Abstract

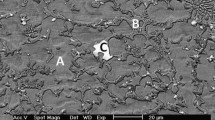

Currently, stainless steel grade 316LN is the material of construction widely used for core catcher of sodium-cooled fast reactors. Design philosophy for core catcher demands its capability to withstand corium loading from whole core melt accidents. Towards this, two ceramic coatings were investigated for its application as a layer of sacrificial material on the top of core catcher to enhance its capability. Plasma-sprayed thermal barrier layer of alumina and partially stabilised zirconia (PSZ) with an intermediate bond coat of NiCrAlY are selected as candidate material and deposited over 316LN SS substrates and were tested for their suitability as thermal barrier layer for core catcher. Coated specimens were exposed to high-temperature thermite melt to simulate impingement of molten corium. Sodium compatibility of alumina and PSZ coatings were also investigated by exposing samples to molten sodium at 400 °C for 500 h. The surface morphology of high-temperature thermite melt-exposed samples and sodium-exposed samples was examined using scanning electron microscope. Phase identification of the exposed samples was carried out by x-ray diffraction technique. Observation from sodium exposure tests indicated that alumina coating offers better protection compared to PSZ coating. However, PSZ coating provided better protection against high-temperature melt exposure, as confirmed during thermite melt exposure test.

Similar content being viewed by others

References

K. Plevacova, C. Journeau, P. Piluso, and J. Poirier, Eutectic Crystallization in the UO2–Al2O3–HfO2 Ceramic Phase Diagram, Ceram. Int., 2014, 40, p 2565–2573

M. Natta, Safety Issues For LMFBRs: Important Features Drawn from the Assessments of Superphénix, in Workshop Proceedings ‘Advanced Nuclear Reactor Safety Issues and Research Needs’, Paris, France, 18–20 Feb 2002, p 103–117

A. Jasmin Sudha, K. Velusamy, and P. Chellapandi, A Multi Layer Core Catcher Concept for Future Sodium Cooled Fast Reactors, Ann. Nucl. Energy, 2014, 65, p 253–261

J.K. Fink, J.J. Heiberger, R. Kumar, R.A. Blomquist, L. Leibowitz, E.S. Sowa, J.R. Pavlik, and L. Baker Jr., Interactions of Certain Refractory Materials with Sodium, Report No: ANL-75-74, May 1976

J.K. Fink, J.J. Heiberger, R. Kumar, and R.A. Blomquist, Interactions of Refractories and Reactor Materials with Sodium, Nucl. Technol., 1977, 35, p 656–662

S.A. Meacham, The Compatibility of Refractory Materials with Boiling Sodium, Report No: CONF-760508, 1976

J. Jung, A. Reck, and R. Ziegler, The Compatibility of Alumina Ceramics with Liquid Sodium, J. Nucl. Mater., 1983, 119, p 339–350

S. Kano, E. Yoshida, Y. Hirakawa, Y. Tachi, H. Haneda, and T. Mitsuhashi, Sodium Compatibility of Ceramics; Liquid Metal Systems, H.U. Borgstedt and G. Frees, Ed., Plenum Press, New York, 1995, p 85–94

M. Alex, V. Balagi, K.R. Prasad, K.P. Sreekumar, and P.V. Ananthapadmanabhan, Plasma Sprayed Alumina Coatings for Radiation Detector Development, PRAMANA J. Phys., 2000, 55(56), p 927–932

A. Ravi Shankar, K. Thyagarajan, C.K. Upadhyay, C. Mallika, and U. Kamachi Mudali, Plasma Sprayed Alumina Coating on Inconel 600 for Neutron Detector Application, in Proceedings 6th Asian Thermal Spray Conference(ATSC 2014), 24–26 Nov 2014, Hyderabad, p 202–203

H.Y. Kim, J.H. Kim, K.S. Ha, J.H. Song, and J.H. Park, A Proposed Core Catcher System and Thermite Experimental Results, J. Energy Power Eng., 2011, 5, p 1005–1014

K.-H. Kanga, R.-J. Park, S.-B. Kim, K.Y. Suh, F.B. Cheung, and J.L. Rempe, Simulant Melt Experiments on Performance of the In-Vessel Core Catcher, Nucl. Eng. Des., 2007, 237, p 1803–1813

Powder Diffraction File-2 (PDF-2) JCPDS-ICDD, PCPDFWIN Version 2.02, May 1999.

A. Ravi Shankar, B.J. Babu, R. Sole, U.K. Mudali, and H.S. Khatak, Laser Remelting of Plasma Sprayed Zirconia Based Ceramic Coating for Pyrochemical Reprocessing Applications, Surf. Eng., 2007, 23, p 147–154

L. Duraes, B.F.O. Costa, R. Santos, A. Correia, J. Campos, and A. Portugal, Fe2O3/Aluminum Thermite Reaction Intermediate and Final Products Characterization, Mater. Sci. Eng. A, 2007, 465, p 199–210

W.H. Cook, Corrosion Resistance of Various Ceramics and Cermets to Liquid Metals, Report No: ORNL-2391, May 1960

Acknowledgments

The authors wish to thank Dr. Rajesh Ganenshan of Chemistry Group (IGCAR) and Dr. D. Ponraju of Fast Reactor Technology Group (IGCAR) for providing high purity liquid sodium and post-exposure cleaning of specimens. Special mentions to Mrs. B. Malarvizhi of Fast Reactor Technology Group (IGCAR) for providing instrumentation-related support to conduct uninterrupted experiment. We also thank Mr. R Suresh Kumar of Structural Mechanics Laboratory, Reactor Design Group (IGCAR), for providing round the clock man power for monitoring of experiment for whole duration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravi Shankar, A., Vetrivendan, E., Shukla, P.K. et al. Characterisation of Ceramic-Coated 316LN Stainless Steel Exposed to High-Temperature Thermite Melt and Molten Sodium. J. of Materi Eng and Perform 26, 5272–5283 (2017). https://doi.org/10.1007/s11665-017-2933-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2933-y