Abstract

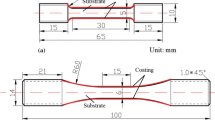

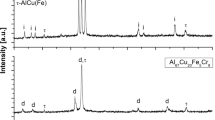

The aim of the present study is to develop thermally sprayable WC-12Co and WC-12Co-xAl2O3 (x = 10 and 15 wt.%) cermet coatings on steel substrate (SS 304) by high-velocity oxy fuel (HVOF) method. Influence of Al2O3 addition on the wear and corrosion behavior of WC-12Co coating has been studied. The microstructure and chemical composition of the coatings were analyzed using field emission scanning electron microscope (FESEM), and phase identification was carried out using x-ray diffraction (XRD) studies. The morphology of the coating appears as coarse granular structure. The XRD studies revealed the presence of hexagonal WC phase along with η-Co6W6C phase. It has been observed from the microhardness measurements, that the values gradually increase from 950 to 1300 HK with the addition of Al2O3 from 0 to 15 wt.%. The wear rate of WC-12Co-15Al2O3 (3.19 × 10−6 mm3/Nm) and WC-12Co-10Al2O3 (5.26 × 10−6 mm3/Nm) coatings was seen to be one order of magnitude lower than that of WC-12Co (2.9 × 10−5 mm3/Nm) coating. The polarization studies revealed that WC-12Co-15Al2O3 cermet coating showed superior corrosion protection than that of WC-12Co-10Al2O3 and WC-12Co coatings. This has been attributed to the gradual decrease in the porosity levels with an increase in Al2O3 content which is supported by morphology studies. The microhardness and wear behavior of WC-12Co-Al2O3 coatings are equivalent to those of hard chrome suggesting the possibility of its replacement.

Similar content being viewed by others

References

F. Rastegar and D.E. Richardson, Alternative to Chrome: HVOF Cermet Coatings for High Horse Power Diesel Engines, Surf. Coat. Technol., 1990, 90, p 156–163

Replacement of chromium plating, HTTP www.sulzermetco.com. 27 Mar 1999

D. Harvey, The Tough Truth–Wear-Resistant Coatings Using High-Velocity Oxyfuel, Ind Lubr Tribol, 1996, 48, p 11–16

M.S. Mahdipoo, F. Tarasi, C. Moreau, A. Dolatabadi, and M. Medraja, HVOF Sprayed Coatings of Nano-Agglomerated Tungsten-Carbide/Cobalt Powders for Water Droplet Erosion Application, Wear, 2015, 330–331, p 338–347

H.B. Wang, X.Z. Wang, X.Y. Song, X.M. Liu, and X.W. Liu, Sliding Wear Behavior of Nanostructured WC-Co-Cr Coatings, Appl. Surf. Sci., 2015, 355, p 453–460

A.C. Karaoglanli, K.M. Doleker, B. Demirel, A. Turk, and R. Varol, Effect of Shot Peening on the Oxidation Behavior of Thermal Barrier Coatings, Appl. Surf. Sci., 2015, 354, p 314–322

A.S. Praveen, J. Sarangan, S. Suresh, and B.H. Channabasappa, Optimization and Erosion Wear the Response of NiCrSiB/WC-Co HVOF Coating Using Taguchi Method, Ceram. Int., 2016, 46, p 1094–1104

P.F. Ruggiero, Tungsten Carbide Coatings Replace Chromium, Adv. Mater. Process., 2005, 163, p 39–40

J.M. Guilemany, J. Fernández, J. Delgado, A.V. Benedetti, and F. Clement, Effects of Thickness Coatings on the Electrochemical Behavior of Thermal Spray Cr3C2-NiCr Coatings, Surf. Coat. Technol., 2002, 153, p 107–113

L. Zhao, M. Maurer, F. Fischer, R. Dicks, and E. Lugscheider, Influence of Spray Parameters on the In-Flight Particle Properties and the Properties of HVOF Coating of WC-CoCr, Wear, 2004, 257, p 41–46

J.M. Guilemany, J.M. Depaco, J. Nutting, and J.R. Miguel, Characterization of the W2C Phase Formed During the HVOF Spraying of a WC-12Co Powder, Metall. Mater. Trans. A, 1999, 30, p 1913–1921

