Abstract

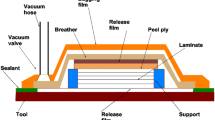

This study investigates the synergistic effects of graphene oxide (GO) on the woven carbon fiber (CF)-reinforced epoxy composites. The GO nanofiller was incorporated into the epoxy resin with variations in the content, and the CF/epoxy composites were manufactured using a vacuum-assisted resin transfer molding process and then cured at 70 and 120 °C. An analysis of the mechanical properties of the GO (0.2 wt.%)/CF/epoxy composites showed an improvement in the tensile strength, Young’s modulus, toughness, flexural strength and flexural modulus by ~ 34, 20, 83, 55 and 31%, respectively, when compared to the CF/epoxy composite. The dynamic mechanical analysis of the composites exhibited an enhancement of ~ 56, 114 and 22% in the storage modulus, loss modulus and damping capacity (tanδ), respectively, at its glass transition temperature. The fiber–matrix interaction was studied using a Cole–Cole plot analysis.

Similar content being viewed by others

References

A. Godara, L. Gorbatikh, G. Kalinka, A. Warrier, O. Rochez, and L. Mezzo, Interfacial Shear Strength of a Glass Fiber/Epoxy Bonding in Composites Modified with Carbon Nanotubes, Compos. Sci. Technol., 2010, 70(9), p 1346–1352

N. Yamamoto, J.A. Hart, E.J. Garcia, S.S. Wicks, H.M. Duong, and A.H. Slocum, High-Yield Growth and Morphology Control of Aligned Carbon Nanotubes on Ceramic Fibers for Multifunctional Enhancement of Structural Composites, Carbon, 2009, 47(3), p 551–560

F.H. Su, Z.Z. Zhang, and W.M. Liu, Study on the Friction and Wear Properties of Glass Fabric Composites Filled with Nano and Micro Particles Under Different Conditions, Mater. Sci. Eng., A, 2005, 392(1–2), p 359–365

Z.Z. Zhang, F.H. Su, K. Wang, W. Jiang, X.H. Men, and W.M. Liu, Study on the Friction and Wear Properties of Carbon Fabric Composites Reinforced with Micro and Nano Particles, Mater. Sci. Eng., A, 2005, 404(1–2), p 251–258

S.A. Meguid and Y. Sun, On the Tensile and Shear Strength of Nano-Reinforced Composite Interfaces, Mater. Des., 2004, 25(4), p 289–296

F. Kachold and R. Singer, Mechanical Properties of Carbon Fiber-Reinforced Aluminum Manufactured by High-Pressure Die Casting, J. Mater. Eng. Perf., 2016, 25(8), p 3128–3133

F. Cai, F. Gao, S. Pant, X. Huang, and Q. Yang, Solid Particle Erosion Behaviors of Carbon-Fiber Epoxy Composite and Pure Titanium, J. Mater. Eng. Perf., 2016, 25(1), p 290–296

R.M. Rocha, C.A.A. Cairo, and M.L.A. Graca, Formation of Carbon Fiber-Reinforced Ceramic Matrix Composites with Polysiloxane/Silicon Derived Matrix, Mater. Sci. Eng., 2006, 437(2), p 268–273

Y. Arao, S. Yumitori, H. Suzuki, T. Tanaka, K. Tanaka, and T. Katayama, Mechanical Properties of Injection-Molded Carbon Fiber/Polypropylene Composites Hybridized with Nanofillers, Compos. Part A, 2013, 55, p 19–26

Y. Geng, M.Y. Liu, J. Li, X.M. Shi, and J.K. Kim, Effects of Surfactant Treatment on Mechanical and Electrical Properties of CNT/Epoxy Nanocomposites, Compos. Part A, 2008, 39(12), p 1876–1883

Z. Spitalsky, D. Tasis, K. Papagelis, and C. Galiotis, Carbon Nanotube-Polymer Composites: Chemistry, Processing, Mechanical and Electrical Properties, Prog. Polym. Sci., 2010, 35(3), p 357–401

C.E. Hong, J.H. Lee, P. Kalappa, and S.G. Advani, Effects of Oxidative Conditions on Properties of Multi-walled Carbon Nanotubes in Polymer Nanocomposites, Compos. Sci. Technol., 2007, 67(6), p 1027–1034

N. Liu, F. Luo, H. Wu, Y. Liu, C. Zhang, and J. Chen, Onestep Ionic-Liquid-Assisted Electrochemical Synthesis of Ionicliquid-Functionalized Graphene Sheets Directly from Graphite, Adv. Funct. Mater., 2008, 18, p 1518–1525

L. Wang, J. Hong, and G. Chen, Comparison Study of Graphite Nanosheets and Carbon Black as Fillers for High Density Polyethylene, Polym. Eng. Sci., 2010, 50(11), p 2176–2181

R. Baptista, A. Mendão, M. Guedes, and R. Marat-Mendesa, An Experimental Study on Mechanical Properties of Epoxy-Matrix Composites Containing Graphite Filler, Proc. Struct. Integr., 2016, 1, p 074–081

K. Kalaitzidou, H. Fukushima, and L.T. Drzal, A New Compounding Method for Exfoliated Graphite-Polypropylene Nanocomposites with Enhanced Flexural Properties and Lower Percolation Threshold, Compos. Sci. Technol., 2007, 67(10), p 2045–2051

