Abstract

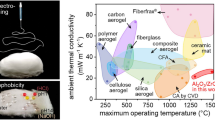

This paper concerns the thermophysical properties of high-frequency induction heat (HFIH) sintered alumina ceramic nanocomposites containing various graphene nanoplatelets (GNP) concentrations. The GNP/alumina nanocomposites demonstrated high densities, fine-grained microstructures, highest fracture toughness and hardness values of 5.7 MPa m1/2 and 18.4 GPa, which found 72 and 8%, superior to the benchmarked monolithic alumina, respectively. We determine the role of GNP in tuning the microstructure and inducing toughening mechanisms in the nanocomposites. The sintered monolithic alumina exhibited thermal conductivity value of 24.8 W/mK; however, steady drops of 2, 15 and 19% were recorded after adding respective GNP contents of 0.25, 0.5 and 1.0 wt.% in the nanocomposites. In addition, a dwindling trend in thermal conductions with increasing temperatures was recorded for all sintered samples. Simulation of experimental results with proven theoretical thermal models showed the dominant role of GNP dispersions, microstructural porosity, elastic modulus and grain size in controlling the thermal transport properties of the GNP/alumina nanocomposites. Thermogravimetric analysis showed that the nanocomposite with up to 0.5 mass% of GNP is thermally stable at the temperatures greater than 875 °C. The GNP/alumina nanocomposites owning a distinctive combination of mechanical and thermal properties are promising contenders for the specific components of the aerospace engine and electronic devices having contact with elevated temperatures.

Similar content being viewed by others

References

D. Faoite, D. Browne, R. Franklin, and T. Kenneth Stanton, A Review of the Processing, Composition, and Temperature-Dependent Mechanical and Thermal Properties of Dielectric Technical Ceramics, J. Mater. Sci., 2012, 47, p 4211–4235

K. Ahmad, P. Wei, and C. Wan, Thermal Conductivities of Alumina-Based Multiwall Carbon Nanotube Ceramic Composites, J. Mater. Sci., 2014, 49, p 6048–6055

S.R. Bakshi, K. Balani, and A. Agarwal, Thermal Conductivity of Plasma-Sprayed Aluminum Oxide—Multiwalled Carbon Nanotubes Composites, J. Am. Ceram. Soc., 2008, 91, p 942–947

L. Kumari and T. Zhang, Thermal Properties of CNT Alumina Nanocomposites, Compos. Sci. Technol., 2008, 68, p 2178–2183

H. Porwal, S. Grasso, and M. Reece, Review of Graphene–Ceramic Matrix Composites, Adv. Appl. Ceram., 2013, 112, p 443–454

Y. Fan, The Effect of Homogeneously Dispersed Few-Layer Graphene on Microstructure and Mechanical Properties of Al2O3 Nanocomposites, J. Eur. Ceram. Soc., 2014, 34, p 443–451

I. Ahmad and Y.Q. Zhu, Recent Advances on Carbon Nanotubes and Graphene Reinforced Ceramics Nanocomposites, Nanomaterials, 2015, 5, p 90–114

K. Wang, Preparation of Graphene Nanosheets/Alumina Composites by Spark Plasma Sintering, Mater. Res. Bull., 2011, 46, p 315–318

L. Jain, Mechanical Properties of Graphene Platelets-Reinforced Alumina Ceramics Composites, Ceram. Int., 2013, 39, p 6215–6221

H. Porwal, Graphene Reinforced Alumina Nano-composites, Carbon, 2013, 64, p 359–369

C. Balázsi, Structural Characterization of Si3N4-Carbon Nanotube Interfaces by Transmission Electron Microscopy, Compos. Sci. Technol., 2008, 68, p 1596–1599

I. Ahmad, M. Islam, T. Subhani, and Y.Q. Zhu, Toughening Mechanisms and Mechanical Properties of Graphene Nanosheet-Reinforced Alumina, Mater. Des., 2015, 88, p 1234–1243

