Abstract

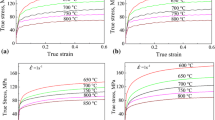

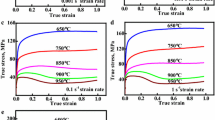

Hot compressive deformation behavior of the Cu-Zr-Ce alloy has been investigated according to the hot deformation tests in the 550-900 °C temperature range and 0.001-10 s−1 strain rate range. Based on the true stress–true strain curves, the flow stress behavior of the Cu-Zr-Ce alloy was investigated. Microstructure evolution was observed by optical microscopy. Based on the experimental results, a constitutive equation, which reflects the relationships between the stress, strain, strain rate and temperature, has been established. Material constants n, α, Q and ln A were calculated as functions of strain. The equation predicting the flow stress combined with these materials constants has been proposed. The predicted stress is consistent with experimental stress, indicating that developed constitutive equation can adequately predict the flow stress of the Cu-Zr-Ce alloy. Dynamic recrystallization critical strain was determined using the work hardening rate method. According to the dynamic material model, the processing maps for the Cu-Zr and Cu-Zr-Ce alloy were obtained at 0.4 and 0.5 strain. Based on the processing maps and microstructure observations, the optimal processing parameters for the two alloys were determined, and it was found that the addition of Ce can promote the hot workability of the Cu-Zr alloy.

Similar content being viewed by others

References

J.R. Davis, Copper and Copper Alloys. ASM Specialty Handbook (ASM International, USA, 2001), p. 153

L.M. Bi, P. Liu, X.H. Chen, X.K. Liu, W. Li, and F.C. Ma, Analysis of Phase in Cu-15%Cr-0.24%Zr Alloy, Trans. Nonferrous Met. Soc. China, 2013, 23(5), p 1342

Y. Zhang, A.A. Volinsky, H.T. Tran, Z. Chai, P. Liu, B.H. Tian, and Y. Liu, Aging Behavior and Precipitates Analysis of the Cu-Cr-Zr-Ce Alloy, Mater. Sci. Eng. A, 2016, 650, p 248

J.H. Su, Q.M. Dong, P. Liu, H.J. Li, and B.X. Kang, Research on Aging Precipitation in a Cu-Cr-Zr-Mg Alloy, Mater. Sci. Eng. A, 2005, 392(1), p 422

L.K.L. Falk, P.R. Howell, G.L. Dunlop, and T.G. Langdon, The Role of Matrix Dislocations in the Superplastic Deformation of a Copper Alloy, Acta Metall., 1986, 34(7), p 1203

S.C. Krishna, G.S. Rao, A.K. Jha, B. Pant, and P.V. Venkitakrishnan, Strengthening in High Strength Cu-Cr-Zr-Ti Alloy Plates Produced by Hot Rolling, Mater. Sci. Eng. A, 2016, 674, p 164

A.Y. Khereddine, F.H. Larbi, H. Azzeddine, T. Baudin, F. Brisset, A.L. Helbert, M.H. Mathon, M. Kawasaki, D. Bradai, and T.G. Langdon, Microstructures and Textures of a Cu-Ni-Si Alloy Processed by High-Pressure Torsion, J. Alloys Compd., 2013, 574, p 361

H. Zhang, H.G. Zhang, and L.X. Li, Hot Deformation Behavior of Cu-Fe-P Alloys During Compression at Elevated Temperatures, J. Mater. Process. Technol., 2009, 209(6), p 2892

L.J. Peng, H.F. Xie, G.J. Huang, Y.F. Li, X.Q. Yin, X. Feng, X.J. Mi, and Z. Yang, The Phase Transformation and Its Effects on Properties of a Cu-0.12 wt.%Zr Alloy, Mater. Sci. Eng. A, 2015, 633, p 28

Y. Ye, X. Yang, J. Wang, X. Zhang, Z. Zhang, and T. Sakai, Enhanced Strength and Electrical Conductivity of Cu-Zr-B Alloy by Double Deformation-Aging Process, J. Alloys Compd., 2014, 615, p 249

J. Wongsa-Ngam, M. Kawasaki, Y. Zhao, and T.G. Langdon, Microstructural Evolution and Mechanical Properties of a Cu-Zr Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2011, 528(25-6), p 7715

V.A. Phillips, Electron Microscope Observations on Precipitation in a Cu-1.07 %Zr Alloy, Metallography, 1974, 7(2), p 137

K. Wang, K.F. Liu, and J.B. Zhang, Microstructure and Properties of Aging Cu-Cr-Zr Alloy, Rare Met., 2014, 33(2), p 134

Z. Yang, F. Zhang, C. Zheng, M. Zhang, B. Lv, and L. Qu, Study on Hot Deformation Behaviour and Processing Maps of Low Carbon Bainitic Steel, Mater. Des., 2015, 66, p 258

B. Li, Q. Pan, and Z. Yin, Microstructural Evolution and Constitutive Relationship of Al-Zn-Mg Alloy Containing Small Amount of Sc and Zr During Hot Deformation Based on Arrhenius-Type and Artificial Neural Network Models, J. Alloys Compd., 2014, 584, p 406

Y. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733

Y. Zhang, B.H. Tian, A.A. Volinsky, H.L. Sun, Z. Chai, P. Liu, X.H. Chen, and Y. Liu, Dynamic Recrystallization Model of the Cu-Cr-Zr-Ag Alloy Under Hot Deformation, J. Mater. Res., 2016, 31, p 1275

