Abstract

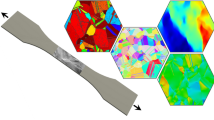

Nimonic 101 is one of the early nickel-based superalloys developed for the use in gas turbines. In such environments, the material is exposed to a combination of both high temperatures and mechanical loads for a long duration. Hence, thermal creep is of the utmost concern as it often limits service life. This study focuses on creep tests, carried out on Nimonic 101 at different temperatures under a constant tensile load of 735 MPa. To characterize the microstructural evolution, electron backscatter diffraction (EBSD) measurements were employed before and after loading. At higher temperatures, a significant change of the microstructure was observed. The grains elongated and aligned their orientation along the load axis. In parallel, a crystal plasticity material model has been set up in the classical large deformation framework. Modeling results are compared to the acquired EBSD data.

Similar content being viewed by others

Change history

11 March 2020

The original article has been corrected.

11 March 2020

The original article has been corrected.

References

C. Lechner and J. Seume, Stationäre Gasturbinen (Stationary Gas Turbines), Springer, Berlin, 2010 (in German)

T.M. Pollock and S. Tin, Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure, and Properties, J. Propuls. Power, 2006, 22(2), p 361-374

K.H. Kloos, J. Granacher, and Th Windecker, Hochtemperaturverhalten von Werkstoffen aus Neuartig Gefertigten Gasturbinenschaufeln, Mat. Wiss. Werkstofftech., 1994, 25, p 235-243 (in German)

R.W. Kozar, A. Suzuki, W.W. Milligan, J.J. Schirra, M.F. Savage, and T.M. Pollock, Strengthening Mechanisms in Polycrystalline Multimodal Nickel-Base Superalloys, Metall. Mater. Trans. A, 2009, 40A, p 1588-1603

A. Raffaitin, D. Monceau, F. Crabos, and E. Andrieu, The Effect of Thermal Cycling on the High-Temperature Creep Behavior of a Single Crystal Nickel-Based Superalloy, Scr. Mater., 2007, 56(4), p 277-280

G.J. Pataky, H. Sehitoglu, and H.J. Maier, Creep Deformation and Mechanisms in Haynes 230 at 800 and 900 °C, J. Nucl. Mater., 2013, 443, p 484-490

B.F. Dyson and T.B. Gibbons, Tertiary Creep in Nickel-Base superalloys: Analysis of Experimental Data and Theoretical Synthesis, Acta Met., 1987, 35(9), p 2355-2369

R. Sharghi-Moshtaghin and S. Asgari, The Influence of Thermal Exposure on the γ′ Precipitates Characteristics and Tensile Behavior of Superalloy IN-738LC, J. Mater. Process. Technol., 2004, 147, p 343-350

A. Nitz, U. Lagerpusch, and E. Nembach, CRSS Anisotropy and Tension/Compression Asymmetry of a Commercial Superalloy, Acta Mater., 1998, 46(13), p 4769-4779

W. Hoffelner, E. Kny, R. Strickler, and W.J. McCall, Effects of Aging Treatments on the Microstructure of the Ni-Base Superalloy IN-738, Z. Werkstofftech., 1979, 10, p 84-92

R.A. Stevens and P.E.J. Flewitt, The Effects of γ′ Precipitate Coarsening During Isothermal Aging and Creep of the Nickel-Base Superalloy IN-738, Mater. Sci. Eng., 1979, 37, p 237-247

A. Wisniewski and J. Beddoes, Influence of Grain Boundary Morphology on Creep of a Wrought Ni-Based Superalloy, Mater. Sci. Eng. A, 2009, 2009, p 510-511

R.K. Mishra and R. Kubic, Jr., In Situ EBSD of Microstructure Evolution During Deformation, Microsc. Microanal., 2008, 14, p 552-553

D. Kobayashi, M. Miyabe, Y. Kagiya, R. Sugiura, and A.T. Yokobory, Jr., An Assessment and Estimation of the Damage Progression Behavior of IN738LC Under Various Applied Stress Conditions Based on EBSD Analysis, Metall. Mater. Trans. A, 2013, 44A, p 3123-3135

S.I. Wright, M.M. Nowell, and D.P. Field, A Review of Strain Analysis Using Electron Backscatter Diffraction, Microsc. Microanal., 2011, 17, p 316-329

