Abstract

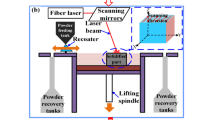

This paper deals with the influence of laser surface texturing on tribological performance of two different tool steels: (a) Böhler K100 produced by conventional production technology and (b) Böhler K390 Microclean® produced by powder metallurgy. The surface of heat-treated tool steels was modified using three different texture patterns. Impact of laser surface texturing was analyzed after different treatments. Furthermore, selected samples were borided to evaluate the combined influence of laser surface texturing and boriding on tribological performance of surface-treated samples. The results show that boriding was not beneficial for wavy surface type, and the steel production technology had a certain influence on the spinning tool. The laser surface texturing had an effect on decreasing the coefficient of friction on the K100 tool steel; however, it did not influence the tribological performance of the K390 Microclean® tool steel. Boriding process was efficient in decreasing the coefficient of friction for both steels. The low coefficient of friction values did not have a positive influence on the wear depth.

Similar content being viewed by others

References

LIGHTMOTIF, 2016. Texturing, https://www.lightmotif.nl/texturing/, 2017. Accessed 15 Dec 2017

R. Bathe, V.S. Krishna, S.K. Nikumb, and G. Padmanabham, Laser Surface Texturing of Gray Cast Iron for Improving Tribological Behaviour, Appl. Phys. A, 2014, 117, p 117. https://doi.org/10.1007/s00339-014-8281-y

E.T. Akinlabi, R.M. Mahamood, and S.A. Akinlabi, Advanced Manufacturing Techniques Using Laser Material Processing. IGI Global, 2016. 288 p. ISBN 978-15-225-0330-9

B. Bhushan and B.K. Bharat, Handbook of tribology. New York: McGraw-Hill, 1997, 1949 p. ISBN 1-57524-050-5

I. Etsion, Improving Tribological Performance of Mechanical Components by Laser Surface Texturing, Tribol. Lett., 2004, 17, p 733. https://doi.org/10.1007/s11249-004-8081-1

Z. Wang, Y.-B. Li, F. Bai, Ch-W Wang, and Q.-Z. Zhao, Angle-Dependent Lubricated Tribological Properties of Stainless Steel by Femtosecond Laser Surface Texturing, Opt. Laser Technol., 2016, 81, p 60–66. https://doi.org/10.1016/j.optlastec.2016.01.034

Z.P. Li, J.H. Wu, N. Wu, and D.X. Li, Experimental Study on Tribological Properties of Laser Textured 45 Steel Surface, in MATEC Web Conf. Volume 63, 2016. International Conference on Mechatronics, Manufacturing and Materials Engineering (MMME 2016). https://doi.org/10.1051/matecconf/20166302022

D. Liu, Q. Zhang, Z. Qin, Q. Luo, Z. Wu, and L. Liu, Tribological Performance of Surfaces Enhanced by Texturing and Nitrogen Implantation, Appl. Surf. Sci., 2016, 363, p 161–167. https://doi.org/10.1016/j.apsusc.2015.11.245

X. He, L.Z. Hong, G. Wang, Y. Liao, and Q. Liu, Tribological Behavior of Femtosecond Laser Textured Surfaces of 20CrNiMo/Beryllium Bronze Tribo-Pairs, Ind. Lubric. Tribol., 2015, 67(6), p 630–638

S. Kamboj, B. Atray, and N. Kumar, Analysis the Effects of Different Types of Tool on Metal Spinning Process. Int. J. Res. Eng. Technol., Vol. 03, no 02, 2014. e-ISSN: 2319-1163 | p-ISSN: 2321–7308, p 64–70. https://ijret.org/cdn/vols/2014v03/i02/IJRET20140302012.pdf, 2017. Accessed 12 Dec 2017

P.R. Fletter, Metal Spinning. 1995. http://www.fdp.nu/mikelldevice/spinning.pdf, 2017. Accessed 12 Dec 2017

B.P. Bewlay, and D.U. Furrer, Spinning, Metalworking: Sheet Forming, S.L. Semiatin, E. Marquard, H. Lampman, C. Karcher, and B. Musgrove, Ed., ASM International, Novelty, 2006, p 367–374

A. Patidar and B.A. Modi, Development of a Novel Tool for Sheet Metal Spinning Operation. ELK Asia Pac. J. Spec. Issue. ISBN: 978-81-930411-8-5. http://www.elkjournals.com/microadmin/UploadFolder/817041-%20DEVELOPMENT-OF-A-NOVEL-TOOL-FOR-SHEET-METAL-SPINNING-OPERATION.pdf, 2017. Accessed 12 Dec 2017

M. Shinde, S. Jadhav, and J. Gurav, Metal Forming by Sheet Metal Spinning Enhancement of Mechanical Properties and Parameter of Metal Spinning. IJEDR, Vol. 2, no 2, 2014 ISSN: 2321-9939. p 1352–1357

W. Homberg, D. Hornjak, and C. Beerwald. Manufacturing of Complex Functional Graded Workpieces with the Friction—Spinning Process. Int. J. Mater. Form. (2010) Vol. 3 Suppl 1: p 943–946. https://doi.org/10.1007/s12289-010-0924-8.