S. Park and S.R. Ruoff, Chemical Methods for the Production of Graphenes, Nat. Nanotechnol., 2009, 4, p 217–224

S. Stankovich, D.A. Dikin, G.H.B. Dommett, K.M. Kohlhaas, E.J. Zimney, E.A. Stach, R.D. Piner, S.T. Nguyen, and R.S. Ruoff, Graphene-Based Composite Materials, Nature, 2006, 442, p 282–286

C.Y. Lee, J.H. Bae, T.Y. Kim, S.H. Chang, and S.Y. Kim, Using Silane-Functionalized Graphene Oxides for Enhancing the Interfacial Bonding Strength of Carbon/Epoxy Composites, Compos. Part A, 2015, 75, p 11–17

A.K. Pathak, M. Borah, A. Gupta, T. Yokozeki, and S.R. Dhakate, Improved Mechanical Properties of Carbon Fiber/Graphene Oxide/Epoxy Hybrid Composites, Compos. Sci. Technol., 2016, 135, p 28–38

P. He, B. Huang, L. Liu, Q. Huang, and T. Chen, Preparation of Multiscale Graphene Oxide-Carbon Fabric and Its Effect on Mechanical Properties of Hierarchical Epoxy Resin Composite, Polym. Compos., 2016, 37(5), p 1515–1522

X. Zhang, X. Fan, C. Yan, H. Li, Y. Zhu, X. Li, and L. Yu, Interfacial Microstructure and Properties of Carbon Fiber Composites Modified with Graphene Oxide, ACS Appl. Mater. Interfaces., 2012, 4(3), p 1543–1552

T. Kuila, S. Bose, P. Khanra, A.K. Mishra, N.H. Kim, and J.H. Lee, A Green Approach for the Reduction of Graphene Oxide by Wild Carrot Root, Carbon, 2012, 50(3), p 914–921

H.K. Jeong, Y.P. Lee, R.J. Lahaye, M.H. Park, K.H. An, I.J. Kim, C.W. Yang, C.Y. Park, R.S. Ruoff, and Y.H. Lee, Evidence of Graphitic AB Stacking Order of Graphite Oxides, J. Am. Chem. Soc., 2008, 130(4), p 1362–1366

D.C. Davis, J.W. Wilkerson, J. Zhu, and D.O.O. Ayewah, Improvements in Mechanical Properties of a Carbon Fiber Epoxy Composite Using Nanotube Science and Technology, Compos. Struct., 2010, 92(11), p 2653–2662

J.M.F. Paiva, E. Frollini, and J. Macromol, Unmodified and Modified Surface Sisal Fibers as Reinforcement of Phenolic and Lignophenolic Matrices Composites: Thermal Analyses of Fibers and Composites, Mater. Eng., 2006, 291(4), p 405–417

S. Ganguli, A.K. Roy, and D.P. Anderson, Improved Thermal Conductivity for Chemically Functionalized Exfoliated Graphite/Epoxy Composites, Carbon, 2008, 46(5), p 806–817

N.G. McCrum, B. Read, and G. Williams, Anelastic & Dielectric Effects in Polymer Solids, Wiley, New York, 1967

N. Hameed, P.A. Sreekumar, B. Francis, W. Yang, and S. Thomas, Morphology, Dynamic Mechanical and Thermal Studies on Poly(styrene-co-acrylonitrile) Modified Epoxy Resin/Glass Fibre Composites, Compos. Part A, 2007, 38(12), p 2422–2432

H. Kaddami, A. Dufresne, B. Khelifi, A. Bendahou, M. Taourirte, M. Raihane, N. Issartel, H. Sautereau, J.F. Gerard, and N. Sami, Short Palm Tree Fibres-Thermoset Matrices Composites, Compos. Part A, 2006, 37(9), p 1413–1422

S. Chhetri, P. Samanta, N.C. Murmu, S.K. Srivastava, and T. Kuila, Effect of Dodecyal Amine Functionalized Graphene on the Mechanical and Thermal Properties of Epoxy-Based Composites, Polym. Eng. Sci., 2016, 56(11), p 1221–1228

M. Jawaid and H.P.S. Khalil, Effect of Layering Pattern on the Dynamic Mechanical Properties and Thermal Degradation of Oil Palm-Jute Fiber Reinforced Epoxy Hybrid Composites, Bio-Resources, 2011, 6(3), p 2309–2322

G. Agarwal, A. Patnaik, and R.K. Sharma, Tribology Material, Parametric Optimization of Three Body Abrasive Wear Behaviour of Long and Short Carbon Fiber Reinforced Epoxy Composites, Tribol. Mater. Surf. Interfaces, 2013, 7(3), p 150–160

Acknowledgments

The authors are thankful to the Director of CSIR-CMERI. The authors are also thankful to the Council of Scientific and Industrial Research, New Delhi, India, for funding MEGA Institutional Project (ESC0112/RP-II/T2.3).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Adak, N.C., Chhetri, S., Kim, N.H. et al. Static and Dynamic Mechanical Properties of Graphene Oxide-Incorporated Woven Carbon Fiber/Epoxy Composite. J. of Materi Eng and Perform 27, 1138–1147 (2018). https://doi.org/10.1007/s11665-018-3201-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3201-5