence of Step Annealing Temperature on the Microstructure and Pitting Corrosion Resistance of SDSS UNS S32760 Welds, J. Mater. Eng. Perform., 2011, 20(9), p 1678–1683

Acknowledgments

The authors appreciate Outokumpu for the donation of UNS S82441 duplex stainless steel plates, the University of São Paulo for the physical structure used in the tests and Voith Hydro for supplying the filler metals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Pauli, E.A., Cotting, F., Junior, J.C.S. et al. Welding Heat Input Influence on UNS S82441 Lean Duplex Stainless Steel Corrosion Resistance Assessed by Scanning Vibrating Electrode Technique (SVET). J. of Materi Eng and Perform 27, 6389–6397 (2018). https://doi.org/10.1007/s11665-018-3721-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3721-z