Abstract

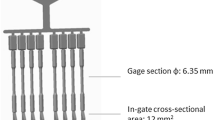

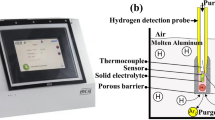

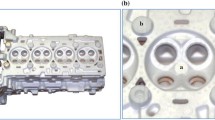

In most of the practical casting operations, it is important to be able to cast large number of part with one single melt. Therefore, when quantity of the charge and melting crucible is increased, during casting process, the liquid is led to settle for a long period of time. In this work, 10 kg charge of A356 was melted at 750 °C and held for 240 min. A sand mold with different thickness was cast at 30, 60, 120, and 240 min of holding time of the liquid, before and after degassing conditions. Melt quality was measured by reduced pressure test, and pore size and number were measured at each cast part. A correlation between bifilm index and tensile properties was established. It was found that melt quality was decreased with increased holding time and pore formation was enhanced linearly. Additionally, mechanical properties of the alloy were decreased with decreased melt quality and increased pore formation due to holding time of the liquid.

Similar content being viewed by others

References

J. Campbell, Castings, Vol Second, Butterworth-Heinemann, London, 2003

Y.-C. Tsai, C.-Y. Chou, S.-L. Lee, C.-K. Lin, J.-C. Lin, and S. Lims, Effect of Trace La Addition on the Microstructures and Mechanical Properties of A356 (Al-7Si-0.35Mg) Aluminum Alloys, J. Alloys Compd., 2009, 487(1), p 157–162

F. Mao, G. Yan, Z. Xuan, Z. Cao, and T. Wang, Effect of Eu Addition on the Microstructures and Mechanical Properties of A356 Aluminum Alloys, J. Alloys Compd., 2015, 650, p 896–906

P.R. Guru, F. Md Khan, S.K. Panigrahi, and G.D.J. Rams, Enhancing Strength, Ductility and Machinability of a Al-Si Cast Alloy by Friction Stir Processing, J. Manuf. Process., 2015, 18(Supplement C), p 67–74

E.A.-D. la Torre, R. Pérez-Bustamante, J. Camarillo-Cisneros, C.D. Gómez-Esparza, H.M. Medrano-Prieto, and R. Martínez-Sánchezs, Mechanical Properties of the A356 Aluminum Alloy Modified with La/Ce, J. Rare Earths, 2013, 31(8), p 811–816

J.G. Conley, J. Huang, J. Asada, and K. Akibas, Modeling the Effects of Cooling Rate, Hydrogen Content, Grain Refiner and Modifier on Microporosity Formation in Al A356 Alloys, Mater. Sci. Eng., A, 2000, 285(1), p 49–55

J.S. Major, Porosity Control and Fatigue Behavior in A356-T61 Aluminum Alloy, Trans.Am. Foundrym. Soc., 1998, 97, p 901–906

I.S. Polmear, Light alloys 3rd ed. Metallurgy of the Light Metals, Edward Arnold, London, 1995, p 231–232

M. Seniw, M. Fine, E. Chen, M. Meshii, and J. Gray, Relation of Defect Size and Location to Fatigue Failure in Al Alloy A356 Cast Specimens, The Minerals, Metals and Materials Society, Warrendale, 1997

S. Farahany, A. Ourdjini, and H.R. Bakhsheshi-Rads, Microstructure, Mechanical Properties and Corrosion Behavior of Al-Si-Cu-Zn-X (X = Bi, Sb, Sr) Die Cast Alloy, Trans. Nonferrous Met. Soc. China, 2016, 26(1), p 28–38

S. Singh, D. Patel, P. Ansari, D. kumar Jadhav, C. Verma, and J. Menghanis, Effect of Grain refinement, Modifier and Stirring on Properties of A356, Mater Today Proc, 2017, 4(2, Part A), p 734–739

