Abstract

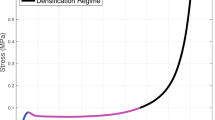

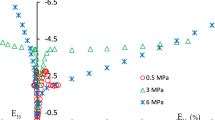

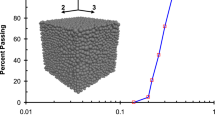

The prediction of the mechanical behavior of metallic foams with realistic microstructure and the effects of various boundary conditions on the mechanical behavior is an important and challenging issue in modeling representative volume elements (RVEs). A numerical investigation is conducted to determine the effects of various boundary conditions and cell wall cross sections on the compressive mechanical properties of aluminum foam, including the stiffness, plateau stress and onset strain of densification. The open-cell AA6101-T6 aluminum foam Duocel is used in the analyses in this study. Geometrical characteristics including the cell size, foam relative density, and cross-sectional shape and thickness of the cell walls are extracted from images of the foam. Then, the obtained foam microstructure is analyzed as a 2D model. The ligaments are modeled as shear deformable beams with elastic-plastic material behavior. To prevent interpenetration of the nodes and walls inside the cells with large deformations, self-contact-type frictionless interaction is stipulated between the internal surfaces. Sensitivity analyses are performed using several boundary conditions and cells wall cross-sectional shapes. The predicted results from the finite element analyses are compared with the experimental results. Finally, the most appropriate boundary conditions, leading to more consistent results with the experimental data, are introduced.

Similar content being viewed by others

References

C. Tekoglu and P.R. Onck, Size Effects in the Mechanical Behaviour of Cellular Materials, J. Mater. Sci., 2005, 40, p 5911–5917

M.F. Ashby, A.G. Evans, N.A. Fleck, and L.J. Gibson, Metal Foams: A Design Guide, 1st ed., Butterworth-Heinemann, Boston, 2000

I. Sridhar and N.A. Fleck, The Multiaxial Yield Behavior of an Aluminium Alloy Foam, J. Mater. Sci., 2005, 40, p 4005–4008

A. Reyes, O.S. Hopperstad, A.G. Hanssen, and M. Langseth, Modelling of Material Failure in Foam-Based Components, Int. J. Impact. Eng., 2004, 30, p 805–834

L. Maheo, Elastic Behaviour of Multi-Scale, Open-Cell Foams, Compos. Part B, 2013, 44, p 172–183

P. Degischer and B. Kriszt, Handbook of Cellular Metals: Production, Processing, Application, Wiley, New York, 2002

J. Gibson and F. Ashby, Cellular Solids: Structure and Properties, 2nd ed., Oxford shire press, Oxford, 1997

V.S. Deshpande and N.A. Fleck, Isotropic Constitutive Models for Metallic Foams, J. Mech. Phys. Solids, 2000, 48, p 1253–1283

P.R. Onck, Application of A Continuum Constitutive Model to Metallic Foam DEN-Specimens in Compression, Int. J. Mech. Sci., 2001, 43, p 2947–2959

Y. Kim and S. Kang, Development of Experimental Method to Characterize Pressure-Dependent Yield Criteria for Polymeric Foams, Polym. Test, 2003, 22, p 197–202

M. Ghayour, H. Hosseini-Toudeshky, M. Jalalvand, and E.J. Barbero, Micro/Macro Approach for Prediction of Matrix Cracking Evolution in Laminated Composites, J. Compos. Mater., 2015, 50, p 2647–2659

G. Sadeghi, H. Hosseini-Toudeshky, and B. Mohammadi, In-Plane Progressive Matrix Cracking Analysis of Symmetric Cross-Ply Laminates With Holes, Fatigue. Fract. Eng. M, 2014, 37, p 290–305

H. Hosseini-Toudeshky, A. Farrokhabadi, and B. Mohammadi, Implementation of a Micro-Meso Approach for Progressive Damage Analysis of Composite Laminates, Struct. Eng. Mech., 2012, 43, p 657–678

R.M. Christensen, Mechanics of Low Density Materials, J. Mech. Phys. Solids, 1986, 34, p 563–578

J.L. Grenestedt, Influence of Wavy Imperfections in Cell Walls on Elastic Stiffness of Cellular Solids, J. Mech. Phys. Solids, 1998, 46, p 29–50

W.E. Warren and A.M. Kraynik, Foam Mechanics: The Linear Elastic Response of Two-Dimensional Spatially Periodic Cellular Materials, Mech. Mater., 1987, 6, p 27–37

W.E. Warren and A.M. Kraynik, The Linear Elastic Properties of Open-Cell Foams, J. Appl. Mech., 1988, 55, p 341–346

W.E. Warren, A.M. Kraynik, and C.M. Stone, A Constitutive Model For Two-Dimensional Nonlinear Elastic Foams, J. Mech. Phys. Solids, 1989, 37, p 717–733

Y. Wang and A.M. Cuitino, Three-Dimensional Nonlinear Open-Cell Foams With Large Deformations, J. Mech. Phys. Solids, 2000, 48, p 961–988

H. Harders, K. Hupfer, and J. Rosler, Influence of Cell Wall Shape And Density on the Mechanical Behaviour of 2D Foam Structures, Acta Mater., 2005, 53, p 1335–1345

H.S. Kim and S.T.S. Al-Hassani, A Morphological Elastic Model of General Hexagonal Columnar Structures, Int. J. Mech. Sci., 2001, 43, p 1027–1060

H.S. Kim and S.T.S. Al-Hassani, The Effect of Doubly Tapered Strut Morphology on the Plastic Yield Surface of Cellular Materials, Int. J. Mech. Sci., 2002, 44, p 1559

M. Avalle, G. Belingardi, and A. Ibba, Mechanical Models of Cellular Solids: Parameters Identification from Experimental Tests, Int. J. Impact. Eng., 2007, 34, p 3–27

D. Miedzinska, T. Niezgoda, and R. Gieleta, Numerical and Experimental Aluminium Foam Microstructure Testing With the Use of Computed Tomography, Comp. Mater. Sci., 2012, 64, p 90–95

“International Standard” Iso13314, Mechanical Testing Of Metals-Ductility Testing-Compression Test for Porous and Cellular Metals, 1st ed, 2011

H. Kanahashi, T. Mukai, T.G. Nieh, T. Aizawa, and K. Higashi, Effect of Cell Size on the Dynamic Compressive Properties of Open-Celled Aluminum Foams, Mater. Trans., 2002, 10, p 2548–2553

Conflict of Interests

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamidi Ghaleh Jigh, B., Farsi, M.A. & Hosseini Toudeshky, H. Prediction of the Stress–Strain Behavior of Open-Cell Aluminum Foam under Compressive Loading and the Effects of Various RVE Boundary Conditions. J. of Materi Eng and Perform 27, 2576–2585 (2018). https://doi.org/10.1007/s11665-018-3329-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3329-3