Abstract

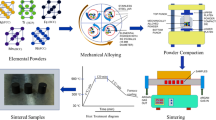

In this study, a series of lightweight Al–Mg system entropic alloys containing Zn, Cu, and Si were designed based on the order/disorder or entropy, and eutectic concepts. The alloys of Al58.5Mg31.5Zn4.5Cu4.5Si1; Al63Mg27Zn4.5Cu4.5Si1; Al66.7Mg23.3Zn4.5Cu4.5Si1; Al80Mg14Zn2.7Cu2.7Si0.6; Al85Mg10.5Zn2.025Cu2.025Si0.45; and Al90Mg7Zn1.35Cu1.35Si0.3 were prepared by induction melting under a high-purity argon atmosphere and then casted into stainless steel molds. The microstructures which were tested in the as-cast state exhibited multiphases and contained apparent volume fractions of intermetallic compounds and solid solutions. Then, the compressive mechanical properties of the alloys were measured, and high fracture strengths of 577, 677, 590, 498, 814, and 794 MPa, respectively, were determined. Strong hardening phenomena were observed in the Al80Mg14Zn2.7Cu2.7Si0.6, Al85Mg10.5Zn2.025Cu2.025Si0.45, and Al90Mg7Zn1.35Cu1.35Si0.3 alloys at room temperature, with amazing plasticity percentages of 13.8, 24.8, and 32.7%, respectively. The property differences in the lightweight alloys were analyzed using the following parameters: the critical values of the enthalpy of mixing; atomic size differences; ratio of entropy to enthalpy; valence electron concentration (VEC); and Pauling electronegativity difference. Finally, three of the aforementioned parameters (atomic size difference, enthalpy of mixing, and Pauling electronegativity difference) were regarded in this study as the crucial rules for the lightweight multicomponent alloys.

Similar content being viewed by others

References

Z. Li, K.G. Pradeep, Y. Deng et al., Metastable High-Entropy Dual-Phase Alloys Overcome The Strength-Ductility Trade-Off, Nature, 2016, 534, p 227–230

W. Zhang, P.K. Liaw, and Y. Zhang, Science and Technology in High-Entropy Alloys, Sci. China Mater., 2018, 61(1), p 2–22

Y. Zhang, T.T. Zuo, Z. Tang et al., Microstructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1–93

J.W. Yeh, S.Y. Chang, Y.D. Hong et al., Anomalous Decrease in X-ray Diffraction Intensities of Cu-Ni-Al-Co-Cr-Fe-Si Alloy Systems with Multi-principal Elements, Mater. Chem. Phys., 2007, 103, p 41–46

R.X. Li, P.K. Liaw, and Y. Zhang, Synthesis of AlxCoCrFeNi High-Entropy Alloys by High-Gravity Combustion from Oxides, Mater. Sci. Eng. A, 2017, 707, p 668–763

Y. Zou, S. Maiti, W. Steurer et al., Size-Dependent Plasticity in an Nb25Mo25Ta25W25, Refractory High-Entropy Alloy, Acta Mater., 2014, 65, p 85–97

Y.J. Zhou, Y. Zhang, Y.L. Wang et al., Solid Solution Alloys of AlCoCrFeNiTix with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90, p 181904–181904-3

Y. Zhang, G.L. Chen et al., Phase Change and Mechanical Behaviors of TixCoCrFeNiCu1−yAly High Entropy Alloys, J. ASTM Int., 2010, 7, p 1–8

Y.J. Hsu, W.C. Chiang, and J.K. Wu, Corrosion Behavior of FeCoNiCrCux, High-Entropy Alloys in 3.5% Sodium Chloride Solution, Mater. Chem. Phys., 2005, 92, p 112–117

C.P. Lee, Y.Y. Chen, C.Y. Hsu et al., The Effect of Boron on the Corrosion Resistance of the High Entropy Alloys Al0.5CoCrCuFeNiBx, J. Electrochem. Soc., 2007, 154, p C424–C430

Z. Tang, L. Huang, W. He et al., Alloying and Processing Effects on the Aqueous Corrosion Behavior of High-Entropy Alloys, Entropy, 2014, 16, p 895–911

C.J. Tong, Y.L. Chen, and J.W. Yeh, Mechanical Performance of the AlxCoCrCuFeNi High-Entropy Alloy System with Multiprincipal Elements, Metall. Mater. Trans. A, 2005, 36, p 1263–1271