R.J. Immanuel and S.K. Panigrahis, Transformation of Cast A356 İngots to Wrought Sheets with Enhanced Mechanical and Tribological Properties by Different Thermo-Mechanical Processing Routes, Mater. Des., 2016, 101(Supplement C), p 44–55

B. Jung, C. Jung, T. Han, and Y. Kims, Electromagnetic Stirring and Sr Modification in A356 Alloy, J. Mater. Process. Technol., 2001, 111(1), p 69–73

M. De Giovanni, J.M. Warnett, M.A. Williams, and P. Srirangams, 3D İmaging and Quantification of Porosity and İntermetallic Particles in Strontium Modified Al-Si Alloys, J. Alloys Compd., 2017, 727(Supplement C), p 353–361

D. Emadi, J. Gruzleski, and J. Toguris, The Effect of Na and Sr Modification on Surface Tension and Volumetric Shrinkage of A356 Alloy and Their İnfluence on Porosity Formation, Metall. Mater. Trans. B, 1993, 24(6), p 1055–1063

H. Xu, X. Jian, T.T. Meek, and Q. Hans, Degassing of Molten Aluminum A356 Alloy Using Ultrasonic Vibration, Mater. Lett., 2004, 58(29), p 3669–3673

J.Y. Buffière, S. Savelli, P.H. Jouneau, E. Maire, and R. Fougèress, EXPERİMENTAL Study of Porosity and its Relation to Fatigue Mechanisms of model Al-Si7-Mg0.3 Cast Al Alloys, Mater. Sci. Eng. A, 2001, 316(1), p 115–126

D. Dispinar, S. Akhtar, A. Nordmark, M. Di Sabatino, and L. Arnbergs, Degassing, Hydrogen and Porosity Phenomena in A356, Mater. Sci. Eng., A, 2010, 527(16), p 3719–3725

D. Dispinar and J. Campbells, Critical Assessment of Reduced Pressure Test. Part 1: Porosity Phenomena, Int. J. Cast Met. Res., 2004, 17(5), p 280–286

D. Dispinar and J. Campbells, Critical Assessment of Reduced Pressure Test. Part 2: Quantification, Int. J. Cast Met. Res., 2004, 17(5), p 287–294

D. Dispinar and J. Campbells, Porosity, Hydrogen and Bifilm Content in Al Alloy Castings, Mater. Sci. Eng., A, 2011, 528(10), p 3860–3865

M. Mostafaei, M. Ghobadi, M. Uludağ, and M. Tiryakioğlus, Evaluation of the Effects of Rotary Degassing Process Variables on the Quality of A357 Aluminum Alloy Castings, Metall. Mater. Trans. B, 2016, 47(6), p 3469–3475

D.G. Eskin, K. Al-Helal, and I. Tzanakiss, Application of a Plate Sonotrode to Ultrasonic Degassing of Aluminum Melt: Acoustic Measurements and Feasibility Study, J. Mater. Process. Technol., 2015, 222(Supplement C), p 148–154

H. Puga, J. Barbosa, N.Q. Tuan, and F. Silvas, Effect of Ultrasonic Degassing on Performance of Al-Based Components, Trans. Nonferrous Met. Soc. China, 2014, 24(11), p 3459–3464

M. Uludağ, R. Çetin, D. Dispinar, and M. Tiryakioğlus, Characterization of the Effect of Melt Treatments on Melt Quality in Al-7wt% Si-Mg Alloys, Metals, 2017, 7(5), p 157

J. Runyoro, S. Boutorabi, and J. Campbells, Critical Gate Velocities for Film-Forming Casting Alloys: A Basis for Process Specification, AFS Trans, 1992, 100, p 225–234

M. Rezvani, X. Yang, and J. Campbells, Effect of Ingate Design on Strength and Reliability of Al Castings (99-33), Trans. Am. Foundrym. Soc., 1999, 107, p 181–188

N. Green and J. Campbells, Influence of Oxide Film Filling Defects on the Strength of Al-7Si-Mg Alloy Castings (94-114), Trans. Am. Foundrym. Soc., 1994, 102, p 341–348