A. Satpute, S. Shirbhate, R. Bomale, and A. Sharma, Design and Fabrication of Metal Spinning Components. Int. J. Res. Sci. Eng., Vol, 2, Special Issue: 1-ICRITE. March 2016. e-ISSN: 2394-8299, p-ISSN: 2394-8280. p 28–33

F. Klocke and Ch.M. Brummer, Laser-Assisted Metal Spinning of Challenging Materials, Procedia Eng., 2014, 81, p 2385–2390. https://doi.org/10.1016/j.proeng.2014.10.338

J. Šugárová, P. Šugár, and P. Zemko, Analysing the Properties of Surface Layers Generated by Sheet Metal Forming Operations. Research Papers, Faculty of Materials Science and Technology in Trnava, Slovak University of Technology in Bratislava. Vol. 18, Number 29. 2010. e-ISSN: 1338-0532, p-ISSN: 1336-1589. p 39–45. https://www.mtf.stuba.sk/docs/doc/casopis_Vedecke_prace/29/3_sugarova.pdf, 2017. Accessed 12 Dec 2017

R. Moravčík, Tool Steels of the Ledeburite Type. 1st ed. Dresden: IFW, 2013. 111 p. ISBN 978-3-9808314-4-4.

P. Grgač, R. Moravčík, M. Hudáková, and M. Béger, Vplyv štruktúrnej heterogenity na vlastnosti vysokolegovaných nástrojových ocelí. (Structure heterogeneity influence to properties of high-alloyed tool steels.) In 23. dny tepelného zpracování s mezinárodní účastí. (23rd International Conference on Heat Treatment). Conference proceedings 23.DTZ 2010. 23. - 25.11.2010, Jihlava, Czech Republic. 1. Edition. Čerčany: Asociace pro tepelné zpracování kovů, 2010, p. ISBN 978-80-904462-3-6. (in Slovak)

G. Hoyle, High Speed Steels. Butterworths & Co. (Publishers) Ltd, London, 1988. 222 p. ISBN 978-0-4081103-2-7

P. Jurči, M. Dománková, Ľ. Čaplovič, J. Ptačinová, J. Sobotová, P. Salabová, O. Prikner, B. Šuštaršič, and D. Jenko, Microstructure and hardness of sub-zero treated and no tempered P/M Vanadis 6 ledeburitic tool steel, Vacuum, 2015, Vol. 111, p 92–101. ISSN 0042-207X. https://doi.org/10.1016/j.vacuum.2014.10.004

R. Moravčík and M. Hazlinger, Degradation Processes and Life-Time prediction. Editor: Aleš Čeněk, Plzeň, Czech Republic. 2017. 310 p. ISBN 978-80-7380-670-5.

J.R. Davis, Surface Engineering for Corrosion and Wear Resistance. ASM International, 2001. 257 p. ISBN 978-16-1503-072-9

Y. Su, L. Tian, R. Hu et al., Effect of Sputtering Current on the Comprehensive Properties of (Ti,Al)N Coating and High-Speed Steel Substrate. J. Mater. Eng. Perform. (2018) 27: p 2381. ISSN 1059-9495. https://doi.org/10.1007/s11665-018-3314-x

M. Haršáni, M. Sahul, P. Zacková, and Ľ. Čaplovič, Study of cathode current effect on the properties of CrAlSiN coatings prepared by LARC, Vacuum, 2017, Vol. 139, p 1–8. ISSN 0042-207X. https://doi.org/10.1016/j.vacuum.2017.01.029

J. Ptačinová, M. Drienovský, M. Palcut, R. Čička, M. Kusý, and M. Hudáková, Oxidation stability of boride coatings. Metallic Materials, 2016, 3(53), p 175–186. ISSN 1338-4252. https://doi.org/10.4149/km.2015.3.175

A. Dunn, K.L. Wlodarczyka, J.V. Carstensenb, E.B. Hansenb, J. Gabzdylc, P.M. Harrisonc, J.D. Shepharda, and D.P. Hand, Laser Surface Texturing for High Friction Contacts, Appl. Surf. Sci., 2015, 357, p 2313–2319. https://doi.org/10.1016/j.apsusc.2015.09.233

