Abstract

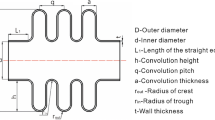

Tensile tests of original plate samples from three types of stainless steel metal bellows were performed at room temperature. The constitutive equations for the three hardening curves were obtained and fitted. The analysis results of the microstructure and fracture morphology of the tensile specimens show that the grain size of the plate with a high logarithmic–exponential hardening rate is uneven and the dimple of the shear fracture is elongated into an ellipse. By contrast, the grain size of the plate with a relatively low linear hardening rate is even and the dimple of the fracture is uniformly equiaxial. Finite element simulations of the hydraulic bulging and repeated limit bending deformation of the metal bellows of the three types of materials were also conducted. The repeated limit bending deformation process was tested experimentally. Although the effect of the hardening exponent on the residual stress of the metal bellows after hydraulic bulging is minimal, this exponent considerably influences the repeated limit bending deformation of the metal bellows after subsequent use. The trough hardening phenomenon is serious in the repeated limit bending process. Moreover, when the hardening exponent of the original plate is high, the resistance to bending fracture at the trough area is poor.

Similar content being viewed by others

References

M. Ziętala, T. Durejko, M. Polański et al., The Microstructure, Mechanical Properties and Corrosion Resistance of 316L Stainless Steel Fabricated Using Laser Engineered Net Shaping, Mater. Sci. Eng., A, 2016, 677, p 1–10

I. Dayyani, A.D. Shaw, E.I.S. Flores et al., The Mechanics of Composite Corrugated Structures: A Review with Applications in Morphing Aircraft, Compos. Struct., 2015, 133(1), p 358–380

Y.Z. Zhu, H.F. Wang, and Z.F. Sang, The Effect of Environmental Medium on Fatigue Life for u-Shaped Bellows Expansion Joints, Int. J. Fatigue, 2006, 28(1), p 28–32

H.Y. Yi, F.K. Yan, N.R. Tao et al., Work Hardening Behavior of Nanotwinned Austenitic Grains in a Metastable Austenitic Stainless Steel, Scr. Mater., 2016, 114, p 133–136

A. Belattar, C. Keller, and L. Taleb, Multiscale Analysis of the Pre-hardening Effect on the Cyclic Behavior and Fatigue Life of 304L Stainless Steel, Mater. Sci. Eng., A, 2016, 662, p 468–480

Z.J. Wang, N. Xiang, J. Yi et al., Forming Thin-Walled Circular Rings with Corrugated Meridians Via Quasi-Bulk Deformation of Metal Blank and Viscous Medium, J. Mater. Process. Technol., 2016, 236, p 35–47

J. Wang, H. Ma, Q. Zhu et al., Numerical and Experimental Investigation of Pulsating Heat Pipes with Corrugated Configuration, Appl. Therm. Eng., 2016, 102, p 158–166

A. Márquez, P.G. Fazzini, and J.L. Otegui, Failure Analysis of Flexible Metal Hose at Compressor Discharge, Eng. Fail. Anal., 2009, 16(6), p 1912–1921

R. Steinheimer and B. Engel, Thermal Influences During Rotary Draw Bending of Tubes from Stainless Steel, Procedia Eng., 2014, 81, p 2165–2170

W.W. Zhang and S. Cong, Failure Analysis of SUS304 Sheet During Hydro-bulging Based on GTN Ductile Damage Model, Int. J. Adv. Manuf. Technol., 2016, 1, p 1–9

E. Daxin and R. Li, Influence of Additional Tensile Force on the Stress and Deformation of Numerically Controlled Tube Bending, Int. J. Adv. Manuf. Technol., 2015, 78(5), p 895–905

J. Christopher and B.K. Choudhary, On the Assessment of Tensile Work Hardening Behaviour of Type 316L(N) Austenitic Stainless Steel in the Framework of θσ d, vs. σ d, Using Flow Stress Contribution from Dislocations, Int. J. Press. Vessels Pip., 2016, 146(10), p 151–160

X. Qin and D. Gao, The Effect of Residual Bending on Coiled Tubing Buckling Behavior in a Horizontal Well, J. Nat. Gas Sci. Eng., 2016, 30, p 182–194

E. Silvestre, J. Mendiguren, L. Galdos et al., Comparison of the Hardening Behaviour of Different Steel Families: From Mild and Stainless Steel to Advanced High Strength Steels, Int. J. Mech. Sci., 2015, 101–102(4), p 10–20

J. Ding, G. Kang, Y. Zhu et al., Finite Element Analysis on Bending Fretting Fatigue of 316L Stainless Steel Considering Ratchetting and Cyclic Hardening, Int. J. Mech. Sci., 2014, 86(6), p 26–33

H. Hachemi, H. Kebir, J.M. Roelandt et al., A Study of the Braided Corrugated Hoses: Behavior and Life Estimation, Mater. Des., 2011, 32(4), p 1957–1966

J.F. Peng, C. Song, M.X. Shen et al., An Experimental Study on Bending Fretting Fatigue Characteristics of 316L Austenitic Stainless Steel, Tribol. Int., 2011, 44(11), p 1417–1426

E. Donnelly, F.M. Weafer, T. Connolley et al., Experimental Investigation into the Size Effect on the Microscale Fatigue Behaviour of 316L Stainless Steel, Int. J. Fatigue, 2017, 95, p 1–7

M. Azadeh and F. Taheri, On the Response of Dented Stainless-Steel Pipes Subject to Cyclic Bending Moments and Its Prediction, Thin Walled Struct., 2016, 99, p 12–20

V. Shlyannikov, A. Tumanov, A. Zakharov et al., Surface Flaws Behavior Under Tension, Bending and Biaxial Cyclic Loading, Int. J. Fatigue, 2016, 92, p 557–576

Acknowledgments

This project is supported by National Natural Science Foundation of China (Grant No. 51775479) and Natural Science Foundation of Hebei Province, China (Grant No. E2017203046).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, Z., Luo, S., Zhao, H. et al. Effect of Plate Hardening Behavior on the Deformation of Stainless Steel Metal Bellows. J. of Materi Eng and Perform 26, 5385–5395 (2017). https://doi.org/10.1007/s11665-017-3013-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3013-z