Abstract

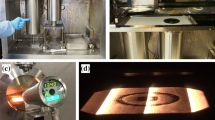

An Al-0.71 wt.% W alloy was prepared via powder metallurgy (PM) using a room-temperature pressing process and a subsequent hot-pressing process. Studies of the deformation behavior of the PM Al-W alloy were conducted using hot-compression tests in the temperature range from 420 to 570 °C and a strain rate range from 0.001 to 5 s−1. After the stress-strain data were acquired as a function of temperature and strain rate, processing maps that depict the variation in the power dissipation efficiency were constructed and interpreted via the dynamic materials model. The optimum temperature and strain rate combination for PM billet conditioning were demonstrated to be 560-570 °C and 0.001 s−1, respectively. Additionally, a secondary metal working process with a higher production efficiency on the PM billet was conducted at a higher strain rate from 0.01 to 0.1 s−1 and at a low temperature from 500 to 540 °C. The PM Al-W alloy was successfully extruded at 540 °C with a ram speed of 2 mm min−1 and an extrusion ratio of 5:1. The ultimate tensile strength and elongation of the test sample taken from the 15-mm-diameter as-extruded rods were 478 MPa and 15.4%, respectively.

Similar content being viewed by others

References

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Bendictus, and W.S. Miller, Recent Development in Aluminum Alloys for Aerospace Applications, Mater. Sci. Eng. A, 2000, 280, p 102–107

J.T. Wang, Y.K. Zhang, J.F. Chen, J.Y. Zhou, M.Z. Ge, Y.L. Lu, and X.L. Li, Effects of Laser Shock Peening on Stress Corrosion Behavior of 7075 Aluminum Alloy Laser Welded Joints, Mater. Sci. Eng. A, 2015, 647, p 7–14

S.D. Liu, C.B. Li, S.Q. Han, Y.L. Deng, and X.M. Zhang, Effect of Natural Aging on Quench-Induced Inhomogeneity of Microstructure and Hardness in High Strength 7055 Aluminum Alloy, J. Alloys Compd., 2015, 625, p 34–43

R.I. Rodriguez, J.B. Jordon, P.G. Allison, T. Rushing, and L. Garcia, Microstructure and Mechanical Properties of Dissimilar Friction Stir Welding of 6061-to-7050 Aluminum Alloys, Mater. Des., 2015, 83, p 63–65

E.M. Mazzer, C.R.M. Afonso, M. Galano, C.S. Kiminami, and C. Bolfarini, Microstructure Evolution and Mechanical Properties of Al-Zn-Mg-Cu Alloy Reprocessed by Spray-Forming and Heat Treated at Peak Aged Condition, J. Alloys Compd., 2013, 579(31), p 169–173

E.M. Mazzer, C.R.M. Afonso, C. Bolfarini, and C.S. Kiminami, Microstructure Study of Al 7050 Alloy Reprocessed by Spray Forming and Hot-Extrusion and Aged at 121 °C, Intermetallics, 2013, 43, p 182–187

H.Y. Li, W. Kang, and X.C. Lu, Effect of Age-Forming on Microstructure, Mechanical and Corrosion Properties of a Novel Al-Li Alloy, J. Alloys Compd., 2015, 640, p 210–218

Y.Y. Yang, S.Y. Zhong, Z. Chen, M.L. Wang, N.H. Ma, and H.W. Wang, Effect of Cr Content and Heat-Treatment on the High Temperature Strength of Eutectic Al-Si Alloys, J. Alloys Compd., 2015, 647, p 63–69

J.M. Wu, S.L. Zheng, J. Yuan, and Z.Z. Li, Mechanical Properties of Rapidly Solidified Al-Ti Alloys After Thermal Exposure, Trans. Nonferrous Met. Soc. China, 2000, 10(4), p 435–440

J.J. Cui, G.Y. Sun, J.R. Xu, Z.D. Xu, X.D. Huang, and G.Y. Li, A Study on the Critical Wall Thickness of the Inner Tube for Magnetic Pulse Welding of Tubular Al-Fe Parts, J. Mater. Proc. Technol., 2016, 227, p 138–146

A.H. Shah, M.B. Ahamed, D. Neena, F. Mohmed, and A. Lgbal, Investigations of Optical, Structural and Antibacterial Properties of Al-Cr Dual-Doped ZnO Nanostructures, J. Mater. Proc. Technol., 2014, 606, p 164–170

Z.B. He, D.X. Wei, X. Shen, Y. Chen, H.K. Ma, L.L. Wang, K. Du, Y. Yao, and R.H. Yu, Approximants of Al-Cr-Fe-Si Decagonal Quasicrystals Described by Single Structural Block, J. Alloys Compd., 2015, 647, p 797–801

D. OyolaLozano, Y. RojasMartÍnez, H. Bustos, and G.A. PérezAlcázar, Mössbauer and X-ray Study of Fe1−x Al x , 0.2 ≤ x≤0.5 Samples Produced by Mechanical Alloying, Hyperfine Interact., 2004, 156(1), p 569–574

M.H. Enayati and M. Salehi, Formation Mechanism of Fe3Al and FeAl Intermetallic Compounds During Mechanical Alloying, J. Mater. Sci., 2005, 40(15), p 3933–3938

