Abstract

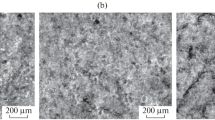

Aluminum sheets-based mirrors are finding applicability in high-temperature solar concentrating technologies because they are cost-effective, lightweight and have high mechanical properties. Nonetheless, the reflectance percentages obtained by electropolishing are not close to the reflectance values of the currently used evaporated films. Therefore, controlling key factors affecting electropolishing processes became essential in order to achieve highly reflective aluminum surfaces. This study investigated the effect of both the electropolishing process and previous heat treatment on the total reflectance of the AA 1100 aluminum alloy. An acid electrolyte and a modified Brytal process were evaluated. Total reflectance was measured by means of UV–Vis spectrophotometry. Reflectance values higher than 80% at 600 nm were achieved for both electrolytes. Optical microscopy and scanning electron microscopy images showed uneven dissolution for the acid electropolished samples causing a reflectance drop in the 200-450 nm region. The influence of heat treatment, previously to electropolishing, was tested at two different temperatures and various holding times. It was found that reflectance increases around 15% for the heat-treated and electropolished samples versus the non-heat-treated ones. A heat treatment at low temperature combined with a short holding time was enough to improve the sample total reflectance.

Similar content being viewed by others

References

A. Herez, M. Ramadan, and M. Khaled, Review on Solar Cooker Systems: Economic and Environmental Study for Different Lebanese Scenarios, Renew. Sustain. Energy Rev., 2017, 2018(81), p 421–432. https://doi.org/10.1016/j.rser.2017.08.021

M. Brogren, A. Helgesson, B. Karlsson, J. Nilsson, and A. Roos, Optical Properties, Durability, and System Aspects of a New Aluminium-Polymer-Laminated Steel Reflector for Solar Concentrators, Sol. Energy Mater. Sol. Cells, 2004, 82(3), p 387–412

R.B. Pettit and E.P. Roth, Solar Mirror Materials: Their Properties and Uses in Solar Concentrating Collectors, Solar Mirror Materials, Academic Press, Inc., Albiquerque, 1980, p 171–197. https://doi.org/10.1016/b978-0-12-511160-7.50012-0

A. Fernández-García, F. Sutter, L. Martínez-Arcos, L. Valenzuela, and C. Sansom, Advanced Mirror Concepts for Concentrating Solar Thermal Systems, Advances in Concentrating Solar Thermal Research and Technology, M. Blanco and L. Ramirez Santigosa, Ed., Elsevier, 2017, p 29–43. https://doi.org/10.1016/b978-0-08-100516-3.00002-2.

R. Almanza, C. Jiefeng, G. Correa, and M. Mazari, Further Option for Solar Concentrators: Aluminum First Surface Mirrors, Sol. Energy, 1995, 54(5), p 333–343

J. Deubener, G. Helsch, A. Moiseev, and H. Bornhöft, Glasses for Solar Energy Conversion Systems, J. Eur. Ceram. Soc., 2009, 29(7), p 1203–1210

A. García-Segura, A. Fernández-García, M.J. Ariza, F. Sutter, and L. Valenzuela, Durability Studies of Solar Reflectors: A Review, Renew. Sustain. Energy Rev., 2016, 62, p 453–467

D. Mills, Advances in Solar Thermal Electricity Technology, Sol. Energy, 2004, 76(1–3), p 19–31

R.E. Hummel, Reflectivity of Silver- and Aluminium-Based Alloys for Solar Reflectors, Sol. Energy, 1981, 27(6), p 449–455

G. Jorgensen, T. Williams, and T. Wendelin, Advanced Reflector Materials for Solar Concentrators, 7th International Symposium on Solar Thermal Concentrating Technologies, (Golden, Colorado 80401-3393 A), National Renewable Energy Laboratory, 1994, p 1–11

T. Fend, B. Hoffschmidt, G. Jorgensen, H. Küster, D. Krüger, R. Pitz-Paal, P. Rietbrock, and K.J. Riffelmann, Comparative Assessment of Solar Concentrator Materials, Sol. Energy, 2003, 74(2), p 149–155

