Abstract

Microstructure evolution and wear resistance of Stellite 12 produced by laser additive manufacturing were studied in untreated and heat-treated conditions. In untreated conditions, cobalt matrix dendrites and inter-dendritic eutectic carbides were the primary microstructure, blocky and lamellar eutectic carbides can be found, and M7C3 and M23C6 are the primary carbides. Heat treatment can modify the microstructure of this alloy. Primary carbides were dissolved into the cobalt matrix after solution treatment. Aging treatment resulted in the precipitation of carbides, the transformation of M7C3 into M23C6 carbides, and the increase in microhardness. Solution and aging treatment can also cause the precipitation of carbides, but the morphology and distribution of carbides were absolutely different. The wear resistance of untreated samples at room temperature (RT) and 600 °C is better than that at 200 and 400 °C due to the high hardness at RT and the formation of oxide film at 600 °C. The wear resistance of heat-treated samples was tested at 600 °C; it was dominated by the formation and flake-off of oxide film. The sample that underwent solution plus aging treatment has a superior wear resistance.

Similar content being viewed by others

References

W. Gui, H. Zhang, M. Yang, T. Jin, X. Sun, and Q. Zheng, The Investigation of Carbides Evolution in a Cobalt-Base Superalloy at Elevated Temperature, J. Alloy Compd., 2017, 695, p 1271–1278

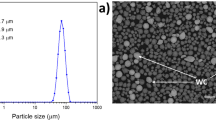

M. Zhong, W. Liu, K. Yao, J.-C. Goussain, C. Mayer, and A. Becker, Microstructural Evolution in High Power Laser Cladding of Stellite 6+WC Layers, Surf. Coat. Tech., 2002, 157, p 128–137

D.W. Deng, C.P. Zhang, R. Chen, and H.F. Xia, Microstructure and Microhardness of 17-4PH DEPOSITED with Co-Based Alloy Hardfacing Coating, Phys. Proced., 2013, 50, p 177–184

R. Ahmed, H.L. de Villiers Lovelock, S. Davies, and N.H. Faisal, Influence of Re-HIPing on the Structure-Property Relationships of Cobalt-Based Alloys, Tribol. Int., 2013, 57, p 8–21

E. Díaz, M.J. Tobar, A. Yáñez, García, and J. Taibo, Laser Powder Welding with a Co-Based Alloy for Repairing Steam Circuit Components in Thermal Power Stations, Phys. Proced., 2010, 5, p 349–358

Y. Tian, A. Gontcharov, R. Gauvin, P. Lowden, and M. Brochu, Effect of Heat Treatments on Microstructure Evolution and Mechanical Properties of Blended Nickel-Based Superalloys Powders Fabricated by Laser Powder Deposition, Mater. Sci. Eng. A, 2016, 674, p 646–657

S. Pu, J. Zhang, Y.F. Shen, and L.H. Lou, Recrystallization in a Directionally Solidified Cobalt-Base Superalloy, Mater. Sci. Eng. A, 2008, 480, p 428–4337

F.M. Yang, X.F. Sun, W. Zhang, Y.P. Kang, H.R. Guan, and Z.Q. Hu, Secondary M6C Precipitation in K40S Cobalt-Base Alloy, Mater. Lett., 2001, 49, p 160–164

W.H. Jiang, H.R. Guan, and Z.Q. Hu, Effects of Heat Treatment on Microstructures and Mechanical Properties of a Directionally Solidified Cobalt-Base Superalloy, Mater. Sci. Eng. A, 1999, 271, p 101–108

C. Cui, Z. Guo, Y. Liu, Q. Xie, Z. Wang, H. Jiandong, and Y. Yao, Characteristics of Cobalt-Based Alloy Coating on Tool Steel Prepared by Powder Feeding Laser Cladding, Opt. Laser Technol., 2007, 39, p 1544–1550

A. Mostafaei, Y. Behnamian, Y.L. Krimer, E.L. Stevens, J. Li, L. Luo, and M. Chmielus, Effect of Solutionizing and Aging on the Microstructure and Mechanical Properties of Powder Bed Binder Jet Printed Nickel-Based Superalloy 625, Mater. Des., 2016, 111, p 482–491

A. Frenk and W. Kurz, Microstructural Effects on the Sliding Wear Resistance of a Cobalt-Based Alloy, Wear, 1994, 174, p 81–91

K.A. Chiang and Y.C. Chen, Microstructural Characterization and Microscopy Analysis of Laser Cladding Stellite12 and Tungsten Carbide, J. Mater. Process. Tech., 2007, 182, p 297–302

R. Arabi Jeshvahani, M. Shanmanian, and M. Jaberzadeh, Enhancement of Wear Resistance of Ductile Iron Surface Alloyed by Stellite 6, Mater. Des., 2011, 32, p 2028–2033

J.R. Lane and N.J. Grant, Carbide Reactions in High Temperature Alloys, Trans. ASM, 1952, 44, p 113–137

W.C. Lin and C. Chen, Characteristics of Thin Surface Layers of Cobalt-Based Alloys Deposited by Laser Cladding, Surf. Coat. Tech., 2006, 200, p 4563–4577

A. Motallebzadeh, E. Atar, and H. Cimenoglu, Sliding Wear Characteristics of Molybdenum Containing Stellite 12 Coating at Elevated Temperatures, Tribol. Int., 2015, 91, p 40–47

P.D. Wood, H.E. Evans, and C.B. Ponton, Investigation into the Wear Behaviour of Tribaloy 400 °C During Rotation as an Unlubricated Bearing at 600 °, Wear, 2011, 44, p 1589–1597

H. So, C.T. Chen, and Y.A. Chen, Wear Behaviours of Laser-Clad Stellite 6, Wear, 1996, 192, p 78–84

H. Kashani, A. Amadeh, and H.M. Ghasemi, Room and High Temperature Wear Behaviors of Nickel and Cobalt Base Weld Overlay Coating on Hot Forging Dies, Wear, 2007, 262, p 800–803

Acknowledgements

This work was supported by the National Nature Science Foundation of China (Grant No. 51104110) and by the Suzhou Science and Technology Bureau, China (Grant Nos. SYG201231 and SYG201642). This work was also supported by the State Key Laboratory of Advanced Processing and Recycling of Non-Ferrous Metals, Lanzhou University of Technology, China (Grant No. SKLAB02014006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, B., Zhang, M., Chen, C. et al. Effect of Heat Treatment on Microstructure and Mechanical Properties of Stellite 12 Fabricated by Laser Additive Manufacturing. J. of Materi Eng and Perform 26, 5404–5413 (2017). https://doi.org/10.1007/s11665-017-2984-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2984-0