C. Nyahumwa, N. Green, and J. Campbells, Effect of Mold-Filling Turbulence on Fatigue Properties of Cast Aluminum Alloys (98-58), Trans. Am. Foundrym. Soc., 1998, 106, p 215–224

B.G. Eisaabadi, P. Davami, SK Kim, and M. Tiryakioğlus, The Effect of Melt Quality and Filtering on the Weibull Distributions of Tensile Properties in Al-7%Si-Mg Alloy Castings, Mater. Sci. Eng., A, 2013, 579, p 64–70

G. Eisaabadi Bozchaloei, N. Varahram, P. Davami, and S.K. Kims, Effect of Oxide Bifilms on the Mechanical Properties of Cast Al-7Si-0.3Mg alloy and the Roll of Runner Height After Filter on Their Formation, Mater. Sci. Eng. A, 2012, 548, p 99–105

X. Dai, X. Yang, J. Campbell, and J. Woods, Influence of Oxide Film Defects Generated in Filling on Mechanical Strength of Aluminium Alloy Castings, Mater. Sci. Technol., 2004, 20(4), p 505–513

M. Asadian Nozari, R. Taghiabadi, M. Karimzadeh, and M.H. Ghonchehs, Investigation on Beneficial Effects of Beryllium on Entrained Oxide Films, Mechanical Properties and Casting Reliability of Fe-Rich Al-Si Cast Alloy, Mater. Sci. Technol., 2015, 31(4), p 506–512

G. Timelli, O. Lohne, L. Arnberg, and H.I. Lauklis, Effect of Solution Heat Treatments on the Microstructure and Mechanical Properties of a Die-Cast AlSi7MgMn Alloy, Metall. Mater. Trans. A, 2008, 39(7), p 1747

X. Cao and J. Campbells, Precipitation of Primary İntermetallic Compounds in Liquid Al 11.5 Si 0.4 Mg Alloy, Int. J. Cast Met. Res., 2000, 13(3), p 175–184

X. Cao and J. Campbells, The Nucleation of Fe-rich Phases on Oxide Films in Al-11.5 Si-0.4 Mg Cast Alloys, Metall. Mater. Trans. A, 2003, 34(7), p 1409–1420

X. Cao and J. Campbells, The Solidification Characteristics of Fe-Rich İntermetallics in Al-11.5 Si-0.4 Mg Cast Alloys, Metall. Mater. Trans. A, 2004, 35(5), p 1425–1435

K. Liu, X.-J. Cao, and X.-G. Chens, Solidification of İron-Rich İntermetallic Phases in Al-4.5 Cu-0.3 Fe Cast Alloy, Metall. Mater. Trans. A, 2011, 42(7), p 2004–2016

K. Liu, X.-J. Cao, and X.-G. Chens, Effect of Mn, Si, and Cooling Rate on the Formation of İron-Rich İntermetallics in 206 Al-Cu Cast Alloys, Metall. Mater. Trans. A, 2012, 43(5), p 1231–1240

J.S. Campbell, An Overview of the Effects of Bifilms on the Structure and Properties of Cast Alloys, Metall. Mater. Trans. B, 2006, 37(6), p 857–863

H. Mayer, M. Papakyriacou, B. Zettl, and S.E. Stanzl-Tscheggs, Influence of Porosity on the Fatigue Limit of Die Cast Magnesium and Aluminium Alloys, Int. J. Fatigue, 2003, 25(3), p 245–256

N. Read, W. Wang, K. Essa, and M.M. Attallahs, Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development. Mater. Des. (1980–2015), 2015, 6, p 417–424

T.S. Tunçay, in Difüzörlü Ve Difüzörsüz Yolluk Sistemlerinin A356 Alaşımının Mekanik Özelliklerine Etkisi. Gazi Üniversitesi Mühendislik-Mimarlık Fakültesi Dergisi, 2013, 28(2), p 241–249