C.E. Kennedy, R.V. Smilgys, D.A. Kirkpatrick, and J.S. Ross, Optical Performance and Durability of Solar Reflectors Protected by an Alumina Coating, Thin Solid Films, 1997, 304(1–2), p 303–309. https://doi.org/10.1016/s0040-6090(97)00198-3

T. Fend, G. Jorgensen, and H. Küster, Applicability of Highly Reflective Aluminium Coil for Solar Concentrators, Sol. Energy, 2000, 68(4), p 361–370

J.E. Hatch and Aluminum Association, Aluminum: Properties and Physical Metallurgy, ASM International, OH, 1984

M. Bauccio, ASM Metal Reference Book, 3rd ed., ASM International, Materials Park, 1993

P.G. Wernick, S. Pinner, and R. Sheasby, The Surface Treatment and Finishing of Aluminum and Its Alloys, 5th ed., ASM International, Great Britain, 1987, p 1–1273

O. Jessensky, F. Müller, and U. Gösele, Self-Organized Formation of Hexagonal Pore Arrays in Anodic Alumina, Appl. Phys. Lett., 1998, 72(10), p 1173–1175

S. Van Gils, S. Holten, E. Stijns, M. Vancaldenhoven, H. Terryn, and L. Mattsson, Electropolishing of Aluminium: Processing and Assessment of Visual Appearance, Surf. Interface Anal., 2003, 35(2), p 121–127

M.G. Holló, A New Interpretation of the Substructure of Electropolished Aluminium Surfaces, Acta Metall., 1960, 8, p 265–268

H. Asoh, S. Ono, T. Hirose, M. Nakao, and H. Masuda, Growth of Anodic Porous Alumina with Square Cells, Electrochim. Acta, 2003, 48(20–22), p 3171–3174

S. Ono, M. Saito, and H. Asoh, Self-Ordering of Anodic Porous Alumina Induced by Local Current Concentration: Burning, Electrochem. Solid-State Lett., 2004, 7(7), p B21–B24. https://doi.org/10.1149/1.1738553

S. Ono, M. Saito, and H. Asoh, Self-Ordering of Anodic Porous Alumina Formed in Organic Acid Electrolytes, Electrochim. Acta, 2005, 51(5), p 827–833

H. Asoh, K. Nishio, M. Nakao, T. Tamamura, and H. Masuda, Conditions for Fabrication of Ideally Ordered Anodic Porous Alumina Using Pretextured Al, J. Electrochem. Soc., 2001, 148(4), p B152–B156

F. Rashidi, T. Masuda, H. Asoh, and S. Ono, Metallographic Effects of Pure Aluminum on Properties of Nanoporous Anodic Alumina (NPAA), Surf. Interface Anal., 2013, 45(10), p 1490–1496

C. Chi, J.-H. Lee, I. Kim, and H.-J. Oh, Effects of Annealing Treatment of Aluminum Substrate on Nanopore Arrangements in Anodic Alumina, J. Mater. Sci. Technol., 2015, 31(7), p 751–758. https://doi.org/10.1016/j.jmst.2014.09.019

C.K. Chung, M.W. Liao, H.C. Chang, and C.T. Lee, Effects of Temperature and Voltage Mode on Nanoporous Anodic Aluminum Oxide Films by One-Step Anodization, Thin Solid Films, 2011, 520(5), p 1554–1558. https://doi.org/10.1016/j.tsf.2011.08.053

J. De Laet, H. Terryn, and J. Vereecken, Development of an Optical Model for Steady State Porous Anodic Films on Aluminium Formed in Phosphoric Acid, Thin Solid Films, Elsevier, 1998, 320(2), p 241–252. https://doi.org/10.1016/s0040-6090(97)00741-4

J. Ferré-Borrull, J. Pallarès, G. Macías, and L.F. Marsal, Nanostructural Engineering of Nanoporous Anodic Alumina for Biosensing Applications, Materials, 2014, 7(7), p 5225–5253