A.A. Balandin, Thermal Properties of Graphene and Nanostructured Carbon Materials, Nat. Mater., 2011, 10, p 569–581

A.C. Ferrari, J.C. Meyer, V. Scardaci, C. Casiraghi, M. Lazzeri, F. Mauri, S. Piscanec, D. Jiang, K.S. Novoselov, S. Roth, and A.K. Geim, Raman Spectrum of Graphene and Graphene Layers, Phys. Rev. Lett., 2006, 97, p 187401

I. Calizo, A.A. Balandin, W. Bao, F. Miao, and C.N. Lau, Temperature Dependence of the Raman Spectra of Graphene and Graphene Multilayers, Nano Lett., 2007, 7, p 2645

M.F. Khan and A.A. Balandin, Thermal Properties of Graphene and Multilayer Graphene: Applications in Thermal Interface Materials, Solid State Commun., 2012, 152, p 1331–1340

I. Ahmad, M. Islam, T. Subhani, and Y.Q. Zhu, Characterization of GNP-Containing Al2O3 Nanocomposites Fabricated via High Frequency-Induction Heat Sintering Route, J. Mater. Eng. Perform., 2015, 24, p 4236–4243

X. Liu, Y. Fan, J. Li, L. Wang, and W. Jiang, Preparation and Mechanical Properties of Graphene Nanosheet Reinforced Alumina Composites, Adv. Eng. Mater., 2015, 17, p 28–35

K. Tonello, E. Padovano, C. Badini, S. Biamino, M. Pavese, and P. Fino, Fabrication and Characterization of Laminated SiC Composites Reinforced with Graphene Nanoplatelets, Mater. Sci. Eng., 2016, 659, p 158–164

M. Belmonte, A. Nistal, P. Boutbien, B. Román-Manso, M.I. Osendi, and P. Miranzo, Toughened and Strengthened Silicon Carbide Ceramics by Adding Graphene-Based Fillers, Scr. Mater., 2016, 113, p 127–130

B. Román-Manso, E. Domingues, F.M. Figueiredo, M. Belmonte, and P. Miranzo, Enhanced Electrical Conductivity of Silicon Carbide Ceramics by Addition of Graphene Nanoplatelets, J. Eur. Ceram. Soc., 2015, 35, p 2723–2731

Q. Li, Y. Zhang, H. Gong, H. Sun, T. Li, X. Guo, and S. Ai, Effects of Graphene on the Thermal Conductivity of Pressureless-Sintered SiC Ceramics, Ceram. Int., 2015, 41, p p13547–p13552

L.S. Walker, V.R. Marotto, M.A. Rafiee, N. Koratkar, and E.L. Corral, Toughening in Graphene Ceramic Composites, ACS Nano, 2011, 5, p 3182–3190

P. Kun, O. Tapasztó, F. Wéber, and C. Balázsi, Determination of Structural and Mechanical Properties of Multilayer Graphene Added Silicon Nitride-Based Composites, Ceram. Int., 2012, 38, p 211–216

Y. Çelik, A. Çelik, E. Flahaut, and E. Suvaci, Anisotropic Mechanical and Functional Properties of Graphene-Based Alumina Matrix Nanocomposites, J. Eur. Ceram. Soc., 2016, 36, p 2075–2086

P. Rutkowski, W. Piekarczyk, L. Stobierski, and G. Górny, Anisotropy of Elastic Properties and Thermal Conductivity of Al2O3/h-BN Composites, J. Therm. Anal. Calorim., 2013, 115, p 461–466

P. Rutkowski, L. Stobierski, and G. Górny, Thermal Stability and Conductivity of Hot-Pressed Si3N4–Graphene Composites, J. Therm. Anal. Calorim., 2014, 116, p 321–328

I. Ahmad, M. Islam, T. Subhani, and Y.Q. Zhu, Toughness Enhancement in Graphene Nanoplatelet/SiC Reinforced Al2O3 Ceramic Hybrid Nanocomposites, Nanotechnology, 2016, 27, p 42

