Abstract

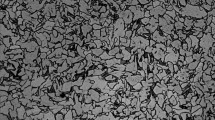

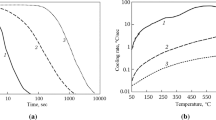

The continuous cooling transformation (CCT) behavior of eight 2¼Cr-1Mo steels from a statistically designed matrix was determined. These steels contained two levels of carbon (0.07 and 0.16 wt.%), manganese (0.35 and 0.85%), chromium (1.5 and 2.8%), and molybdenum (0.3 and 1.25%). Each steel was tested in a quenching dilatometer at five to six cooling rates between 725 and 1.2 °C/min. For each CCT sample, the change in length, microstructure, and macrohardness were determined. The ferrite content was also measured for samples cooled near the ferrite nose. Pearson correlation and multiple regression analyses were performed for various CCT diagram parameters. The correlation analysis showed that carbon and chromium contents significantly affected the critical temperatures and the bainite and martensite transformation temperatures. Increasing carbon content significantly increased the hardness for the bainite and martensite range of cooling rates, but hardness at slower cooling rates was unaffected by alloying elements. Regression equations were obtained for the critical temperatures and the ferrite nose cooling rate.

Similar content being viewed by others

References

R.L. Klueh, P.J. Maziasz, and D.J. Alexander, Bainitic Chromium-Tungsten Steels with 3% Chromium, Metall. Mater. Trans. A, 1997, 28A(2), p 335–345A

R.L. Klueh, D.J. Alexander, and P.J. Maziasz, Fracture Behavior of Bainitic Chromium-Tungsten and Chromium-Molybdenum Steels, in Proceedings of 36th Mechanical Working and Steel Processing Conference, 16–19 October 1994, Baltimore, Maryland, IIS/AIME, 1994, p. 443–452

M.J. Xu, H. Lu, C. Yu, J.J. Xu, and J.M. Chen, Finite Element Simulation of Butt Welded 2.25Cr-1.6W Steel Pipe Incorporating Bainite Phase Transformation, Sci. Technol. Weld. Join., 2013, 18(3), p 184–190

Y. Luo, D.-A. Deng, and X.-L. Jiang, Prediction of Welding Residual Stress in 2.25Cr-1Mo Steel Pipe, J. Shanghai Jiaoting Univ. (Sci.), 2006, E-11(1), p 77–83

N. Parvathavarthini, S. Saroja, and R.K. Dayal, Hydrogen Transport in Chrome-Moly Steels and Susceptibility to Hydrogen Embrittlement: Correlation with Microstructure, in Proceedings of “ISOMALM 2000: International Symposium on Materials Ageing and Life Management, Kalpakkam, India, 3–6 October 2000, Allied Publishers Lt., New Delhi, 2000, p. 1045–1050

H. Na, B. Kim, S. Lee, and C.Y. Kang, Thermodynamic Alloy Design of High Strength and Toughness in 300 mm Thick Pressure Vessel Wall of 1.25Cr-0.5Mo Steel, Metals, 2018, 8, p 70. https://doi.org/10.3390/met8010070

B.J. Shaw, Study to Optimize Cr-Mo Steels to Resist Hydrogen and Temper Embrittlement (WEC-3.2.3), Contract No. DE-AC05-78-R13513, U.S. Department of Energy, Division of Coal Conversion, Quarterly Report No. 7, 1980

B.J. Shaw and J. Greggi, Study to Optimize Cr-Mo Steels to Resist Hydrogen and Temper Embrittlement (WEC-3.3), in Fossil Energy Materials Program Quarterly Progress Report, ORNL/FMP-82/4, for the Period Ending September 30, 1982, p. 123

B.J Shaw, Study to Optimize Cr-Mo Steels to Resist Hydrogen and Temper Embrittlement (WEC-3.3), in Fossil Energy Materials Program Quarterly Progress Report,” ORNL/FMP-83/2 for the Period Ending March 31, 1983, p. 177

B.J. Shaw, A Study of Carbides Formed in Low Alloy Cr-Mo Steels, in Research on Chrome-Moly Steels, MPC-21, American Society of Mechanical Engineers, New York, 1984, p. 117–128

T. Wada, G.T. Eldis, Transformation Characteristics of 2¼Cr-1Mo Steel, in Application of 2¼ Cr-1Mo Steel for Thick-Wall Pressure Vessels, G.S. Sangdahl and M. Semchyshen, Ed., American Society for Testing and Materials, 1982, p. 343–362

R. Petri, E. Schnabel, and P. Schwaab, On the Influence of the Alloying Elements on the Transformation and Precipitation Processes During Cooling of Creep-Resistant Tube Steels After Austenitizing—I. Chromium-Molybdenum Steels, Arch. Eisenhuttenwes., 1980, 51(8), p 355–360

C. Leumonie, J. Hennion, and L. Cadiou, Metallurgical Aspects of the Fabrication Aspects of Hydrocracking Equipment Made of 2.25% Cr-1% Mo, Rev. Metall., 1974, 21, p 683–697

T. Prnka, J. Purmensky, and A. Jakobova, The Influence of Thermomechanical Processing on the Microstructure and Mechanical Properties of 2¼ Cr-1%Mo Steel (15313), Hutn. Listy, 1971, 26(1), p 51

T. Kunitake, T. Yukitoshi, K. Yoshikawa, and H. Ohtani, Continuous Cooling Transformations of Steels for High Temperature Service, Sumitomo Kinzoku, 1970, 22(2), p 31–51

R. Ranjan and S.B. Singh, Bainite Transformation During Continuous Cooling: Analysis of Dilatation Data, Metall. Mater. Trans. A, 2018, 49A(1), p 88–93

G.T. Eldis, A Critical Review of Data Sources for Isothermal Transformation and Continuous Cooling Transformation Diagrams, Hardenability Concepts with Applications to Steel, D.V. Doane and J.S. Kirkaldy, Ed., TMS-AIME, Warrendale, 1978, p 126–157

J. Trzaska and L.A. Dobrzanski, Modelling of CCT Diagrams for Engineering and Constructional Steels, J. Mater. Process. Technol., 2007, 192, p 504–510

Acknowledgments

The authors gratefully acknowledge Bevil J. Shaw for his project activities to provide the source materials at the former Westinghouse R&D Center in Pittsburgh, PA and the permission of R. W. Swindeman of Oak Ridge National Laboratories to utilize the Charpy specimens tested in Department of Energy Contract No. DE-AC05-78ET13513. The authors wish to thank the management and staff of the Climax Molybdenum Company and Westinghouse for funding and performing some of the technical experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tartaglia, J.M., Kuelz, A.N. & Thelander, V.H. The Effects of Alloying Elements on the Continuous Cooling Transformation Behavior of 2¼Cr-1Mo Steels. J. of Materi Eng and Perform 27, 6349–6364 (2018). https://doi.org/10.1007/s11665-018-3683-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3683-1