Abstract

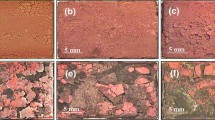

The corrosion behaviors of Super304H and HR3C used for USC boiler applications were investigated in simulated coal ash/gas environments with 0.1 and 1.5% of SO2 at 650 °C for 500 h. The results indicated that the increase in SO2 accelerated the corrosion rate and the spalling tendency of the corrosion layer in both tested alloys. Fe2O3, Cr2O3 and FeCr2O4 main peaks were revealed by XRD on Super304H, but on HR3C only the Cr2O3 peak showed a high intensity. The SO2 content did not affect the corrosion product composition of any of the alloys, but accelerated the inner sulfidation and the spallation on Super304H. No obvious internal sulfidation was observed on HR3C in either SO2 content. Based on the experimental results, the alloy corrosion mechanism and the influence of sulfur content on the corrosion process were discussed.

Similar content being viewed by others

References

F. Abe, Research and Development of Heat-Resistant Materials for Advanced USC Power Plants with Steam Temperatures of 700 °C and Above, Eng. Sci., 2015, 1(2), p 211–224

R. Viswanathan, J.F. Henry, J. Tanzosh, G. Stanko, and J. Shingledecker, US Program on Materials Technology for Ultra-Supercritical Coal Power Plants, ASME Press. Vessels Pip. Conf., 2007, 14(3), p 281–292

L. Zhou, G. Xu, S. Zhao, C. Xu, and Y. Yang, Parametric Analysis and Process Optimization of Steam Cycle in Double Reheat Ultra-Supercritical Power Plants, Appl. Therm. Eng., 2016, 99, p 652–660

R. Viswanathan and W. Bakker, Materials for Ultra Supercritical Coal Power Plants—Boiler Materials: Part 1, J. Mater. Eng. Perform., 2015, 10(1), p 81–95

R. Viswanathan, W. Bakker, Materials for Boilers in Ultra Supercritical Power Plants, in Proceedings of 2000 International Joint Power Generation Conference, Miami Beach, Florida, July 23–26, 2000, p. 1–22.

K. Natesan and J.H. Park, Fireside and Steamside Corrosion of Alloys for USC Plants, Int. J. Hydrogen Energy, 2007, 32(16), p 3689–3697

M.S. Gagliano, H. Hack, G. Stanko, Update on the Fireside Corrosion Resistance of Proposed Advanced Ultrasupercritical Superheater and Reheater Materials: Laboratory and Field Test Results, in The 2009 Clearwater Coal Conference and 34th International Technical Conference on Coal Utilization and Fuel Systems. Clearwater, USA, May 31–June 4, 2009.

S. Gosia, D.M. Flórez, J. Maier, and G. Scheffknecht, Nickel-Base Superalloys for Ultra-Supercritical Coal-Fired Power Plants: Fireside Corrosion: Laboratory Studies and Power Plant Exposures, Fuel, 2013, 108, p 521–533

B. Rutkowski, A. Gil, and A. Czyrska-Filemonowicz, Microstructure and Chemical Composition of the Oxide Scale Formed on the Sanicro 25 Steel Tubes After Fireside Corrosion, Corros. Sci., 2016, 102, p 373–383

T. Tokairin, K.V. Dahl, and H.K. Danielsen, Investigation on Long-Term Creep Rupture Properties and Microstructure Stability of Fe-Ni Based Alloy Ni-23Cr-7W at 700 °C, Mater. Sci. Eng., A, 2013, 565, p 285–291

N. Otsuka, Fireside Corrosion of Austenitic Tube Materials for Advanced USC Boilers, Mater. Sci. Forum, 2011, 696, p 206–211

R.E. Pawelt and J.J. Campbell, Cation Vacancy Concentrations in Ferrous Sulfide Containing Chromium and Manganese, Oxid. Met., 1986, 26(3–4), p 253–261

Acknowledgments

The authors would like to gratefully acknowledge the financial support provided by the National Natural Science Foundation of China (Grant Numbers 51301130 and 51401163). Part of the funding was provided by the research program of the China Huaneng Group.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, J., Yang, Z., Li, Y. et al. Fireside Corrosion Behaviors of Super304H and HR3C in Coal Ash/Gas Environment with Different SO2 Contents at 650 °C. J. of Materi Eng and Perform 27, 2855–2862 (2018). https://doi.org/10.1007/s11665-017-3051-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3051-6