Abstract

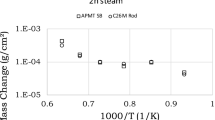

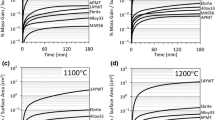

In order to investigate the oxidation process of FeCrAl alloy developed by NPIC under simulated LOCA conditions, three experimental groups of alloys were exposed to the steam atmosphere and heated to test temperature (550, 1000, and 1200 °C), respectively, and then maintained at the temperature for 4 hours. The oxidation kinetics of alloys were obtained with a high-precision synchronous thermal analyzer, and the oxide film was investigated by XPS, XRD, and SEM technologies. The results showed that the FeCrAl alloy still retains good oxidation resistance under 1200 °C steam atmosphere. The oxidation process of alloy at 1200 °C can be described into six stages.

Similar content being viewed by others

References

L.J. Ott, K.R. Robb, and D. Wnag, Preliminary Assessment of Accident-Tolerant Fuels on LWR Performance During Normal Operation and Under DB and BDB Accident Conditions, J. Nucl. Mater., 2014, 448(1–3), p 520–533

Yamamoto Y, Field KG, Snead LL. Optimization of Nuclear Grade FeCrAl Fuel Cladding for Light Water Reactors, Accident Tolerant Fuel Concepys for Light Water Beactors, IAEA Tecdoc Series, IAEA, USA, 2016, p 55–65

K.A. Terrani, C.M. Parish, D. Shin et al., Protection of Zirconium by Alumina-and Chromia-Forming Iron Alloys Under High-Temperature Steam Exposure, J. Nucl. Mater., 2013, 438(1–3), p 64–71

K.A. Terrani, S.J. Zinkle, and L.L. Snead, Advanced Oxidation-Resistant Iron-Based Alloys for LWR Fuel Cladding, J. Nucl. Mater., 2014, 448(1–3), p 420–435

Y. Yamamoto, B.A. Pint, K.A. Terrani et al., Development and Property Evaluation of Nuclear Grade Wrought FeCrAl Fuel Cladding for Light Water Reactors, J. Nucl. Mater., 2015, 467, p 703–716

M. Bachhav, G.R. Odette, and E.A. Marquis, Microstructural Changes in a Neutron-Irradiated Fe-15 at. % Cr Alloy, J. Nucl. Mater., 2014, 454(1), p 381–386

J.E. Pawel, A.F. Rowcliffe, G.E. Lucas et al., Irradiation Performance of Stainless Steels for ITER Application, J. Nucl. Mater., 1996, 239, p 126–131

H. Tanigawa, K. Shiba, A. Möslang et al., Status and Key Issues of Reduced Activation Ferritic/Martensitic Steels as the Structural Material for a DEMO Blanket, J. Nucl. Mater., 2011, 417(1–3), p 9–15

C. Badini and F. Laurella, Oxidation of FeCrAl Alloy: Influence of Temperature and Atmosphere on Scale Growth Rate and Mechanism, Surf. Coat. Technol., 2001, 135(2), p 291–298

F. Liu and K. Stiller, Atom Probe Tomography of Thermally Grown Oxide Scale on FeCrAl, Ultramicroscopy, 2013, 132, p 279–284

S. Dryepondt, A.R.V. Put, and B.A. Pint, Effect of H2O and CO2 on the Oxidation Behavior and Durability at High Temperature of ODS-FeCrAl, Oxid. Met., 2013, 79(5–6), p 627–638

D.J. Park, H.G. Kim, J.Y. Park et al., A Study of the Oxidation of FeCrAl Alloy in Pressurized Water and High-Temperature Steam Environment, Corros. Sci., 2015, 94, p 459–465

S. Okabe, M. Kohno, K. Ishii et al., Oxidation Resistance of Rapidly Solidified FeCrAl Ribbons at High Temperature, Mater. Sci. Eng. A, 1994, 181, p 1104–1108

M.W. Brumm and H.J. Grabke, The Oxidation Behaviour of NiAl-I. Phase Transformations in the Alumina Scale During Oxidation of NiAl and NiAl-Cr Alloys, Corros. Sci., 1992, 33(11), p 1677–1690

D. Pan, R. Zhang, H. Wang et al., Formation and Stability of Oxide Layer in FeCrAl Fuel Cladding Material Under High-Temperature Steam, J. Alloys Compd., 2016, 684, p 549–555

R.T. Sweet, N.M. George, G.I. Maldonado et al., Fuel Performance Simulation of Iron-Chrome-Aluminum (FeCrAl) Cladding During Steady-State LWR Operation, Nucl. Eng. Des., 2018, 328, p 10–26

S. Dryepondt, K.A. Unocic, D.T. Hoelzer et al., Development of Low-Cr ODS FeCrAl Alloys for Accident-Tolerant Fuel Cladding, J. Nucl. Mater., 2018, 501, p 59–71

K.A. Gamble, T. Barani, D. Pizzocri et al., An Investigation of FeCrAl Cladding Behavior Under Normal Operating and Loss of Coolant Conditions, J. Nucl. Mater., 2017, 491, p 55–66

M.N. Gussev, E. Cakmak, and K.G. Field, Impact of Neutron Irradiation on Mechanical Performance of FeCrAl Alloy Laser-Beam Weldments, J. Nucl. Mater., 2018, 504, p 221–233

K.G. Field, S.A. Briggs, K. Sridharan et al., Mechanical Properties of Neutron-Irradiated Model and Commercial FeCrAl Alloys, J. Nucl. Mater., 2017, 489, p 118–128

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51801194), the Sichuan applied basic research project (2018JY0430) and the International Science and Technology Cooperation Program of China (2015DFR60370).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Pan, D., Zhang, R., Wang, H. et al. In Steam Short-Time Oxidation Kinetics of FeCrAl Alloys. J. of Materi Eng and Perform 27, 6407–6414 (2018). https://doi.org/10.1007/s11665-018-3665-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3665-3