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe, Overview of Constitutive Laws, Kinematics, Homogenization and Multiscale Methods in Crystal Plasticity Finite-Element Modelling: Theory, Experiments, Applications, Acta Mater., 2010, 58(4), p 1152-1211

E. Lehmann, D. Faßmann, S. Löhnert, M. Schaper, and P. Wriggers, Texture Development and Formability Prediction for Pre-textured Cold Rolled Body-centred Cubic Steel, Int. J. Eng. Sci., 2013, 68, p 24-37

D. Raabe, Z. Zhao, and W. Mao, On the Dependence of in-Grain Subdivision and Deformation Texture of Aluminum on Grain Interaction, Acta Mater., 2002, 50(17), p 4379-4394

J.-B. le Graverend, J. Cormier, F. Gallerneau, P. Villechaise, S. Kruch, and J. Mendez, A Microstructure-Sensitive Constitutive Modeling of the Inelastic Behavior of Single Crystal Nickel-Based Superalloys at Very High Temperature, Int. J. Plast., 2014, 59, p 55-83

M. Shenoy, Y. Tjiptowidjojo, and D. McDowell, Microstructure-Sensitive Modeling of Polycrystalline IN 100, Int. J. Plast., 2008, 24(10), p 1694-1730

R. MacKay and R.D. Maier, The Influence of Orientation on the Stress Rupture Properties of Nickel Base Superalloy Single Crystals, Metall. Trans. A, 1982, 13A, p 1747-1754

J. Preußner, Y. Rudnik, H. Brehm, R. Völkl, and U. Glatzel, A Dislocation Density Based Material Model to Simulate the Anisotropic Creep Behaviour of Single-Phase and Two-Phase Single Crystals, Int. J. Plast., 2009, 25(5), p 973-994

I.N. Vladimirov, S. Reese, and G. Eggeler, Constitutive Modelling of the Anisotropic Creep Behaviour of Nickel-Base Single Crystal Superalloys, Int. J. Mater. Sci., 2009, 51, p 305-313

A.W. Judge, Small Gas Turbines and Free Piston Engines, Chapman & Hall Ltd, London, 1960, p 328

S. Straub, W. Bluhm, H.J. Maier, T. Ungar, A. Borbély, and H. Renner, Long-Range Internal Stresses in Cell and Subgrain Structures of Copper During Deformation at Constant Stress, Acta Mater., 1996, 44(11), p 4337-4350

O. Diard, S. Leclercq, G. Rousselier, and G. Cailletaud, Evaluation of Finite Element Based Analysis of 3D Multicrystalline Aggregates Plasticity: Application to Crystal Plasticity Model Identification and the Study of Stress and Strain Fields Near Grain Boundaries, Int. J. Plast., 2005, 21(4), p 691-722

D.H. Chung and W.R. Buessem, The Elastic Anisotropy of Crystals, J. Appl. Phys., 1967, 38(5), p 2010-2012

B.F. Dyson, Micromechanism-Quantification for Creep Constitutive Equations. in IUTAM Symposium on Creep in Structures, p. 3-16 (2001)

A.M. Cuitino and M. Ortiz, Constitutive Modeling of L12 Intermetallic Crystals, Mater. Sci. Eng. A, 1993, 170, p 111-123

B.F. Dyson, Microstructure Based Creep Constitutive Model for Precipitation Strengthened Alloys: Theory and Application, Mater. Sci. Technol., 2009, 25(2), p 213-220

X. Feaugas, On the Origin of the Tensile Flow Stress in the Stainless Steel AISI, 316L at 300K: Backstress and Effective Stress, Acta Metall., 1999, 47(13), p 3617-3632

L. Kubin and B. Devincre, Toward a physical model for strain hardening in fcc crystals, Mater. Sci. Eng. A, 2008, 483-484, p 19-24

P. Franciosi and A. Zaoui, Multislip Tests on Copper crystals: A Junctions Hardening Effect, Acta Metall., 1982, 30, p 2141-2151

N. Matan, D.C. Cox, P. Carter, M.A. Rist, C.M.F. Rae, and R.C. Reed, Creep pf CMSX-4 Superalloy Single Crystals: Effects of Misorientation and Temperature, Acta Mater., 1999, 45(5), p 1549-1563