I. Etsion, State of the Art in Laser Surface Texturing, J. Tribol. Trans. ASME, 2005, 127, p 248–253. https://doi.org/10.1115/1.1828070

M. Bonek, Formation of Hard Composite Layer on Tool Steel by Laser Alloying, Arch. Metall. Mater., 2016, 61(2), p 719–724

M. Bonek, The Investigation of Microstructures and Properties of High Speed Steel HS6-5-2-5 After Laser Alloying, Arch. Metall. Mater., 2014, 59(4), p 1659–1663

L.A. Dobrzański, T. Tański, A.D. Dobrzańska-Danikiewicz, E. Jonda, M. Bonek, and A. Drygała, Structures, Properties and Development Trends of Laser Surface Treated Hot-Work Steels, Light Metal Alloys and Polycrystalline Silicon, Laser Surface Engineering. Processes and Applications, J. Lawrence and D. Waugh, Ed., Woodhead Publishing Series in Electronic and Optical Materials, Amsterdam, 2015, p 3–32

W. Zhao, G.C. Zha, M.Z. Xi et al., Effects of Synchronous Rolling on Microstructure, Hardness, and Wear Resistance of Laser Multilayer Cladding, J. Mater. Eng. Perform., 2018, 27, p 1746. ISSN 1059-9495. https://doi.org/10.1007/s11665-018-3286-x

M. Mathapati, M. Doddamani, and M.R. Ramesh, High-Temperature Erosive Behavior of Plasma Sprayed Cr3C2-NiCr/Cenosphere Coating, J. Mater. Eng. Perform., 2018, 27, p 1592. ISSN 1059-9495. https://doi.org/10.1007/s11665-018-3226-9

D. Lou, D. Liu, C. He et al., Effect of Cr/C Ratio on Microstructure and Corrosion Performance of Cr3C2-NiCr Composite Fabricated by Laser Processing. J. Mater. Eng. Perform. (2016) 25: p 312. ISSN 1059-9495. https://doi.org/10.1007/s11665-015-1843-0

Kaltarbeitsstahl – Cold Work Tool Steel, Böhler K100, Böhler, 2010. http://www.bohler.de/media/productdb/downloads/K100DE.pdf, 2017. Accessed 12 Dec 2017

Kaltarbeitsstahl – Cold Work Tool Steel, Böhler K390 Microclean®, Böhler, 2014. http://www.bohler-edelstahl.com/media/productdb/downloads/K390DE.pdf, 2017. Accessed 12 Dec 2017

Hertzian Contact Stress Calculator. http://www.amesweb.info/HertzianContact/HertzianContact.aspx, 2017. Accessed 12 Dec 2017

ASM HANDBOOK (Book 4). ASM International; 10 edition (December 1, 1991). 1012 p. ISBN 978-0871703798

J. Lubas, Tribological Characteristics of the Surface Layer of Steel Modified with Boron under Mixed Friction Conditions. J. KONES Powertrain Transp., Vol. 18, no. 2, 2011. ISSN: 1231-4005, E-ISSN: 2354-0133

E.E.V. Cárdenas, R. Lewis, A. I.M. Pérez, J.L.B. Ponce, F.J.P. Pinal, M.O. Domínguez, and E.D.R. Arreola, Characterization and wear performance of boride phases over tool steel substrates, Adv. Mech. Eng., February 5, 2016, Vol. 8(2). ISSN: 1687-8140, p 1–10. https://doi.org/10.1177/1687814016630257

Acknowledgments

This contribution/publication is the result of the project implementation: Centre of Excellence for development and application of advanced diagnostic methods in processing of metallic and nonmetallic materials—APRODIMET, ITMS: 26220120048, supported by the Research and Development Operational Programme funded by the ERDF. This study was also supported by the Grant agency of the Ministry of Education of the Slovak Republic and the Slovak academy of Sciences (VEGA) under the contract numbers 1/0876/15 (Preparation and characterization of the properties of new types of hard coatings for tool materials) and 1/0669/15 (Research of laser surface texturing and its application in the sheet metal forming processes tribological conditions optimization). The authors would also like to thank the staff at the research laboratory Promatech at the Institute of Materials Research of Slovak Academy of Science in Košice, for help with the execution of tribological experiments. Dr. Marián Palcut is acknowledged for his useful comments and proofreading of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moravčíková, J., Moravčík, R., Kusý, M. et al. Influence of Laser Surface Texturing on Tribological Performance of Tool Steels. J. of Materi Eng and Perform 27, 5417–5426 (2018). https://doi.org/10.1007/s11665-018-3607-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3607-0