D. Chen, Z. Chen, J.G. Cai, and Z.H. Chen, Preparation of W-Al Intermetallic Compound Powders by a Mechanochemical Approach, J. Alloys Compd., 2008, 461, p 23–25

S.G. Cai, X.F. Ma, H.G. Tang, W. Zhao, J.M. Yan, B. Zhao, and Z.H. Qiao, Preparation of W-Al-Mo Ternary Alloys by Mechanical Alloying, J. Alloys Compd., 2007, 430, p 77–80

M. Rafieia, S. Khademzadeha, and N. Parvinb, Characterization and Formation Mechanism of Nanocrystalline W-Al Alloy Prepared by Mechanical Alloying, J. Alloys Compd., 2010, 489, p 224–227

H.G. Tang, X.F. Ma, W. Zhao, X.W. Yan, and R.J. Hong, Preparation of W-Al Alloys by Mechanical Alloying, J. Alloys Compd., 2002, 347(1–2), p 228–230

Y.F. Ouyang, X.P. Zhong, and W.M. Wu, Extended Solid Solubility for Al-W Binary System by Mechanical Alloying, Sci. China A, 2000, 43(2), p 180–184

G.B. Schaffer, B.J. Hall, S.J. Boner, S.H. Huo, and T.B. Sercombe, The Effect of the Atmosphere and the Role of Pore Filling on the Sintering of Aluminum, Acta Mater., 2006, 54(1), p 131–138

L. Bolzoni, E. Herraiz, E.M. Ruiz-Navas, and E. Gordon, Study of the Properties of Low-Cost Powder Metallurgy Titanium Alloys by 430 Stainless Steel Addition, Mater. Des., 2014, 60, p 628–636

H.J. Li, L.H. Qi, H.M. Han, and L.J. Guo, Neural Network Modelling and Optimization of Semi-Solid Extrusion for Aluminium Matrix Composites, J. Mater. Proc. Technol., 2004, 151, p 126–132

J.H. Hwang, Finite Element Simulation and Experiment for Extrusion of Semi-Solid Al 2024, Int. J. Mach. Tool Manuf., 2000, 40, p 1311–1328

C. Nicolicescu, M. Ciobanu, and I. Stefan, Researches Regarding the Die Pressing Parameters on the Press Ability of Iron Powders, J. Optoelectron. Adv. Mater., 2011, 13(7–8), p 855–858

Y.V.R.K. Prasad and T. Sheshacharulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258

Y.V.R.K. Prasad, Processing Maps: A Status Report, J. Mater. Eng. Perform., 2003, 12(6), p 638–645

B.K. Prasad, Microstructural Alterations Through Heat Treatment and Its Influence on Wear Response of a Silicon Containing Zinc Based Alloy Under Different Test Conditions, Mater. Sci. Technol., 2003, 19(3), p 327–335

Y. Xue, Z.M. Zhang, G. Lu, Z.P. Xie, Y.B. Yang, and Y. Cui, Study on Flow Stress Model and processing Map of Homogenized Mg-Gd-Y-Zn-Zr Alloy During Thermo Mechanical Processes, J. Mater. Eng. Perform., 2015, 24(2), p 964–971

Y. Xue, L.H. Lang, G.L. Bu, and L. Li, Densification Modelling of Titanium Alloy Powder During Hot Isostatic Pressing, Sci. Sinter., 2011, 43(3), p 247–260

R.E.D. Mann, R.L. Hexemer, Jr., I.W. Donaldson, and D.P. Bishop, Hot Deformation of an Al-Cu-Mg Powder Metallurgy Alloy, Mater. Sci. Eng. A, 2011, 528, p 5476–5483

W.Y. Liu, H. Zhao, D. Li, Z.Q. Zhang, G.J. Huang, and Q. Liu, Hot Deformation Behaviour of AA7085 Aluminum Alloy During Isothermal Compression at Elevated Temperature, Mater. Sci. Eng. A, 2014, 596, p 176–182

N. Srinivasan, Y. Prasad, and P. Rama Rao, Hot Deformation Behavior of Mg-3Al Alloy-A Study Using Processing Map, Mater. Sci. Eng. A, 2008, 476, p 146–156

J.S. Jin, X.Y. Wang, H.E. Hu, and J.C. Xia, High-Temperature Deformation Behavior and Processing Map of 7050 ALUMINUM Alloy, Met. Mater. Int., 2012, 18(1), p 69–75

S. Venugopal, P. Venugopal, and S.L. Mannan, Optimisation of Cold and Warm Workability of Commercially Pure Titanium Using Dynamic Materials Model (DMM) Instability Maps, J. Mater. Proc. Technol., 2008, 202(1–3), p 201–215

S. Anbuselvan and S. Ramanathan, Hot Workability of as-Casted Extruded ZE41A Magnesium Alloy Using Processing Maps, Trans. Nonferrous Met. Soc. China, 2011, 21(2), p 257–264

R. Raj, Development of a Processing Map for Use in Warm-Forming and Hot-Forming Processes, Metall. Trans. A, 1981, 12, p 1089–1097

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, Y., Du, Y., Zhang, Z. et al. Processing Map of Powder Metallurgy Al-W Alloys at Elevated Temperatures. J. of Materi Eng and Perform 26, 3216–3225 (2017). https://doi.org/10.1007/s11665-017-2750-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2750-3