S.W. Kim and A.R. Khalil, High-Frequency Induction Heat Sintering of Mechanically Alloyed Alumina–Yttria-Stabilized Zirconia Nano-bioceramics, J. Am. Ceram. Soc., 2006, 89, p 1280–1285

W.S. Hummers and R.E. Offeman, Preparation of Graphitic Oxide, J. Am. Chem. Soc. , 1958, 80, p 1339–1340

I. Barin, Thermochemical Data of Pure Substances, VCH, Weinheim, 1993

N. Takeshi and I. Tadao, Temperature Dependence of Lattice Vibrations and Analysis of the Specific Heat of Graphite, Phys. Rev., 2003, 68, p 399–404

A. Lerf, H. He, M. Forster, and J. Klinowski, Structure of Graphite Oxide Revisited, J. Phys. Chem., 1998, 102, p 4477–4482

H.C. Schniepp, J.L. Li, M.J. McAllister, H. Sai, M. Herrera-Alonso, D.H. Adamson, and I.A. Aksay, Functionalized Single Graphene Sheets Derived from Splitting Graphite Oxide, J. Phys. Chem., 2006, 110, p 8535–8539

H.C. Hsu and W.H. Tuan, Thermal Characteristics of a Two-Phase Composite, Adv. Powder Technol., 2016, 27, p 929–934

M.F. Ashby, Criteria for Selecting the Components of Composites, Acta Metall. Mater., 1993, 41, p 1313–1335

J.D. Renteria, S. Ramirez, H. Malekpour, B. Alonso, A. Centeno, and A. Zurutuza, Anisotropy of Thermal Conductivity of Free-Standing Reduced Graphene Oxide Films Annealed at High Temperature, Adv. Funct. Mater., 2015, 25, p 4664–4672

H. Ondrej, S. Jaroslav, H. Eva, and S. Pavol, Thermal Properties of Alumina–MWCNTs Composites, J. Am. Eur. Ceram. Soc., 2015, 35, p 1559–1567

E. Çelik and A.K. Roy, Thermal Properties of Graphene: Fundamentals and Applications, MRS Bull., 2012, 37, p 1273–1281

S.R. Wang, M. Tambraparni, J.J. Qiu, J. Tipton, and D. Dean, Thermal Expansion of Graphene Composites, Macromolecules, 2009, 42, p 5251–5255

N.J. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, 173, p 25–28

C.J. Lin, I.C. Lin, and W.H. Tuan, Effect of Graphene Concentration on Thermal Properties of Alumina–Graphene Composites Formed Using Spark Plasma Sintering, J. Mater. Sci., 2017, 52, p 1759–1766

K.W. Schlichting, N.P. Padture, and P.G. Klemens, Thermal Conductivity of Dense and Porous Yttria-Stabilized Zirconia, J. Mater. Sci., 2001, 36, p 3003–3010

B.K. Jang and Y. Sakka, Influence of Microstructure on the Thermophysical Properties of Sintered SiC Ceramics, J. Alloys. Compd., 2008, 463, p 493–497

D.R. Clarke, Materials Selection Guidelines for Low Thermal Conductivity Thermal Barrier Coatings, Surf. Coat. Technol., 2003, 163, p 67–74

S.C. Zhang, W.G. Fahrenholtz, G.E. Hilmas, and E.J. Yadlowsky, Pressureless Sintering of Carbon Nanotube-Al2O3 Composites, J. Eur. Ceram. Soc., 2010, 30, p 33–35

Acknowledgments

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for funding this Research Group Project No. RG-1437-028.

Conflict of Interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmad, I., Subhani, T., Wang, N. et al. Thermophysical Properties of High-Frequency Induction Heat Sintered Graphene Nanoplatelets/Alumina Ceramic Functional Nanocomposites. J. of Materi Eng and Perform 27, 2949–2959 (2018). https://doi.org/10.1007/s11665-018-3395-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3395-6