J.R. Rice, Inelastic Constitutive Relations for Solids: An Internal-Variable Theory and Its Application to Metal Plasticity, J. Mech. Phys. Solids, 1971, 19, p 433-455

A. Bertram, Finite Thermoplasticity Based on Isomorphisms, Int. J. Plast., 2003, 19(11), p 2027-2050

J. Korelc and P. Wriggers, Automation of Finite Element Methods, Springer, Berlin, 2016

C.H. da Silva Santos, M.S. Gonçalves, and H.E. Hernandez-Figueroa, Designing Novel Photonic Devices by Bio-Inspired Computing, IEEE Photon. Technol. Lett., 2010, 15(22), p 1177-1179

S.G. Johnson, The NLopt Nonlinear-Optimization Package. https://ab-initio.mit.edu/nlopt, Version 2.4.2

R. Quey, P.R. Dawson, and F. Barbe, Large-Scale 3D Random Polycrystals for the Finite Element Method: Generation, Meshing and Remeshing, Comput. Method. Appl. Mech. Eng., 2011, 200(17-20), p 1729-1745

A.M. Borzdyka, L.B. Gecov, Relaxation of Stresses in Metals and Alloys. in Metallurgy, Moscow, p. 304 (1972) (in Russian)

W. Hermann, H.G. Sockel, J. Han, and A. Bertram, Elastic Properties and Determination of Elastic Constants of Nickel-Base Superalloys by a Free-Free Beam Technique, Superalloys, 1996, 5, p 229-238

G.B. Viswanathan, P.M. Sarosi, D.H. Whitis, and M.J. Mills, Deformation Mechanisms at Intermediate Creep Temperatures in the Ni-Base Superalloy René 88 DT, Mater. Sci. Eng. A, 2005, 400, p 489-495

R.R. Unocic, G.B. Viswanathan, P.M. Sarosi, S. Karthikeyan, J. Li, and M.J. Millis, Mechanisms of Creep Deformation in Polycrystalline Ni-Base Disk Superalloys, Mater. Sci. Eng. A, 2008, 483, p 25-32

M.I. Alymov, A.I. Epishin, G. Nolze, T. Link, S.S. Bedov, and A.B. Ankudinov, Electron Microscopy Investigation of the Structure of a Compact Extruded from Nanopowder of Nickel, Russian Nanotechnol., 2007, 2, p 124-129 (in Russian)

Y.M. Vainblat, T.B. Sagalova, and L.B. Ber, Fibrous Structure and Texture of Extruded Rods of Alloy AK8, Metalloved. Term. Obrab. Metalloved., 1969, 2, p 31-34

G. Lin and K.S. Havner, On the Evolution of Texture and Yield Loci in Axisymmetric Deformation of FCC Polycrystals, Int. J. Plast., 1994, 10(5), p 471-498

T. Böhlke, G. Risy, and A. Bertram, A Texture Component Model for Anisotropic Polycrystal Plasticity, Comput. Mater. Sci., 2005, 32, p 284-293

H.J. Bunge, Some Applications of the Taylor Theory of Polycrystal Plasticity, Krist. Tech., 1970, 5(1), p 145-175

D.M. Knowles and S. Gunturi, The Role of 〈112〉{111} Slip in the Asymmetric Nature of Creep of Single Crystal Superalloy CMSX-4, Mater. Sci. Eng., 2002, 328, p 223-237

V. Sass and U. Glatzel, Anisotropic Creep Properties of the Nickel-Base Superalloy CMSX-4, Acta Metall., 1996, 44, p 1967-1977

Q. Qin and V. Bassani, Non-schmid Yield Behavior in Single Crystals, J. Mech. Phys. Solids, 1992, 40(4), p 813-833

Acknowledgments

Financial support of this study by the German Science Foundation (DFG) under contracts MA1175/63-1 and WR19/57-1 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reschka, S., Munk, L., Wriggers, P. et al. An EBSD Evaluation of the Microstructure of Crept Nimonic 101 for the Validation of a Polycrystal–Plasticity Model. J. of Materi Eng and Perform 26, 6087–6098 (2017). https://doi.org/10.1007/s11665-017-3046-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3046-3