M.R. Chen, S.J. Lin, J.W. Yeh et al., Effect of Vanadium Addition on the Microstructure, Hardness, Wear Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy, Metall. Mater. Trans. A, 2006, 37, p 1363–1369

C.Y. Hsu, J.W. Yeh, S.K. Chen et al., Wear Resistance and High-Temperature Compression Strength of FCC CuCoNiCrAl0.5Fe Alloy with Boron Addition, Metall. Mater. Trans. A, 2004, 35, p 1465–1469

M.H. Chuang, M.H. Tsai, W.R. Wang et al., Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy, High-Entropy Alloys, Acta Mater., 2011, 59, p 6308–6317

Y. Shi, B. Yang, and P.K. Liaw, Corrosion-Resistant High-Entropy Alloys: A Review, Met. Open Access Metall. J., 2017, 7(2), p 43

Y. Shi, B. Yang, X. Xie et al., Corrosion of AlxCoCrFeNi High-Entropy Alloys: Al-Content and Potential Scan-Rate Dependent Pitting Behavior, Corros. Sci., 2017, https://doi.org/10.1016/j.corsci.2017.02.019

Y. Shi, L. Collins, R. Feng et al., Homogenization of AlxCoCrFeNi High-Entropy Alloys with Improved Corrosion Resistance, Corros. Sci., 2018, https://doi.org/10.1016/j.corsci.2018.01.030

Y.J. Zhou, Y. Zhang, Y.L. Wang et al., Microstructure and Compressive Properties of Multicomponent Alx(TiVCrMnFeCoNiCu)100−x, High-Entropy Alloys, Mater. Sci. Eng. A, 2007, s454–455, p 260–265

F.J. Wang, Y. Zhang, G.L. Chen et al., Tensile and Compressive Mechanical Behavior of a CoCrCuFeNiAl0.5 High Entropy Alloy, Int. J. Mod. Phys. B, 2012, 23, p 1254–1259

T.T. Shun and Y.C. Du, Age Hardening of the Al0.3CoCrFeNiC0.1, High Entropy Alloy, J. Alloys Compd., 2009, 478, p 269–272

O.N. Senkov, G.B. Wilks, J.M. Scott et al., Mechanical properties of Nb25Mo25Ta 25W25, V20Nb20Mo20Ta20W20, Refractory High Entropy Alloys, Intermetallics, 2011, 19, p 698–706

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov et al., Tensile Properties of an AlCrCuNiFeCo High-Entropy Alloy in As-Cast and Wrought Conditions, Mater. Sci. Eng. A, 2012, 533, p 107–118

F. Otto, A. Dlouhý, C. Somsen et al., The Influences of Temperature and Microstructure on the Tensile Properties of a CoCrFeMnNi High-Entropy Alloy, Acta Mater., 2013, 61, p 5743–5755

Y. Zhang, T.T. Zuo, Y.Q. Cheng et al., High-Entropy Alloys with High Saturation Magnetization, Electrical Resistivity, Malleability, Sci. Rep., 2013, 3, p 1455

Y.F. Kao, S.K. Chen, T.J. Chen et al., Electrical, Magnetic, Hall Properties of AlxCoCrFeNi High-Entropy Alloys, J. Alloys Compd., 2011, 509, p 1607–1614

K.M. Youssef, A.J. Zaddach, C. Niu et al., A Novel Low-Density, High-Hardness, High-Entropy Alloy with Close-Packed Single-Phase Nanocrystalline Structures, Mater. Res. Lett., 2014, 2, p 95–99

O.N. Senkov, S.V. Senkova, C. Woodward et al., Low-Density, Refractory Multi-Principal Element Alloys of the Cr-Nb-Ti-V-Zr System: Microstructure and Phase Analysis, Acta Mater., 2013, 61, p 1545–1557

O.N. Senkov, S.V. Senkova, D.B. Miracle et al., Mechanical Properties of Low-Density, Refractory Multi-Principal Element Alloys of the Cr-Nb-Ti-V-Zr System, Mater. Sci. Eng. A, 2014, 565, p 51–62

R. Feng, M.C. Gao, C. Lee et al., Design of Light-Weight High-Entropy Alloys, Entropy, 2016, 18(9), p 333

R. Feng, M.C. Gao, C. Zhang et al., Phase Stability and Transformation in a Light-Weight High-Entropy Alloy, Acta Materialia, 2018, https://doi.org/10.1016/j.actamat.2017.12.061

