Abstract

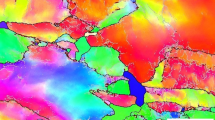

Adiabatic shear localization plays an important role in the deformation and failure of ultrafine grained 6061 aluminum alloy processed by friction stir processing. To understand the effects of temperature and strain on adiabatic shear localization in the ultrafine grained 6061 aluminum alloy, it has been investigated dynamic mechanical behavior of ultrafine grained 6061 aluminum alloy under the controlled shock loading experiments. Deformation characteristics and microstructures in the shear band were performed by optical microscopy and transmission electron microscopy. The shear band in the ultrafine grained aluminum alloy is a long and straight band distinguished from the matrix. The width of the shear band decreases with increasing nominal strain. The results show that the grains in the boundary of the shear band are highly elongated along the shear direction and form the elongated cell structures (0.2 μ in width), and the core of the shear band consists of a number of recrystallized equiaxed grains 0.2-0.3 μ in diameters and the second phases distribute in both the boundary and the inner of the equiaxed new grains. The calculated temperature in the shear band is about 692 K. Rotational dynamic recrystallization mechanism is responsible for the formation of the microstructure in the shear band.

Similar content being viewed by others

References

L.F. Peng, M.Y. Mao, M.W. Fu, and X.M. Lai, Effect of Grain Size on the Adhesive and Ploughing Friction Behaviours of Polycrystalline Metals in Forming Process, Int. J. Mech. Sci., 2016, 117, p 197–209

M.M. Mahdavian, L. Ghalandari, and M. Reihanian, Accumulative Roll Bonding of Multilayered Cu/Zn/Al: An Evaluation of Microstructure and Mechanical Properties, Mater. Sci. Eng., A, 2013, 579, p 99–107

N. Sridharan, M. Gussev, R. Seibert, C. Parish, M. Norfolk, K. Terrani, and S.S. Babu, Rationalization of Anisotropic Mechanical Properties of Al-6061 Fabricated Using Ultrasonic Additive Manufacturing, Acta Mater., 2016, 117, p 228–237

C. Xu, M. Furukawa, Z. Horita, and T.G. Langdon, Using ECAP to Achieve Grain Refinement, Precipitate Fragmentation and High Strain Rate Superplasticity in a Spray-Cast Aluminum Alloy, Acta Mater., 2003, 51, p 6139–6149

Y.H. Zhao, X.Z. Liao, S. Cheng, E. Ma, and Y.T. Zhu, Simultaneously Increasing the Ductility and Strength of Nanostructured Alloys, Adv. Mater., 2006, 18, p 2280–2283

B. Dodd and Y.L. Bai, Adiabatic Shear Localization: Frontiers and Advances, Seconded, Elsevier Science Ltd, London, 2012

B.F. Wang, X.Y. Wang, Z.Z. Li, R. Ma, S.T. Zhao, F.Y. Xie, and X.Y. Zhang, Shear Localization and Microstructure in Coarse Grained Beta Titanium Alloy, Mater. Sci. Eng., A, 2016, 652, p 287–295

B. Dodd and Y.L. Bai, Width of Adiabatic Shear Bands Formed Under Combined Stresses, Mater. Sci. Technol., 1989, 5, p 557–559

D.E. Grady, Dissipation in Adiabatic Shear Bands, Mech. Mater., 1994, 17, p 289–293

J. An, Y.F. Wang, Q.Y. Wang, W.Q. Cao, and C.X. Huang, The Effects of Reducing Specimen Thickness on Mechanical Behavior of Cryo-Rolled Ultrafine-Grained Copper, Mater. Sci. Eng., A, 2016, 651, p 1–7

Y. Xu, J. Zhang, Y. Bai, and M.A. Meyers, Shear Localization in Dynamic Deformation: Microstructural Evolution, Metall. Mater. Trans. A, 2008, 39, p 811–843

G.M. Owolabi, D.T. Bolling, A.A. Tiamiyu, R. Abu, A.G. Odeshi, and H.A. Whitworth, Shear Strain Localization in AA 2219-T8 Aluminum Alloy at High Strain Rates, Mater. Sci. Eng., A, 2016, 655, p 212–220

Y. Jiang, Z. Chen, C. Zhan, T. Chen, R. Wang, and C. Liu, Adiabatic Shear Localization in Pure Titanium Deformed by Dynamic Loading: Microstructure and Microtexture Characteristic, Metall. Mater. Sci. Eng. A, 2015, 640, p 436–442

M.A. Meyers, Y.B. Xu, Q. Xue, M.T. Perez-Prado, and T.R. McNelley, Microstructural Evolution in Adiabatic Shear Localization in Stainless Steel, Acta Mater., 2002, 51, p 1307–1325

A.A. Tiamiyu, R. Basu, A.G. Odeshi, and J.A. Szpunar, Plastic Deformation in Relation to Microstructure and Texture Evolution in AA 2017-T451 and AA 2624-T351 Aluminum Alloys Under Dynamic Impact Loading, Mater. Sci. Eng., A, 2015, 636, p 379–388

M.T. Pérez-Prado, J.A. Hines, and K.S. Vecchio, Microstructural Evolution in Adiabatic Shear Bands in Ta and Ta–W Alloys, Acta Mater., 2001, 49, p 2905–2917