L.P. Hernández-Eguía, J. Ferré-Borrull, G. Macias, J. Pallarès, and L.F. Marsal, Engineering Optical Properties of Gold-Coated Nanoporous Anodic Alumina for Biosensing, Nanoscale Res. Lett., 2014, 9(1), p 414. https://doi.org/10.1186/1556-276x-9-414

S. Ono and N. Masuko, The Duplex Structure of Cell Walls of Porous Anodic Films Formed on Aluminum, Corrosion Science, 1992, 33(3), p 503–507. http://www.sciencedirect.com/science/article/pii/0010938X9290078H

X. Hu, Y.J. Pu, Z.Y. Ling, and Y. Li, Coloring of Aluminum Using Photonic Crystals of Porous Alumina with Electrodeposited Ag, Opt. Mater., 2009, 32(2), p 382–386

G.S. Huang, X.L. Wu, Y.F. Mei, X.F. Shao, and G.G. Siu, Strong Blue Emission from Anodic Alumina Membranes with Ordered Nanopore Array, J. Appl. Phys., 2003, 93(1), p 582–585

G.S. Huang, X.L. Wu, L.W. Yang, X.F. Shao, G.G. Siu, and P.K. Chu, Dependence of Blue-Emitting Property on Nanopore Geometrical Structure in Al-Based Porous Anodic Alumina Membranes, Appl. Phys. A Mater. Sci. Process., 2005, 81(7), p 1345–1349

T. Kumeria, M.M. Rahman, A. Santos, J. Ferré-Borrull, L.F. Marsal, and D. Losic, Structural and Optical Nanoengineering of Nanoporous Anodic Alumina Rugate Filters for Real-Time and Label-Free Biosensing Applications, Anal. Chem., 2014, 86(3), p 1837–1844

T. Kumeria, A. Santos, and D. Losic, Nanoporous Anodic Alumina Platforms: Engineered Surface Chemistry and Structure for Optical Sensing Applications, Sensors, 2014, 14(7), p 11878–11918. https://doi.org/10.3390/s140711878

A.A. Schilt, Perchloric Acid and Perchlorates, The G. Frederick Smith Chemical Company, DeKalb, 1979

H. Adelkhani, S. Nasoodi, and A.H. Jafari, A Study of the Morphology and Optical Properties of Electropolished Aluminum in the Vis-IR Region, Int. J. Electrochem. Sci., 2009, 4(2), p 238–246

L. George and S. Eric, Destruction of Hazardous Chemicals in the Laboratory, 3rd ed., Wiley, New York, 2012

K.M. Alam, A.P. Singh, S.C. Bodepudi, and S. Pramanik, Fabrication of Hexagonally Ordered Nanopores in Anodic Alumina: An Alternative Pretreatment, Surf. Sci., 2011, 605(3–4), p 441–449

D. Joseph, Aluminum and Aluminum Alloys, 1st ed., ASM International, Materials Park, 2001

W.G. Wood, Metals Handbook, Surface Cleaning Finishing and Coating, Vol 5, American Society of Metals, Materials Park, 1982

D. Mardare and G.I. Rusu, The Influence of Heat Treatment on the Optical Properties of Titanium Oxide Thin Films, Mater. Lett., 2002, 56(3), p 210–214

B. Hugh, ASM Handbook Volume 3—Alloy Phase Diagrams, ASM Handbook, 1992, p 500

R. Ambat, A.J. Davenport, G.M. Scamans, and A. Afseth, Effect of Iron-Containing Intermetallic Particles on the Corrosion Behaviour of Aluminium, Corros. Sci., 2006, 48(11), p 3455–3471

J. Namahoot, Effect of Deformation on Corrosion of Al-Mn Alloys, Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2004

ASM International Handbook Committee, Metals Handbook Vol 13 - Corrosion, ASM Handbook, 9th, ASM International, 1992

ASM International, Heat Treating, Vol 4, ASM International, Materials Park, OH, 1991

J.G. Kaufman and E.L. Rooy, Aluminum Alloy Castings Properties, Processes, and Applications, ASM International, Materials Park, OH, 2004

