Abstract

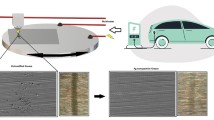

The aim of this work was to analyze the effect of biodiesel and diesel–biodiesel blends on the sliding wear behavior of AISI 440B martensitic stainless steel. Lubricated tests were performed on AISI 440B martensitic stainless steel samples using Brazilian commercial diesel (containing 7 vol.% biodiesel), pure biodiesel, and diesel–biodiesel blends with biodiesel additions of 20% v/v, 30% v/v, and 50% v/v. Non-lubricated tests were also performed. The stainless steel was analyzed in the as-received condition (annealed) and after heat treatments (quenched and tempered at different temperatures), using a pin-on-disk device with an alumina pin, at a 1.8 m/s sliding speed, 14.7 N load, and 4400 m sliding distance, following the ASTM G99-04 Standard. Wear track widths, wear coefficients, and wear track surfaces were analyzed by optical and scanning electron microscopy. The results showed that AISI 440B presented the worst wear behavior in the dry condition with a microstructure characterized by a ferritic matrix and dispersed carbides (annealed condition). The wear resistance increased with the increase in biodiesel content due to the matrix strengthening by the martensitic transformation (heat-treated condition). When the biodiesel content was superior to 50% v/v, a reverse result was found. The observed wear mechanism was abrasive in all conditions. A − 1.35 power law coefficient characterized the wear coefficient as a function of biodiesel content for the annealed condition and a − 0.95 power law coefficient for the heat-treated conditions.

Similar content being viewed by others

References

ANP – Brazilian National Agency for Petroleum, Oil, Gas and Biofuels. Law no 13263, 3.23.2016.

F.A. Almeida, M.M. Maru, L.N. Batista, F.J.A. Oliveira, R.R.F.S. Silva, and C.A. Achete, Wear and Friction Behaviour of Si3N4 Ceramics Under Diesel and Biodiesel Lubrication, J. Mater. Res. Technol., 2013, 2(2), p 110–116

A. Nicolau, C.V. Lutckmeier, D. Samios, M. Gutterres, and C.M.S. Piatnick, The Relation Between Lubricity and Electrical Properties of Low Sulfur Diesel and Diesel/Biodiesel Blends, Fuel, 2014, 117, p 26–32

A.S.M.A. Haseeb, S.Y. Sia, M.A. Fazal, and H.H. Masjuki, Effect of Temperature on Tribological Properties of Palm Biodiesel, Energy, 2010, 35, p 1460, 1464

M.A. Fazal, A.S.M.A. Haseeb, and H.H. Masjuki, Investigation of Friction and Wear Characteristics of Palm Biodiesel, Energy Convers. Manag., 2013, 67, p 251–256

M.A. Fazal, A.S.M.A. Haseeb, and H.H. Masjuki, A Critical Review on the Tribological Compatibility of Automotive Materials in Palm Biodiesel, Energy Convers. Manag., 2014, 79, p 180–186

M.H. Mosarof, M.A. Kalam, H.H. Masjuki, A.M. Ashraful, M.M. Rashed, H.K. Imdadul, and I.M. Monirul, Implementation of a Palm Biodiesel Based on Economic Aspects, Performance, Emission, and Wear Characteristics, Energy Manag., 2015, 105, p 617–629

F. Sundus, M.A. Fazal, and H.H. Masjuki, Tribology with Biodiesel: A Study on Enhancing Biodiesel Stability and its Fuel Properties, Renew. Sustain. Energy Rev., 2017, 70, p 399–412

A.K. Agarwal, J.G. Gupta, and A. Dhar, Potential and Challenges for Large-Scale Application of Biodiesel in Automotive Sector, Prog. Energy Combust. Sci., 2017, 61, p 113–149

M. Habibullah, H.H. Masjuki, M.A. Kalam, N.W.M. Zulkifli, B.M. Masum, A. Arslan, and M. Gulzar, Friction and Wear Characteristics of Calophyllum inophyllum Biodiesel, Ind. Crops Prod., 2015, 76, p 188–197

A. Dhar and A.K. Agarwal, Effect of Karanja Biodiesel Blend on Engine Wear in a Diesel Engine, Fuel, 2014, 134, p 81–89

M.S. Reddy, N. Sharma, and A.K. Agarwal, Effect of Straight Vegetable Oil and Blends and Biodiesel Blends on Wear of Mechanical Fuel Injection Equipment of a Constant Speed Diesel Engine, Renew. Energy, 2016, 99, p 1008–1018

S.H. Hamdan, W.W.F. Chong, J.-H. Ng, M.J. Ghazali, and R.J.K. Wood, Influence of Fatty Acid Methyl Ester Composition on Tribological Properties of vegetable Oils and Duck Fat Derived Biodiesel, Tribol. Int., 2017, 113, p 76–82

A.S.M. Handbook, Properties and Selection: Irons, Steels, and High-Performance Alloys, Vol 1, ASM International, Russell Township, 1990

Villares Metals, Catalog (2011). (http://www.villaresmetals.com.br). (http://www.villaresmetals.nl/english/files/Cat_SS.pdf).