B.F. Wang, J.Y. Sun, X.Y. Wang, and A. Fu, Adiabatic Shear Localization in a Near Beta Ti–5Al–5Mo–5 V–1Cr–1Fe Alloy, Mater. Sci. Eng., A, 2015, 639, p 526–533

L.E. Murr, A.C. Ramirez, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, D.H. Hernandez, and E. Martinez, Microstructure Evolution Associated with Adiabatic Shear Bands and Shear Band Failure in Ballistic Plug Formation in Ti–6Al–4 V Targets, Mater. Sci. Eng., A, 2009, 516, p 205–216

D.B. Witkin and E.J. Lavernia, Synthesis and Mechanical Behavior of Nanostructured Materials Via Cryomilling, Prog. Mater Sci., 2006, 51, p 1–60

T. Hu, K. Ma, T.D. Topping, J.M. Schoenung, and E.J. Lavernia, Precipitation Phenomena in an Ultrafine-Grained Al Alloy, Acta Mater., 2013, 61, p 2163–2178

K. Ma, H.M. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, and J.M. Schoenung, Mechanical Behavior and Strengthening Mechanisms in Ultrafine Grain Precipitation-Strengthened Aluminum Alloy, Acta Mater., 2014, 62, p 141–155

L.W. Meyer and S. Manwaring, Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena, Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena, L.E. Murr, K.P. Staudhammer, and M.A. Meyers, Ed., Dekker, NewYork, 1986, p 657–674

U. Andrade, M.A. Meyers, K.S. Vecchio, and A.H. Chokshi, Dynamic Recrystallization in High-Strain, High-Strain-Rate Plastic Deformation of Copper, Acta Metall. Mater., 1994, 42, p 3183–3195

B.F. Wang, R. Ma, J.D. Zhou, Z.Z. Li, S.T. Zhao, and X.X. Huang, Adiabatic Shear Localization in Ultrafine Grained 6061 Aluminum Alloy, Mater. Sci. Eng., A, 2016, 675, p 221–227

Q. Li, Y.B. Xu, Z.H. Lai, L.T. Shen, and Y.L. Bai, Dynamic Recrystallization Induced by Plastic Deformation at High Strain Rate in a Monel Alloy, Mater. Sci. Eng., A, 2000, 276, p 250–256

M.A. Meyers, Dynamic Behavior of Materials, Wiley-Interscience, New York, 1994

R.S. Culver, Metallurgical Effects at High Strain Rates, Metallurgical Effects at High Strain Rates, R.W. Rohde, B.M. Butcher, and J.R. Holland, Ed., Plenum Press, New York, 1973, p 519–523

M.A. Lebyodkin, N.P. Kobelev, Y. Bougherira, D. Entemeyer, C. Fressengeas, T.A. Lebedkina, and I.V. Shashkov, On the Similarity of Plastic Flow Processes During Smooth and Jerky Flow in Dilute Alloys, Acta Mater., 2012, 60, p 844–850

A. Vinogradov and A. Lazarev, Continuous Acoustic Emission During Intermittent Plastic Flow in Alpha-Brass, Scripta Mater., 2012, 66, p 745–748

C.Y. Cui, T. Jin, and X.F. Sun, Effects of Heat Treatments on the Serrated Flow in a Ni–Co–Cr-Base Superalloy, J. Mater. Sci., 2011, 46, p 5546–5552

C.L. Hale, W.S. Rollings, and M.L. Weaver, Activation Energy Calculations for Discontinuous Yielding in Inconel 718SPF, Mater. Sci. Eng., A, 2001, 300, p 153–164

W.S. Lee and Z.C. Tang, Relationship Between Mechanical Properties and Microstructural Response of 6061-T6 Aluminum Alloy Impacted at Elevated Temperatures, Mater. Des., 2014, 58, p 116–124

D.H. Li, Y. Yang, T. Xu, H.G. Zheng, Q.S. Zhu, and Q.M. Zhang, Observation of the Microstructure in the Adiabatic Shear Band of 7075 Aluminum Alloy, Mater. Sci. Eng., A, 2010, 527, p 3529–3535

N. Du, A.F. Bower, and P.E. Krajewski, Numerical Simulations of Void Growth in Aluminum Alloy AA5083 During Elevated Temperature Deformation, Mater. Sci. Eng., A, 2010, 527, p 4837–4846

Acknowledgments

This work was financial supported by State Key Laboratory of Powder Metallurgy, Central South University, by National Natural Science of China (No. 51771231), and by the Freedom Explore Program of Central South University (No. 2017zzts426). The authors would like to express their sincere thanks to Professor M. A. Meyers at University of California, San Diego, for good suggestions and help. The authors would like to express their sincere thanks to Professor Yang Wang and Yu Wang at University of Science and Technology of China and Professor Xiang Zan at Hefei University of Technology for dynamic testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, R., Wang, B., Zhang, X. et al. Adiabatic Shear Localization and Microstructure in Ultrafine Grained Aluminum Alloy at Cryogenic Temperature. J. of Materi Eng and Perform 27, 1217–1223 (2018). https://doi.org/10.1007/s11665-018-3157-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3157-5