Abstract

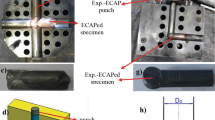

Equal channel angular pressing (ECAP) is an important severe plastic deformation process to produce ultrafine grained microstructures in metals and alloys. Magnesium and its alloys generally possess poor workability at temperatures below 250 °C. This investigation examines the influence of different passes and processing routes of ECAP on improving the workability of Mg alloy AZ31B. ECAP was carried out for three passes using a die of angle 120° using processing routes Bc and C. The operating temperature was 523 K for the first pass and 423 K for the subsequent two passes. The resultant microstructure and mechanical properties were determined. Workability of the alloy at 423 K (150 °C) was determined using upsetting experiments on cylindrical specimens machined from the annealed and ECAPed samples. Workability limit diagrams have been constructed for the various processed conditions. The workability data generated were also analyzed using five different workability criteria (also referred to as ductile fracture models) and the material constants for these five models were evaluated. Specimens processed by two passes through route C (pass 2C) exhibits better workability compared to other passes since the workability limit line after this pass shows maximum safe working area and lies above the other workability lines. Among the five different workability criteria investigated, the Freudenthal workability criterion is more suitable for prediction of failure in this alloy.

Similar content being viewed by others

References

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater Sci., 2006, 51(7), p 881–981

A. Sivaraman and U. Chakkingal, Investigations on Workability of Commercial Purity Aluminum Processed by Equal Channel Angular Pressing, J. Mater. Process. Technol., 2008, 202(1–3), p 543–548

R.Z. Valiev, A.V. Korznikov, and R.R. Mulyukov, Structure and Properties of Ultrafine-Grained Materials Produced by Severe Plastic Deformation, Mater. Sci. Eng. A, 1993, 168(2), p 141–148

V.M. Segal, Equal Channel Angular Extrusion: From Macromechanics to Structure Formation, Mater. Sci. Eng. A, 1999, 271(1), p 322–333

K. Nakashima, Z. Horita, M. Nemoto, and T.G. Langdon, Development of a Multi-Pass Facility for Equal-Channel Angular Pressing to High Total Strains, Mater. Sci. Eng. A, 2000, 281(1), p 82–87

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Principle of Equal-Channel Angular Pressing for the Processing of Ultra-Fine Grained Materials, Scr. Mater., 1996, 35(2), p 143–146

K. Furuno, H. Akamatsu, K. Oh-ishi, and M. Furukawa, Microstructural Development in Equal-Channel Angular Pressing Using a 60 Die, Acta Mater., 2004, 52(9), p 2497–2507

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, The Shearing Characteristics Associated with Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 1998, 257(2), p 328–332

T. Hosaka, S. Yoshihara, I. Amanina, and B.J. Macdonald, Influence of Grain Refinement and Residual Stress on Corrosion Behavior of AZ31 Magnesium Alloy Processed by ECAP in RPMI- 1640 Medium, Procedia Eng., 2017, 184, p 432–441

K. Xia, J.T. Wang, X. Wu, G. Chen, and M. Gurvan, Equal Channel Angular Pressing of Magnesium Alloy AZ31, Mater. Sci. Eng. A, 2005, 410, p 324–327

M. Janeček, M. Popov, M.G. Krieger, R.J. Hellmig, and Y. Estrin, Mechanical Properties and Microstructure of a Mg Alloy AZ31 Prepared by Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 2007, 462(1), p 116–120

P. Kumar and U. Chakkingal, Workability Limits of Commercial Purity Titanium Subjected to Equal Channel Angular Pressing, Mater. Sci. Forum, 2008, 586, p 275–280

A.M. Freudenthal, The Inelastic Behaviour of Solids, Wiley, London, 1950

M.G. Cockcroft and D.J. Latham, Ductility and the Workability of Metals, J. Inst. Met., 1968, 96, p 33–39

P. Brozzo, B. Deluca, R. Rendina, A New Method for the Prediction of Formability Limits in Metal Sheets, in Proceedings of 7th Biennial Conference IDDR (1972)

S.I. Oh, C.C. Chen, and S. Kobayashi, Ductile Fracture in Axisymmetric Extrusion and Drawing, J. Eng. Ind. Trans. ASME, 1979, 101(1), p 36–44

M. Oyane, Criteria of Ductile Fracture Strain, Bull. JSME, 1972, 15(90), p 1507–1513

M. Oyane, T. Sato, K. Okimoto, and S. Shima, Criteria for Ductile Fracture and their Applications, J. Mech. Work. Technol., 1980, 4, p 65–81

S.V.S.N. Murty, B.N. Rao, and B.P. Kashyap, Improved Ductile Fracture Criterion for Cold Forming of Spheroidised Steel, J. Mater. Process. Technol., 2004, 147(1), p 94–101

R.B. Figueiredo and T.G. Langdon, Principles of Grain Refinement and Superplastic Flow in Magnesium Alloys Processed by ECAP, Mater. Sci. Eng. A, 2009, 501, p 105–114

S. Suwas, G. Gottstein, and R. Kumar, Evolution of Crystallographic Texture During Equal Channel Angular Extrusion (ECAE) and Its Effects on Secondary Processing of Magnesium, Mater. Sci. Eng. A, 2007, 471(1–2), p 1–14

S. Biswas, S.S. Dhinwal, and S. Suwas, Room-Temperature Equal Channel Angular Extrusion of Pure Magnesium, Acta Mater., 2010, 58(9), p 3247–3261

R.Z. Valiev, I.V. Alexandrov, Y.T. Zhu, and T.C. Lowe, Paradox of Strength and Ductility in Metals Processed by Severe Plastic Deformation, J. Mater. Res., 2002, 17(1), p 5–8

M.R. Barnett, Z. Keshavarz, A.G. Beer, and D. Atwell, Influence of Grain Size on the Compressive Deformation of Wrought Mg-3Al-1Zn, Acta Mater., 2004, 52(17), p 5093–5103

D. Mohr, M.-A. Chevin, and L. Greve, Deformation Behavior of Magnesium Extrusions with Strong Basal Texture: Experiments and Modeling, J. Appl. Mech., 2013, 80(6), p 61002

Acknowledgments

The authors are thankful to Prof. Satyam Suwas, Indian Institute of Science, Bangalore, for assistance in the texture measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arun, M.S., Chakkingal, U. Workability Limits of Magnesium Alloy AZ31B Subjected to Equal Channel Angular Pressing. J. of Materi Eng and Perform 27, 1352–1360 (2018). https://doi.org/10.1007/s11665-018-3229-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3229-6