Abstract

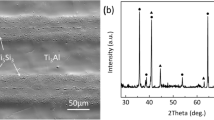

In order to characterize the interfacial behavior of brazed joints and offer theoretical basis for the applications of TiZrCuNi-based composite fillers, Cf/SiC composite and TC4 were brazed by TiZrCuNi filler, and the microstructures of joints versus temperature and versus holding time were systematically studied in this paper. The mechanical properties of brazed joints were measured and analyzed. The results showed that Ti(Zr)C, Ti5Si3, Ti2Cu, TiNi, TiZrCu2, Ti2(Cu,Ni) and Ti(s,s) were the predominant compounds in the joints. Brazing temperature had a distinct effect on the microstructures of joints: with the increase of brazing temperature, the structure of brazed joints was reduced from four parts to three parts, and the wavy reaction layer became continuous and much thicker. While holding time had a similar but weaker effect on microstructures: with the extension of holding time, the reaction layer became thicker, but it was difficult to induce the decrease in the structural parts of joint. The thickness of reaction layer determined the mechanical properties of joints. The results were beneficial for the selection of reinforced phases and the design of composite fillers to obtain better mechanical performances. When the brazing temperature was 940 °C and the holding time was 25 min, the maximum shear strength of brazed joints attained a value of 143.2 MPa.

Similar content being viewed by others

References

T. Ishikawa, S. Kajii, K. Matasanaga, and T. Hogani, A Tough, Thermally Conductive Silicon Carbide Composite with High Strength up to 1600 °C in Air, Science, 1998, 282, p 1295–1297

G. Boitier, J.L. Chermant, and J. Vicens, Multiscale Investigation of the Creep Behavior of a 2.5D Cf/SiC Composition, J. Mater. Sci., 1999, 34, p 2759–2767

R. Naslain, Design, Preparation and Properties of Non-oxide CMCs for Application in Engines and Nuclear Reactors: An Overview, Compos. Sci. Technol., 2004, 64, p 155–170

M. Singh and R. Asthana, Brazing of Advanced Ceramic Composites: Issues and Challenges, Ceram. Trans., 2007, 198, p 9–14

R. Asthana and M. Singh, Active Metal Brazing of Advanced Ceramic Composites to Metallic Systems, Advances in Brazing: Science, Technology and Applications, D.P. Sekulic, Ed., Woodhead Publishing Limited, Cambridge, 2013, p 323–360

W. Guo, L. Wang, Y. Zhu, and P.K. Chu, Microstructure and Mechanical Properties of C/C Composite/TC4 Joint with Inactive AgCu Filler Metal, Ceram. Int., 2015, 5, p 7021–7027

I.P. Semenova, G.I. Raab, E.R. Golubovskiy, and R.R. Valiev, Service Properties of Ultrafine-Grained Ti-6Al-4V Alloy at Elevated Temperature, J. Mater. Sci., 2013, 48, p 4806–4812

G.B. Lin, J.H. Huang, and H. Zhang, Joints of Carbon Fiber-Reinforced SiC Composites to Ti-Alloy Brazed by Ag-Cu-Ti Short Carbon Fibers, J. Mater. Process. Technol., 2007, 189, p 256–261

B. Chen, H.P. Xiong, X. Wu, Joining of Cf/SiC Composite with AuNi(Cu)-Cr Brazing Fillers and Interfacial Reactions, Weld. World, 2016, 60, p 813–819

Y.Z. Liu, L.X. Zhang, and C.B. Liu, Brazing C/SiC Composites and Nb with TiNiNb Active Filler Metal, Sci. Technol. Weld. Join., 2011, 16, p 193–198

J.H. Xiong, J.H. Huang, and Z.P. Wang, Joining of Cf/SiC Composite to Ti Alloy Using Composite Filler Materials, Mater. Sci. Technol. Lond., 2009, 25, p 1046–1050

B. Cui, J.H. Huang, and C. Cai, Microstructures and Mechanical Properties of Cf/SiC Composite and TC4 Alloy Joints Brazed with (Ti-Zr-Cu-Ni) + W Composite Filler Materials, Compos. Sci. Technol., 2014, 97, p 19–26

H. Zhang, Y. He, and F. Yang, Thermodynamic Assessment of Cu-Ni-Ti Ternary System Assisted with Key Measurements, Thermochim. Acta, 2013, 574, p 121–132

X.R. Song, H.J. Li, and V. Casalegno, Microstructure and Mechanical Properties of C/C Composite/Ti6Al4V Joints with a Cu/TiCuZrNi Composite Brazing Alloy, Ceram. Int., 2016, 5, p 6347–6354

G. Effenberg, SpringerMaterials, http://materials.springer.com/msi/docs/sm_msi_r_10_019042_01. Accessed 29 Apr 2016

N. Frage, L. Levin, E. Manor, R. Shneck, and J. Zabicky, Iron-Titanium-Carbon System. I. Equilibrium Between Titanium Carbide (TiC x ) of Various Stoichiometries and Iron-Carbon Alloys, Scripta Mater., 1996, 7, p 791–797

Acknowledgments

The research was supported by the National Natural Science Foundation of China (No. 51175037), People’s Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, D., Huang, J., Cui, B. et al. Interfacial Behavior and Its Effect on Mechanical Properties of Cf/SiC Composite/TiAl6V4 Joint Brazed with TiZrCuNi. J. of Materi Eng and Perform 26, 1114–1121 (2017). https://doi.org/10.1007/s11665-017-2571-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2571-4