C. Verdon, A. Karimi, and J.L. Martin, A Study of High-Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mater. Sci. Eng. A, 1998, 246, p 11–24

S.Y. Park, M.C. Kim, and C.G. Park, Mechanical Properties and Microstructure Evolution of the Nano WC-Co Coatings Fabricated by Detonation Gun Spraying with Post Heat Treatment, Mater. Sci. Eng. A, 2007, 449–451, p 894–897

R. Bao, J.H. Yi, Y.D. Peng, H.Z. Zhang, and A.K. Li, Decarburization and Improvement of Ultra Fine Straight WC-8Co Sintered Via Microwave Sintering, Trans. Nonferrous Met. Soc. China, 2012, 22, p 853–857

Q. Zhan, L.G. Yu, F.X. Ye, Q.J. Xue, and H. Li, Quantitative Evaluation of the Decarburization and Microstructure Evolution of WC-Co During Plasma Spraying, Surf. Coat. Technol., 2012, 206, p 4068–4074

M. Jafari, M.H. Enayati, M. Salehi, S.M. Naqvi, and C.G. Park, Improvement in Tribological Properties of HVOF Sprayed WC-Co Coatings Using Electroless Ni-P Coated Feedstock Powders, Surf. Coat. Technol., 2013, 235, p 310–317

Q. Yang, T. Senda, and A. Ohmori, Effect of Carbide Grain Size on Microstructure and Sliding Wear Behavior of HVOF-Sprayed WC-12%Co Coatings, Wear, 2003, 254, p 23–34

Y.Y. Wang, C.J. Li, and A. Ohmori, Examination of Factors Influencing the Bond Strength of High Velocity Oxy-Fuel Sprayed Coatings, Surf. Coat. Technol., 2006, 200, p 2923–2928

P. Chivavibul, M. Watanabe, S. Kuroda, and K. Shinoda, Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-Co Coatings, Surf. Coat. Technol., 2007, 202, p 509–521

L.H. Chiu, Y.M. Lin, S.H. Yeh, and H. Chang, Effect of Cryogenic Treatment and Carbide Spray Coating on the Wear Behavior of Carburized Steel, Adv. Mater. Res., 2011, 154–155, p 1143–1151

D.T. Gawne and N.J. Despres, The Influence of Process Conditions on the Friction and Wear of Electrodeposited Chromium Coatings, J. Vac. Sci. Technol., 1985, A3, p 2334

J. Yuan, C. Ma, S. Yang, Z. Yu, and H. Li, Improving the Wear Resistance of HVOF Sprayed WC-Co Coatings by Adding Submicron-Sized WC Particles at the Splats’ Interfaces, Surf. Coat. Technol., 2016, 285, p 17–23

Tom Peat, Alexander M. Galloway, Athanasios I. Toumpis, and David Harvey, Evaluation of the Synergistic Erosion-Corrosion Behaviour of HVOF Thermal Spray Coatings, Surf. Coat. Technol., 2016, 299, p 37–48

L.P. Ward, B. Hinton, D. Gerrard, and K. Short, Corrosion Behaviour of Modified HVOF Sprayed WC Based Cermet Coatings on Stainless Steel, J. Miner. Mater. Charact. Eng., 2011, 10, p 989–1005

M. Takeda, T. Okabe, M. Kido, and Y. Harada, Corrosion Behavior of Thermally Sprayed WC Coating in Na2SO4 aqueous solution, Mater. Trans., 2002, 43, p 2860–2865

Acknowledgments

The authors would like to thank Director, NAL, and Head, SED, for the permission to carry out this work. This work is supported by CSIR, New Delhi, under the network project ESC-01-01. Finally, authors would like to thank Mr. Siju, Mr. Praveen and Mr. Muniprakash for their technical support in FESEM, 3D roughness and wear measurements, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chakradhar, R.P.S., Prasad, G., Venkateswarlu, K. et al. An Investigation on the Wear and Corrosion Behavior of HVOF-Sprayed WC-12Co-Al2O3 Cermet Coating. J. of Materi Eng and Perform 27, 1241–1248 (2018). https://doi.org/10.1007/s11665-018-3240-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3240-y