Abstract

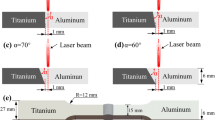

Disk laser weld brazing of dissimilar metals was carried out. Aluminum alloy 5083 and commercially pure titanium Grade 2 with the thickness of 2.0 mm were used as experimental materials. Butt weld brazed joints were produced under different welding parameters. The 5087 aluminum alloy filler wire with a diameter of 1.2 mm was used for joining dissimilar metals. The elimination of weld metal cracking was attained by offsetting the laser beam. When the offset was 0 mm, the intermixing of both metals was too high, thus producing higher amount of intermetallic compounds (IMCs). Higher amount of IMCs resulted in poorer mechanical properties of produced joints. Grain refinement in the fusion zone occurred especially due to the high cooling rates during laser beam joining. Reactions at the interface varied in the dependence of its location. Continuous thin IMC layer was observed directly at the titanium–weld metal interface. Microhardness of an IMC island in the weld metal reached up to 452.2 HV0.1. The XRD analysis confirmed the presence of tetragonal Al3Ti intermetallic compound. The highest tensile strength was recorded in the case when the laser beam offset of 300 μm from the joint centerline toward aluminum alloy was utilized.

Similar content being viewed by others

References

E. Spišák, Ľ. Kaščák, and J. Viňáš, Research into Properties of Joints of Combined Materials Made by Resistance Spot Welding, Chemické listy, 2011, 105, p 488–490

S.H. Chen, L.Q. Li, Y.B. Chen, and D.J. Liu, Si Diffusion Behavior during Laser Welding-Brazing of Al Alloy and Ti Alloy with Al-12Si Filler Wire, Trans. Nonferrous Metals Soc. China, 2010, 20, p 64–70

Y.H. Chen, Q. Ni, and L.M. Ke, Interface Characteristic of Friction Stir Welding Lap Joints of Ti/Al Dissimilar Alloys, Trans. Nonferrous Metals Soc. China, 2012, 22, p 299–304

M. Balasubramanian, Development of Processing Windows for Diffusion Bonding of Ti-6Al-4V Titanium Alloy and 304 Stainless Steel with Silver as Intermediate Layer, Trans. Nonferrous Metals Soc. China, 2015, 25, p 2932–2938

L. Kolařík, M. Kolaříková, and P. Vondrouš, Mechanical Properties of Interface of Heterogeneous Diffusion Welds of Titanium and Austenitic Steel, Key Eng. Mater., 2014, 586, p 178–181

H. Ozaki, S. Hayashi, and M. Kutsuna, Laser Roll Welding of Dissimilar Metal Joint of Titanium to Aluminium Alloy, Q. J. Jpn. Weld. Soc., 2008, 26, p 24–30

C. Zhang, J. Robson, O. Ciuca, and P. Prangnell, Microstructural Characterization and Mechanical Properties of High Power Ultrasonic Spot Welded Aluminium Alloy AA6111-TiAl64V Dissimilar Joints, Mater. Charact., 2014, 97, p 83–91

G. Liedl, A. Kratky, M. Mayr, and A. Saliger, Laser Assisted Joining of Dissimilar Materials, IQCMEA-ICF Processing, Performance and Failure Analysis of Engineering Materials, 14-17 Nov., 2011, Luxor, Egypt.

E. Anawa, A. Olabi, and F. Elshukri, Modeling and Optimization of Tensile Shear Strength of Titanium/Aluminium Dissimilar Welded Component, J. Phys. Conf. Ser., 2009, 181, p 1–10

A. Rao, G. Reddy, and S. Prasad, Microstructure and Tensile Properties of Dissimilar Metal Gas Tungsten Arc Welding of Aluminium to Titanium Alloy, Mater. Sci. Technol., 2011, 27, p 65–70

M. Kreimeier, F. Wagner, and F. Vollertsen, Laser Processing of Aluminium-Titanium-Tailored Blanks, Opt. Lasers Eng., 2005, 43, p 1021–1035

I. Szachogluchowicz, L. Sniezek, V. Hutsaylyuk, Low Cycle Fatigue Properties of AA2519–Ti6Al4 V Laminate Bonded by Explosion Welding, Engineering Failure Analysis, 2016, in press