C.M. Sellars and W.J. Mctegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136

N. Haghdadi, A. Zarei-Hanzaki, and H.R. Abedi, The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures Considering the Effect of Strain, Mater. Sci. Eng. A, 2012, 535, p 252

Y. Cao, H. Di, R.D.K. Misra, X. Yi, J.C. Zhang, and T.J. Ma, On the Hot Deformation Behavior of AISI, 420 Stainless Steel Based on Constitutive Analysis and CSL Model, Mater. Sci. Eng. A, 2014, 593, p 111

Y. Zhang, H.L. Sun, A.A. Volinsky, B.H. Tian, Z. Chai, P. Liu, and Y. Liu, Hot Deformation and Dynamic Recrystallization Behavior of the Cu-Cr-Zr-Y Alloy, J. Mater. Eng. Perform., 2016, 25(3), p 1150

A. Galiyev, R. Kaibyshev, and G. Gottstein, Correlation of Plastic Deformation and Dynamic Recrystallization in Magnesium Alloy ZK60, Acta Mater., 2001, 49(7), p 1199

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22

Y.H. Xiao, C. Guo, and X.Y. Guo, Constitutive Modeling of Hot Deformation Behavior of H62 Brass, Mater. Sci. Eng. A, 2011, 528(21), p 6510

Z.Y. Ding, S.G. Jia, P.F. Zhao, M. Deng, and K.X. Song, Hot Deformation Behavior of Cu-0.6 Cr-0.03 Zr Alloy During Compression at Elevated Temperatures, Mater. Sci. Eng. A, 2013, 570, p 87

Y. Zhang, A.A. Volinsky, H.T. Tran, Z. Chai, P. Liu, and B.H. Tian, Effects of Ce Addition on High Temperature Deformation Behavior of Cu-Cr-Zr Alloys, J. Mater. Eng. Perform., 2015, 24(10), p 3783

G.L. Ji, Q. Li, K.Y. Ding, L. Yang, and L. Li, A Physically-Based Constitutive Model for High Temperature Deformation of Cu-0.36 Cr-0.03 Zr Alloy, J. Alloys Compd., 2015, 648, p 397

C.L. Gan, Y.D. Xue, and M.J. Wang, Prediction of the Flow Stress of Al6061 at Hot Deformation Conditions, Mater. Sci. Eng. A, 2011, 528, p 4199

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comp. Mater. Sci., 2008, 42(3), p 470

Z.W. Cai, F.X. Chen, and J.Q. Guo, Constitutive Model for Elevated Temperature Flow Stress of AZ41M Magnesium Alloy Considering the Compensation of Strain, J. Alloys Compd., 2015, 648, p 215

E.I. Poliak and J.J. Jonas, Critical Strain for Dynamic Recrystallization in Variable Strain Rate Hot Deformation, ISIJ Int., 2003, 43, p 684

H.L. Sun, Y. Zhang, A.A. Volinsky, B.J. Wang, B.H. Tian, Z. Chai, and Y. Liu, Effects of Ag Addition on Hot Deformation Behavior of Cu-Ni-Si Alloys. Adv. Eng. Mater. 2017, 19(3). https://doi.org/10.1002/adem.201600607

H. Mirzadeh and A. Najafizadeh, Prediction of the Critical Conditions for Initiation of Dynamic Recrystallization, Mater. Des., 2010, 31(3), p 1174

G.J. Huang, B.H. Qian, L.Y. Wang, and J.J. Jonas, Study on the Critical Conditions for Initial Dynamic Recrystallization of AZ31 Magnesium Alloy, Rare Met. Mater. Eng., 2007, 36(12), p 2080

E.S. Puchi-Cabrera, M.H. Staia, J.D. Guerin, J. Lesage, M. Dubar, and D. Chicot, Analysis of the Work-Hardening Behavior of C-Mn Steels Deformed Under Hot-Working Conditions, Int. J. Plast, 2013, 51, p 145

Y.V.R.K. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 82

T.D. Kil, J.M. Lee, and Y.H. Moon, Quantitative Formability Estimation of Ring Rolling Process by Using Deformation Processing Map, J. Mater. Process. Technol., 2015, 220, p 224

T. Xi, C.G. Yang, M.B. Shahzad, and K. Yang, Study of the Processing Map and Hot Deformation Behavior of a Cu-Bearing 317LN Austenitic Stainless Steel, Mater. Des., 2015, 87, p 303

D.J. Li, Y.R. Feng, Z.F. Yin, F.S. Shangguan, K. Wang, Q. Liu, and F. Hu, Prediction of Hot Deformation Behaviour of Fe-25Mn-3Si-3Al TWIP Steel, Mater. Sci. Eng. A, 2011, 528(28), p 8084

Y. Zhang, B.H. Tian, A.A. Volinsky, X.H. Chen, H.L. Sun, Z. Chai, P. Liu, and Y. Liu, Dynamic Recrystallization Model of the Cu-Cr-Zr-Ag Alloy Under Hot Deformation, J. Mater. Res., 2016, 31(9), p 1275

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51101052) and the National Science Foundation (IRES 1358088).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Y., Sun, H., Volinsky, A.A. et al. Constitutive Model for Hot Deformation of the Cu-Zr-Ce Alloy. J. of Materi Eng and Perform 27, 728–738 (2018). https://doi.org/10.1007/s11665-018-3168-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3168-2