Abstract

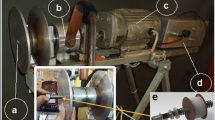

This paper describes the details of design, manufacture and testing of 200 mm diameter spherical gas bottle of Inconel 718 (IN718) with nominal wall thickness of 2.3 mm. Gas bottle was designed for the specified internal pressure loading with a thickness of 2.9 mm at the circumferential weld which was brought down to 2.3 mm at the membrane locations. Hemispherical forgings produced through closed-die hammer forging were machined and electron beam welded to produce a spherical gas bottle. Duly welded gas bottle was subjected to standard aging treatment to achieve the required tensile strength. Aged gas bottle was inspected for dimensions and other stringent quality requirements using various nondestructive testing techniques. After inspection, gas bottle was subjected to pressure test for maximum expected operating pressure and proof pressure of 25 and 37.5 MPa, respectively. Strain gauges were bonded at different locations on the gas bottle to monitor the strains during the pressure test and correlated with the predicted values. The predicted strain matched well with the experimental strain confirming the design and structural integrity.

Similar content being viewed by others

References

J. Benton, I. Ballinger, D.E. Jaekle Jr., and M.F. Osborn, Design and Manufacture of a Propellant Tank Assembly, in 43rd Joint Propulsion Conference Exhibit. Cincinnati OH (2007).

C. Clauss, Design, Qualification, and Thermal Testing of a Specialized Composite Overwrap Pressure Vessel (COPV) AIAA-2007-5558, (2007), pp. 1–10.

A.K. Jha, S.V.S.N. Murty, K. Sreekumar, and P.P. Sinha, High Strain Rate Deformation and Cracking of AA 2219 Aluminium Alloy Welded Propellant Tank, Eng. Fail. Anal., 2009, 16, p 2209–2216

S.K. Singh, P. Muneshwar, K.N. Kumar, B. Pant, K. Sreekumar, and P.P. Sinha, Development and Characterization of Ti5Al2·5Sn-eli Alloy Hemispherical Domes for High-Pressure Cold Helium Tanks, Mater. Sci. Forum, 2012, 710, p 113–118

A.K. Jha, V. Diwakar, B. Pant, and K. Sreekumar, Failure Analysis of a Ti-6Al-4V Gas Bottle, Eng. Fail. Anal., 2006, 13, p 843–856. doi:10.1016/j.engfailanal.2005.02.011

P. Muneshwar, S.K. Singh, B. Pant, S.C. Sharma, and M.C. Mittal, Advanced Processing Techniques for Titanium Base Alloys and its Aluminides for Space Applications, Trans. Indian Inst. Metals, 2008, 61, p 77–85. doi:10.1007/s12666-008-0008-3

F.R. Schwartzberg, and J.A. Shepic, Effect of High-Pressure Oxygen on the Mechanical Properties of Alloys. NASA-CR-150137 (1977).

S. Chenna Krishna, G.S. Rao, S.K. Singh, S.V.S. Narayana Murty, G. Venkatanarayana, A.K. Jha et al., Processing and Characterization of Sub-delta Solvus Forged Hemispherical Forgings of Inconel 718, J. Mater. Eng. Perform., 2016, 25, p 5477–5485. doi:10.1007/s11665-016-2377-9

S.C. Krishna, S.K. Singh, S.V.S.N. Murty, G. Venkata Narayana, A.K. Jha, B. Pant et al., Closed Die Hammer Forging of Inconel 718, J. Metall., 2014, 2014, p 1–7. doi:10.1155/2014/972917

M. Agilan, S.C. Krishna, S.K. Manwatkar, E.G. Vinayan, D. Sivakumar, and B. Pant, Effect of Welding Processes (GTAW & EBW) and Solutionizing Temperature on Microfissuring Tendency in Inconel 718 Welds, Mater. Sci. Forum, 2012, 710, p 603–607. doi:10.4028/www.scientific.net/MSF.710.603

M. Agilan, T. Venkateswaran, D. Sivakumar, and B. Pant, Effect of Heat Input on Microstructure and Mechanical Properties of Inconel-718 EB Welds, Proced. Mater. Sci., 2014, 5, p 656–662. doi:10.1016/j.mspro.2014.07.312

N.L. Svensson, The Bursting Pressure of Cylindrical and Spherical Vessels, J. Appl. Mech., 1958, 25, p 89–96

A. Chamanfar, L. Sarrat, M. Jahazi, M. Asadi, A. Weck, and A.K. Koul, Microstructural Characteristics of Forged and Heat Treated Inconel-718 Disks, Mater. Des., 2013, 52, p 791–800. doi:10.1016/j.matdes.2013.06.004

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, and R. Srinivasan, Modeling Grain Size During Hot Deformation of IN 718, Scr. Mater., 1999, 42, p 17–23. doi:10.1016/S1359-6462(99)00316-4

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, and R. Srinivasan, Microstructural Modeling of Metadynamic Recrystallization in Hot Working of IN 718 Superalloy, Mater. Sci. Eng. A, 2000, 293, p 198–207. doi:10.1016/S0921-5093(00)01053-4

R.G. Thompson, J.J. Cassimus, D.E. Mayo, and J.R. Dobbs, The Relationship Between Grain-Size and Microfissuring in Alloy-718-Microfissuring is Linearly Dependent on Grain-Size, Weld. J., 1985, 64, p S91–S96

R.G. Thompson, J.R. Dobbs, and D.E. Mayo, The Effect of Heat Treatment on Microfissuring in Alloy 718, Weld. J., 1986, 65, p 299

G.D.J. Ram, A.V. Reddy, K.P. Rao, and G.M. Reddy, Microstructure and Mechanical Properties of Inconel 718 Electron Beam Welds, Mater. Sci. Technol., 2005, 21, p 1132–1138. doi:10.1179/174328405X62260

Acknowledgments

The authors would like to thank Dr. K. Sivan Director, Vikram Sarabhai Space Centre, Trivandrum, India, for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chenna Krishna, S., Agilan, M., Sudarshan Rao, G. et al. Design, Development and Testing of Inconel Alloy IN718 Spherical Gas Bottle for Oxygen Storage. J. of Materi Eng and Perform 26, 5355–5365 (2017). https://doi.org/10.1007/s11665-017-2996-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2996-9