D.M. Fronczek, J. Wojewoda-Budka, R. Chulist, A. Sypien, A. Korneva, Z. Szulc, N. Schell, and P. Zieba, Structural Properties of Ti/Al Clads Manufactured by Explosive Welding and Annealing, Mater. Des., 2016, 91, p 80–89

B. Li, Y. Shen, L. Luo, and W. Hu, Effects of Processing Variables and Heat Treatments on Al/Ti-6Al-4V Interface Microstructure of Bimetal Clad-Plate Fabricated via a Novel Route Employing Friction Stir Lap Welding, J. Alloys Compd., 2016, 658, p 904–913

W. Deqing, S. Ziyuan, and Q. Ruobin, Cladding of Stainless Steel on Aluminum and Carbon Steel by Interlayer Diffusion Bonding, Scr. Mater., 2007, 56, p 369–372

K. Nandagopal and C. Kailasanathan, Analysis of Mechanical Properties and Optimization of Gas Tungsten Arc Welding (GTAW) Parameters on Dissimilar Metal Titanium (6Al-4V) and Aluminium 7075 by Taguchi and ANOVA Techniques, J. Alloys Compd., 2016, 682, p 503–516

A. Wu, Z. Song, K. Nakata, J. Liao, and L. Zhou, Interface and Properties of the Friction Stir Welded Joints of Titanium Alloy Ti6Al4V with Aluminium Alloy 6061, Mater. Des., 2015, 71, p 85–92

K. Kalaiselvan, A. Elango, N. Nagarajan, and N. Mathiyazagan, Studies on Ti/Al Sheet Joint using Laser Beam Welding—A Review, Int. J. Chem. Nucl. Mater. Metall. Eng., 2014, 8, p 795–798

F. Caiazzo, V. Alfieri, F. Cardaropoli, G. Corrado, V. Sergi, Characterization of Disk-Laser Dissimilar Welding of Titanium Alloy Ti-6Al-4 V to Aluminium Alloy 2024, Proc. SPIE 8603, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications II, February 22, 2013

S. Chen, L. Li, Y. Chen, J. Dai, and J. Huang, Improving Interfacial Reaction Nonhomogeneity during Laser Welding—Brazing Aluminium to Titanium, Mater. Des., 2011, 32, p 4408–4416

K. Kalaiselvan and A. Elango, Mechanical Properties on Ti/Al Dissimilar Metal Butt Joint using Laser Beam Welding, J. Chem. Pharm. Sci., 2015, 6, p 65–68

J. Blackburn, C. Allen, P. Hilton, and L. Li, Nd:YAG Laser Welding of Titanium Alloys Using a Directed Gas Jet, J. Laser Appl., 2010, 22, p 71–78

I. Tomashchuk, P. Sallamand, E. Cicala, P. Peyre, and D. Grevey, Direct Keyhole Laser Welding of Aluminium Alloy AA5754 to Titanium Alloy Ti6Al4V, J. Mater. Process. Technol., 2015, 217, p 96–104

G. Casalino, M. Mortello, and P. Peyre, Yb-YAG Laser Offset Welding of AA5754 and T40 Butt Joint, J. Mater. Process. Technol., 2015, 223, p 139–149

S. Chen, L.Q. Li, Y. Chen, and J. Huang, Joining Mechanism of Ti/Al Dissimilar Alloys During Laser Welding-Brazing Process, J. Alloys Compd., 2011, 509(3), p 891–898

Sh Chen, L.Q. Li, and Y.B. Chen, Interfacial Reaction Mode and its Influence on Tensile Strength in Laser Joining Al Alloy to Ti Alloy, Mater. Sci. Technol., 2010, 26, p 230–235

Y. Chen, Sh Chen, and L. Li, Influence of Interfacial Reaction Layer Morphologies on Crack Initiation and Propagation in Ti/Al Joint by Laser Welding-Brazing, Mater. Des., 2010, 31, p 227–233

S. Chen, D. Yang, M. Li, Y. Zhang, J. Huang, J. Yang, and X. Zhao, Laser Penetration Welding of an Overlap Titanium-on-Aluminum Configuration, Int. J. Adv. Manuf. Technol., 2016, 87, p 1–11