M. Tiryakioğlu, J. Campbell, and N.D. Alexopouloss, On the Ductility of Cast Al-7 Pct Si-Mg Alloys, Metall. Mater. Trans. A, 2009, 40(4), p 1000

D. Dispinar and J. Campbells, Use of Bifilm İndex as an Assessment of Liquid Metal Quality, Int. J. Cast Met. Res., 2006, 19(1), p 5–17

M. Uludağ, R. Çetin, D. Dişpinar, and M. Tiryakioğlus, On the Interpretation of Melt Quality Assessment of A356 Aluminum Alloy by the Reduced Pressure Test: The Bifilm Index and Its Physical Meaning. Int. J. Metalcast., 2018, https://doi.org/10.1007/s40962-018-0217-4

M. Uludağ, R. Çetin, D. Dispinar, and M. Tiryakioğlus, The Effects of Degassing, Grain Refinement & Sr-Addition on Melt Quality-Hot Tear Sensitivity Relationships in Cast A380 Aluminum Alloy, Eng. Fail. Anal., 2018, 90, p 90–102

X. Liu, C. Zhang, Z. Zhang, J. Xue, and Q. Les, The Role of Ultrasound in Hydrogen Removal and Microstructure Refinement by Ultrasonic Argon Degassing Process, Ultrason. Sonochem., 2017, 38, p 455–462

M.A. El-Sayed, I. Shyha, and F.H. Basunys, Effect of Hydrogen Content on the Double Oxide Film Defects and Properties of Aluminium Castings: A Review, J. Eng. Technol., 2018, 6, p 225–244

M. Uludağ, R. Çetin, and D. Dispinars, Freezing Range, Melt Quality, and Hot Tearing in Al-Si Alloys, Metall. Mater. Trans. A, 2018, 49(5), p 1948–1961

M. Uludağ and D. Dişpinars, Assessment of Mechanism of Pore Formation in Directionally Solidified A356 Alloy, Arch. Foundry Eng., 2017, 17(1), p 157–162

M. Uludağ, M. Kocabaş, D. Dışpınar, R. Çetin, and N. Cansevers, Effect of Sr and Ti Addition on the Corrosion Behaviour of Al-7Si-0.3 Mg Alloy, Arch. Foundry Eng., 2017, 17(2), p 125–130

M. Uludağ, L. Gemi, R. Çetin, and D. Dispinars, The Effect of Holding Time and Solidification Rate on Porosity of A356, Am. J. Eng. Res., 2016, 5(12), p 271–275

L. Li, D. Li, J. Gao, Y. Zhang, and Y. Kang, Influence of Mold Temperature on Microstructure and Shrinkage Porosity of the A357 Alloys in Gravity Die Casting, Springer, Berlin, 2018

T.S. Tunçay, The Effect of Modification and Grain Refining on the Microstructure and Mechanical Properties of A356 Alloy, Acta Phys. Pol. A, 2017, 131(1), p 89–91

A. Bahmani, G.B. Eisaabadi, P. Davami, N. Varahram, and M.O. Shabanis, Effects of Hydrogen Level and Cooling Rate on Ultimate Tensile Strength of Al A319 Alloy, Russ J. Non-Ferrous Met., 2014, 55(4), p 365–370

T. Tunçay, S. Tekeli, D. Özyürek, and D. Dişpinars, Microstructure–Bifilm İnteraction and İts Relation with Mechanical Properties in A356, Int. J. Cast Met. Res., 2017, 30(1), p 20–29

T. Ludwig, M. Di Sabatino, L. Arnberg, and D. Dispinars, Influence of Oxide Additions on the Porosity Development and Mechanical Properties of A356 Aluminium Alloy Castings, Int. J. Metalcast., 2012, 6(2), p 41–50

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uludağ, M., Çetin, R., Gemi, L. et al. Change in Porosity of A356 by Holding Time and Its Effect on Mechanical Properties. J. of Materi Eng and Perform 27, 5141–5151 (2018). https://doi.org/10.1007/s11665-018-3534-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3534-0