J.F. Tovell, Ceramics and the Reciprocating Internal Combustion Engine, Mater. Des., 1984, 5, p 215–220

P.J. Blau, Friction and Wear of a Zr-Based Amorphous Metal Alloy Under Dry and Lubricated Conditions, Wear, 2001, 250, p 431–434

J. Qu, J.J. Truhan, and P.J. Blau, Investigation of the Scuffing Characteristics of Candidate Materials for Heavy Duty Diesel Fuel Injectors, Tribol. Int., 2005, 38, p 381–390

J. Qu, J.J. Truhan, P.J. Blau, and H.M. Meyer, III, Scuffing Transition Diagrams for Heavy Duty Diesel Fuel Injector Materials in Ultra Low-Sulfur Fuel-Lubricated Environment, Wear, 2005, 259, p 1031–1040

F. Gustavsson, P. Forsberg, and S. Jacobson, Friction and Wear Behavior of Low-Friction Coatings in Conventional and Alternative Fuels, Tribol. Int., 2012, 48, p 22–28

V.V. Castro, L.A.M. Fontoura, J.D. Benfica, M. Seferin, J.L. Pacheco, and C.A. Santos, Lubricated Sliding Wear of SAE 1045 and SAE 52100 Steel Against Alumina in the Presence of Biodiesel, Diesel and a 50:50 Blend of those Fuels, Wear, 2016, 368–369, p 267–277

ASTM E3–11, Standard Guide for Preparation of Metallographic Specimens, American Society for Testing and Materials, ASM Society, Russell Township p, 2011, p 8

ASTM E 18-03, Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials, American Society for Testing and Materials, ASM Society, Russell Township, 2004, p 22

ASTM E384-99, Standard Test Method for Microindentation Hardness of Materials, American Society for Testing and Materials, ASM Society, Russell Township, 2000, p 24

ASTM G99-04, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, American Society for Testing and Materials, ASM Society, Russell Township, 2004, p 5

M. Hua, X. Wei, and J. Li, Friction and Wear Behavior of SUS 304 Austenitic Stainless Steel Against Al2O3 Ceramic Ball Under Relative High Load, Wear, 2008, 265, p 799–810

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

J.F. Archard and W. Hirst, The Wear of metals Under Unlubricated Conditions, Proceed. R. Soc., 1956, 236–1206, p 397–410

J.K. Lancaster, Material-Specific Wear Mechanism: Relevance to Wear Modelling, Wear, 1990, 141, p 159–183

EN 14103, Fats and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Ester and Linolenic Acid Methyl Esters Contents, European Standard, European Committee for Standardization, Belgium, 2003, p 18

ASTM D 7371-12, Standard Test Method for Determination of Biodiesel (Fatty Acid Methyl Esters) Content in Diesel Fuel Oil Using Mid Infrared Spectroscopy (FTIRATR- PLS Method), American Society for Testing and Materials, ASM Society, Russell Township, 2012, p 10

K.H. Lo, F.T. Cheng, and H.C. Man, Laser Transformation Hardening of AISI, 440C Martensitic Stainless Steel for Higher Cavitation Erosion Resistance, Surf. Coat. Technol., 2003, 173(1), p 96–104

E. Huttunen-Saarivista, L. Kilpi, T.J. Hakala, L. Carpen, and H. Ronkainen, Tribocorrosion Study of Martensitic and Austenitic Stainless Steels in 0.01 M NaCl Solution, Tribol. Int., 2016, 95, p 358–371

R. Puli and G.D.J. Ram, Microstructures and Properties of Friction Surface Coatings in AISI, 440C Martensitic Stainless Steel, Surf. Coat. Technol., 2012, 207, p 310–318

H.H. Shen, L. Liu, X.Z. Liu, Q. Guo, T.X. Meng, Z.X. Wang, H.J. Yang, and X.P. Liu, Zr/ZrC Modified Layer Formed on AISI, 440B Stainless Steel by Plasma Zr-Alloying, Appl. Surf. Sci., 2016, 388, p 126–132

T.X. Meng, Q. Guo, W. Xi, W.Q. Ding, X.Z. Liu, N.M. Lin, S.W. Yu, and X.P. Liu, Effect of Surface Etching on the Oxidation Behavior of Plasma Chromizing-Treated AISI, 440B Stainless Steel, Appl. Surf. Sci., 2018, 433, p 855–861

V. Goyal, S.K. Sharma, and B.V.M. Kumar, Effect of Lubrication on Tribological Behaviour of Martensitic Stainless Steel, Mater. Today: Proceed., 2015, 2(4-5), p 1082–1091

Acknowledgments

The authors are grateful to the CNPq (The Brazilian Research Council—Grant Number: 403303/2016-8), FAPERGS (State Foundation for Research of Rio Grande do Sul), CAPES (Coordination for the Improvement of Higher Educational Personnel), and FINEP (Studies and Projects Financing Agency), for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Venske, A.F., de Castro, V.V., da Costa, E.M. et al. Sliding Wear Behavior of an AISI 440B Martensitic Stainless Steel Lubricated with Biodiesel and Diesel–Biodiesel Blends. J. of Materi Eng and Perform 27, 5427–5437 (2018). https://doi.org/10.1007/s11665-018-3626-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3626-x