Y. Qiu, Y.J. Hu, A. Taylor et al., A Lightweight Single-Phase AlTiVCr Compositionally Complex Alloy, Acta Mater., 2017, 123, p 115–124

R. Li, J.C. Gao, and K. Fan, Study to Microstructure and Mechanical Properties of Mg Containing High Entropy Alloys, Mater. Sci. Forum, 2010, 650, p 265–271

R. Li, J.C. Gao, and K. Fan, Microstructure and Mechanical Properties of MgMnAlZnCu High Entropy Alloy Cooling in Three Conditions, Mater. Sci. Forum, 2011, 686, p 235–241

E.J. Baek, T.Y. Ahn, J.G. Jung et al., Effects of Ultrasonic Melt Treatment and Solution Treatment on the Microstructure and Mechanical Properties of Low-Density Multicomponent Al70Mg10Si10Cu5Zn5 Alloy, J. Alloys Compd, 2016, https://doi.org/10.1016/j.jallcom.2016.11.305

T.Y. Ahn, J.G. Jung, E.J. Baek et al., Temperature Dependence of Precipitation Behavior of Al-6Mg-9Si-10Cu-10Zn-3Ni Natural Composite and Its Impact On Mechanical Properties, Mater. Sci. Eng. A, 2017, 695, p 45–54

T.Y. Ahn, J.G. Jung, E.J. Baek et al., Temporal Evolution of Precipitates in Multicomponent Al-6Mg-9Si-10Cu-10Zn-3Ni Alloy Studied by Complementary Experimental Methods, J. Alloys Compd., 2017, 701, p 660–668

X. Yang, S.Y. Chen, J.D. Cotton et al., Phase Stability of Low-Density, Multiprincipal Component Alloys Containing Aluminum, Magnesium, Lithium, JOM, 2014, 66, p 1–4

Y. Zhang, X. Yang, and P.K. Liaw, Alloy Design and Properties Optimization of High-Entropy Alloys, JOM, 2012, 64, p 830–838

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10, p 534–538

Y. Zhang and Y.J. Zhou, Solid Solution Formation Criteria for High Entropy Alloys, Trans. Tech Publ., 2007, 561, p 1337–1339

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Prog. Nat. Sci. Mater., 2011, 21, p 433–446

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132, p 233–238

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of Valence Electron Concentration on Stability of FCC or BCC Phase in High Entropy Alloys, J. Appl. Phys., 2011, 109, p 103505

O.N. Senkov, G.B. Wilks, D.B. Miracle et al., Refractory High-Entropy Alloys, Intermetallics, 2010, 18, p 1758–1765

O.N. Senkov, J.M. Scott, S.V. Senkova et al., Microstructure and Room Temperature Properties of A High-Entropy TaNbHfZrTi alloy, J. Alloy. Compd., 2011, 509, p 6043–6048

O.N. Senkov and C.F. Woodward, Microstructure and Properties of a Refractory NbCrMo0.5Ta0.5TiZr Alloy, Mater Sci Eng A, 2011, 529, p 311–320

J.W. Yeh, S.Y. Chang, Y.D. Hong et al., Anomalous Decrease in X-ray Diffraction Intensities of Cu–Ni–Al–Co–Cr–Fe–Si Alloy Systems with Multi-principal Elements, Mater Chem Phys, 2007, 103, p 41–46

J.W. Yeh, S.J. Lin, T.S. Chin et al., Formation of Simple Crystal Structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V Alloys with Multiprincipal Metallic Elements, Metall. Mater. Trans. A, 2004, 35, p 2533–2536

Y.J. Zhou, Y. Zhang, Y.L. Wang et al., Solid Solution Alloys of AlCoCrFeNiTix with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90, p 181904–181904-3

S.P. Rudman, Phase stability in metals and alloys, McGraw-Hill, New York, 1967

Q.W. Xing and Y. Zhang, Amorphous Phase Formation Rules in High-Entropy Alloys, Chin. Phys. B, 2017, 26, p 18104–018104

Acknowledgments

YZ would like to acknowledge the financial support for this research study provided by the National Natural Science Foundation of China (NSFC, 51471025, 51671020). LS would like to thank Dr. X Yang and Ms DY Li for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at “AeroMat 2017,” held April 10-12, 2017, in Charleston, South Carolina, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Shao, L., Zhang, T., Li, L. et al. A Low-Cost Lightweight Entropic Alloy with High Strength. J. of Materi Eng and Perform 27, 6648–6656 (2018). https://doi.org/10.1007/s11665-018-3720-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3720-0