F. Eozenou, C. Antoine, A. Aspart, S. Berry, J.F. Denis, and B. Malki, Efficiency of Electropolishing Versus Bath Composition and Aging: First Results, 2005, p 2–5

M. Buhlert, M. Gartner, M. Modreanu, A. Jitianu, R. Gavrila, A. Awad, and P.J. Plath, Characterization of Electropolished Aluminum Surfaces, Galvanotechnik, 2004, 95, p 1629–1634

R. Pinner, Electroplating and Metal Finishing, Electroplating and Metal Finishing, 1953, 6(11), p 401–410

C.F. Mallinson, P.M. Yates, M.A. Baker, J.E. Castle, A. Harvey, and J.F. Watts, The Localised Corrosion Associated with Individual Second Phase Particles in AA7075-T6: A Study by SEM, EDX, AES, SKPFM and FIB-SEM, Mater. Corros., 2017, (October 2016), p 1–16

S.M. Li, Y.D. Li, Y. Zhang, J.H. Liu, and M. Yu, Effect of Intermetallic Phases on the Anodic Oxidation and Corrosion of 5A06 Aluminum Alloy, International Journal of Minerals, Metallurgy and Materials, 2015, 22(2), p 167–174

O. Lunder and K. Nisancioglu, Effect of Alkaline-Etch Pretreatment on the Pitting Corrosion of Wrought Aluminum, Corrosion, 1988, 44(7), p 414–422

B. Wielage, D. Nickel, G. Alisch, H. Podlesak, and T. Lampke, Effects of Pre-Treatment on the Growth Rate and Morphology of Hard Anodic Films on Aluminium (EN AW-6082), Surf. Coat. Technol., 2007, 202(3), p 569–576

Z. Szklarska-Smialowska, Pitting Corrosion of Aluminum, Corros. Sci., 1998, 1999(41), p 1743–1767

I. Son, H. Nakano, S. Oue, S. Kobayashi, H. Fukushima, and Z. Horita, Effect of Equal-Channel Angular Pressing on Pitting Corrosion of Pure Aluminum, International Journal of Corrosion, 2012, 2012, p 1–9

S.J. Garcia-Vergara, P. Skeldon, G.E. Thompson, P. Bailey, T.C.Q. Noakes, H. Habazaki, and K. Shimizu, Morphology of Enriched Alloy Layers in an Anodized Al-Cu Alloy, Appl. Surf. Sci., 2002, 205(1–4), p 121–127

Y. Osawa, S. Takamori, T. Kimura, K. Minagawa, and H. Kakisawa, Morphology of Intermetallic Compounds in Al-Si-Fe Alloy and Its Control by Ultrasonic Vibration, Mater. Trans., 2007, 48(9), p 2467–2475. https://doi.org/10.2320/matertrans.f-mra2007874

J.A. Taylor, Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys, Procedia Materials Science, 2012, 1, p 19–33. https://doi.org/10.1016/j.mspro.2012.06.004

G. Ghosh, Aluminium – Iron – Silicon, Iron Systems, Part 1, G. Effenberg and S. Ilyenko, Eds., Landolt-Börnstein, 2006.

Davis Joseph, “Corrosion of Aluminum and Aluminum Alloys,” Davids and Asociates, Ed., (Ohio), ASM International, 1999.

I. Boukerche, S. Djerad, L. Benmansour, L. Tifouti, and K. Saleh, Degradability of Aluminum in Acidic and Alkaline Solutions, Corros. Sci., 2014, 78(January), p 343–352

G.E. Totten and D.S. Mackenzie, Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes, 1st ed., CRC Press, Boca Raton, 2003

Acknowledgments

This work was supported by COLCIENCIAS and Universidad de Antioquia, Colombia, with Contract Number: 0636-2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aguilar-Sierra, S.M., Echeverría E, F. Improvement of Electropolishing of 1100 Al Alloy for Solar Thermal Applications. J. of Materi Eng and Perform 27, 1387–1395 (2018). https://doi.org/10.1007/s11665-018-3212-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3212-2