F. Möller, M. Grden, C. Thomy, and F. Vollertsen, Combined Laser Beam Welding and Brazing Process for Aluminium Ti Hybrid Structures, Phys. Procedia, 2011, 12, p 215–223

J. Moravec, I. Nováková, and J. Bradáč, Effect of Age Hardening Conditions on Mechanical Properties of AW Alloy Welds, Manuf. Technol., 2016, 16(1), p 192–198

T. Kik, M. Slovacek, J. Moravec, and M. Vanek, Numerical Analysis of Residual Stresses and Distortions in Aluminium Alloy Welded Joints, Appl. Mech. Mater., 2015, 809–810, p 443–448

C.W. Tan, L.Q. Li, Y.B. Chen, A.M. Nasiri, and Y. Zhou, Microstructural Characteristics and Mechanical Properties of Fiber Laser Welded-Brazed Mg Alloy-Stainless Steel Joint, Weld. J., 2014, 98, p 399–409

W. Shouzheng, L. Yajiang, W. Juan, and L. Kun, Improving of Interfacial Microstructure of Ti/Al Joint during GTA Welding by Adopting Pulsed Current, Int. J. Adv. Manuf. Technol., 2014, 73, p 1307–1312

M. Gao, C. Chen, Y. Gu, and X. Zeng, Microstructure and Tensile Behavior of Laser Arc Hybrid Welded Dissimilar Al and Ti Alloys, Materials, 2014, 7, p 1590–1602

J.M. Sanchez-Amaya, T. Delgado, L. Gonzalez-Rovira, and F.J. Botana, Laser Welding of Aluminium Alloys 5083 and 6082 under Conduction Regime, Appl. Surf. Sci., 2009, 255, p 9512–9521

O.T. Ola and F.E. Doern, Keyhole-Induced Porosity in Laser-Arc Hybrid Welded Aluminum, Int. J. Adv. Manuf. Technol., 2015, 80, p 3–10

K. Labisz, L.A. Dobrzański, R. Maniara, and A. Olsen, Microstructure Evaluation of the Al-Ti Alloy with Magnesium Addition, J. Achiev. Mater. Manuf. Eng., 2011, 47, p 75–82

A. El Bataghy and M. Kutsuna, Laser Beam Welding of AA5052, AA5083 and AA6061 Aluminium Alloys, Adv. Mater. Sci. Eng., 2009, 2009, p 1–9

A. Chamanfar, T. Pasang, A. Ventura, and W.Z. Misiolek, Mechanical Properties and Microstructure of Laser Welded Ti-6Al-2Sn-4Zr-2Mo (Ti6242) Titanium Alloy, Mater. Sci. Eng. A, 2016, 663, p 213–224

R. Cao, T. Wang, C. Wang, Z. Feng, Q. Lin, and J.H. Chen, Cold Metal Transfer Welding-Brazing of Pure Titanium TA2 to Magnesium Alloy AZ31B, J. Alloys Compd., 2014, 605, p 12–20

L. Blacha, J. Mizera, and P. Folega, The Effects of Mass Transfer in the Liquid Phase on the Rate of Aluminum Evaporation from the Ti-6Al-7Nb Alloy, Metalurgija, 2014, 53, p 51–54

Acknowledgments

The paper was prepared under the support of VEGA Grant agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences, Projects No. 1/0876/15 and 1/1010/16. The authors would like also to thank financial assistance from the Slovak University of Technology Grant scheme for the support of excellent teams of young researchers, Project No. 1347. The publication is also the result of the project implementation: CE for development and application of advanced diagnostic methods in processing of metallic and nonmetallic materials—APRODIMET, ITMS:26220120048, supported by the Research & Development Operational Programme funded by the ERDF.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahul, M., Sahul, M., Vyskoč, M. et al. Disk Laser Weld Brazing of AW5083 Aluminum Alloy with Titanium Grade 2. J. of Materi Eng and Perform 26, 1346–1357 (2017). https://doi.org/10.1007/s11665-017-2529-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2529-6