Abstract

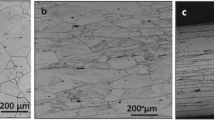

This study investigates the correlation between the residual stress and distortion behavior of a cold-rolled ring from the annealing to quenching-tempering (QT) process. Due to the cold-rolled process, the external periphery of the bearing ring experiences a compressive residual stress. To relieve the residual stress, cold-rolled rings are annealed at 700 °C which is higher than the starting temperature of recrystallization. When cold-rolled rings are annealed at 700 °C for 15 min, the compressive residual stress is reduced to zero and the outer diameter of the annealed ring becomes larger than that of a non-annealed sample, which is unrelated to annealing time. Simultaneously, the roundness and taper deviation do not obviously change compared with those of non-annealed sample. The stress relaxation during the annealing process was attributed to the recovery and recrystallization of ferrite. Annealing has a genetic influence on the following QT heat treatment, wherein the lowest residual stress is in the non-annealed cold-rolled ring. From the annealing to QT process, the deviation of the outer diameter, roundness, and taper increased with annealing time, a large extend than that of non-annealed samples.

Similar content being viewed by others

References

L. Hua, J.D. Deng, and D.S. Qian, Recent Development of Ring Rolling Theory and Technique, Int. J. Mater. Prod. Technol., 2017, 54, p 65–86

J.M. Allwood, T.A. Erman, and T.F. Stanistreet, The Development of Ring Rolling Technology, Steel Res. Int., 2005, 76, p 111–120

J.M. Allwood, T.A. Erman, and T.F. Stanistreet, The Development of Ring Rolling Technology—Part 2: Investigation of Process Behaviour and Production Equipment, Steel Res. Int., 2005, 76, p 491–507

L. Hua and Z.Z. Zhao, The Extremum Parameters in Ring Rolling, J. Mater. Process. Tech., 1997, 69, p 273–276

D.S. Qian, L. Hua, and L.B. Pan, Research on Gripping Conditions in Profile Ring Rolling of Raceway Groove, J. Mater. Process. Tech., 2009, 209, p 2794–2802

H. Yang, L.G. Guo, and M. Zhan, Role of Friction in Cold Ring Rolling, J. Mater. Process. Tech., 2005, 21, p 914–920

X.H. Han and L. Hua, Plastic Deformation Behaviors and Mechanical Properties of Rolled Rings of 20CrMnTi Alloy in Combined Radial and Axial Ring Rolling, Mater. Des., 2014, 58, p 508–517

H. Utsunomiya, Y. Saito, T. Shinoda, and I. Takasu, Elastic–Plastic Finite Element Analysis of Cold Ring Rolling Process, J. Mater. Process. Tech., 2002, 125–126, p 613–618

Y. Yea, Y. Ko, N. Kim, and J. Lee, Prediction of Spread, Pressure Distribution and Roll Force in Ring Rolling Process Using Rigid–Plastic Finite Element Method, J. Mater. Process. Tech., 2003, 140, p 478–486

X.H. Han and L. Hua, Effect of Friction on Combined Radial and Axial Ring Rolling Process, Tribol. Int., 2014, 73, p 117–127

D.S. Qian and L. Hua, Blank Design Optimization for Stepped-Section Profile Ring Rolling, Sci. China. Technol. Sci., 2010, 53, p 1612–1619

K.D. Thoben and D. Klein, A System-Oriented View on the Distortion of Component-Parts, Heat Treat. Met., 2004, 11, p 43–50

H.W. Zoch, From Single Production Step to Entire Process Chain—The Global Approach of Distortion Engineering, Mat.-wiss. u. Werkstofftech., 2006, 37, p 6–7

A.D. Silva, T.A. Pedrosa, M.J.L. Gonzalez, X. Jiang, P.R. Cetlin, and T. Altan, Distortion in Quenching an AISI 4140 C-Ring—Predictions and Experiments, Mater. Des., 2012, 42, p 55–61

H. Surm, O. Kessler, F. Hoffmann, and P. Mayr, Effect of Machining and Heating Parameters on Distortion of AISI 52100 Steel Bearing Rings, J. Mater. Process. Tech., 2005, 24, p 1–4

J. Epp, H. Surm, T. Hirsch, and F. Hoffmann, Residual Stress Relaxation During Heating of Bearing Rings Produced in Two Different Manufacturing Chains, J. Mater. Process. Tech., 2011, 211, p 637–643

J. Epp, H. Surm, T. Hirsch, and F. Hoffmann, Interdependence of Distortion and Residual Stress Relaxation of Cold-Rolled Bearing Rings During Heating, Metall. Mater. Trans. A, 2011, 42A, p 1205–1214

M. Eskandari, M.A. Mohtadi-Bonab, and J.A. Szpunar, Evolution of the Microstructure and Texture of X70 Pipeline Steel During Cold-Rolling and Annealing Treatments, Mater. Des., 2016, 90, p 618–627

F. Frerichs, T. Lübben, and F. Hoffmann, Distortion of Conical Formed Bearing Rings Made of SAE 52100, Mat.-wiss. u. Werkstofftech., 2009, 40, p 402–407

K. Ryttberg, M.K. Wedel, V. Recina, P. Dahlman, and L. Nyborg, The Effect of Cold Ring Rolling on the Evolution of Microstructure and Texture in 100Cr6 Steel, Mat. Sci. Eng. A., 2010, 527, p 2431–2436

L. Nowag, J. Sölter, and E. Brinksmeier, Influence of Turning Parameters on Distortion of Bearing Rings, Prod. Eng., 2007, 1, p 135–139

H. Surm, F. Frerichs, and T. Lübben, Distortion of Rings Due to Inhomogeneous Temperature Distribution, Mat.-wiss. u. Werkstofftech., 2012, 43, p 29–36

L.N. Brewer, M.A. Othon, and L.M. Young, Misorientation Mapping for Visualization of Plastic Deformation Via Electron Back-Scattered Diffraction, Microsc. Microanal., 2006, 12, p 85–91

O. Vöhringer, Relaxation of Residual Stresses by Annealing or Mechanical Treatment, Residual Stress, 1987, 4, p 367–396

M. Furukawa, Y. Iwahashi, and Z. Horita, Structural Evolution and the Hall–Petch Relationship in an Al-Mg-Li-Zr Alloy with Ultra-Fine Grain Size, Acta Mater., 1997, 45, p 4751–4757

L.D.C.F. Canale and E.T. George, Overview of Distortion and Residual Stress Due to Quench Processing Part I: Factors Affecting Quench Distortion, Int. J. Mater. Prod. Technol., 2005, 24, p 1–4

Acknowledgments

The authors would like to appreciate the National Natural Science Foundation of China (Grant No. 51575414), the China Postdoctoral Science Foundation (No. 2017M612524), and the Important Science and Technology Innovation Program of Hubei Province (No. 2015AAA005) for the support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, B., Lu, X. Evolution of Residual Stress and Distortion of Cold-Rolled Bearing Ring from Annealing to Quenched-Tempered Heat Treatment. J. of Materi Eng and Perform 27, 368–378 (2018). https://doi.org/10.1007/s11665-017-3119-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3119-3