Abstract

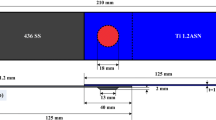

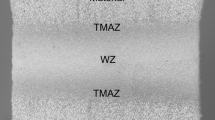

Microsample tensile testing was conducted to evaluate the quality of impact welds created by vaporizing foil actuator welding. Tensile test samples with a gauge length of 0.6 mm were electro-discharge machined out of welds created between 1-mm-thick aluminum alloy type 6061 (AA6061) sheets and 6-mm-thick copper (Cu110) plates. Aluminum sheets were used as flyers, while copper plates acted as targets. Flyer sheets in T6 as well as T4 temper conditions were utilized to create welds. Some of the welds made with T4 temper flyers were heat treated to a T6 temper. It was found that the welds made with T4 temper flyers were slightly stronger (max. of 270 MPa) than those produced with T6 temper flyers. Generally, failure propagated in a brittle manner across the weld interface; however, elemental mapping reveals material transfer on either member of the welded system. This work proves the feasibility to apply microsample tensile testing to assess impact welding, even when conducted with flyer sheets of 1 mm or less, and provides insight that is complementary to other test methods.

Similar content being viewed by others

References

R.A. Patterson, Fundamentals of Explosion Welding, ASM Handb., 1993, 6, p 160–164

Ramazan Kacar and Mustafa Acarer, An Investigation on the Explosive Cladding of 316L Stainless Steel-Din-P355GH Steel, J. Mater. Process. Technol., 2004, 152(1), p 91–96

V. Psyk, D. Risch, B.L. Kinsey, A.E. Tekkaya, and M. Kleiner, Electromagnetic Forming—A Review, J. Mater. Process. Technol., 2011, 211(5), p 787–829

A. Vivek, S.R. Hansen, B.C. Liu, and G.S. Daehn, Vaporizing Foil Actuator: A Tool for Collision Welding, J. Mater. Process. Technol., 2013, 213(12), p 2304–2311

J. Song, A. Kostka, M. Veehmayer, and D. Raabe, Hierarchial Microstructure of Explosive Joints: Example of Titanium to Steel Cladding, Mater. Sci. Eng. A, 2011, 528, p 2641–2647

S.D. Kore, P.P. Date, and S.V. Kulkarni, Efffect of Process Parameters on Electromagnetic Impact Welding of Aluminum Sheets, Int. J. Impact Eng., 2007, 34(8), p 1327–1341

A. Vivek, G. Daehn, J. Benzing, S. Hansen, and M. He, Impact Welding of Aluminum to Copper and Stainless Steel by Vaporizing Foil Actuator: Effect of Heat Treatment Cycles on Mechanical Properties and Microstructure, Metall. Mater. Trans. A, 2015, 46(10), p 4548–4558

D.M. Marsh, Micro-tensile Testing Machine, J. Sci. Instrum., 1961, 38(6), p 229

H. Sano, T. Shono, H. Sonoda, T. Takatsu, B. Ciucchi, R. Carvalho, and D. Pashley, Relationship Between Surface Area for Adhesion and Tensile Bond Strength-Evaluation of a Micro-tensile Bond Test, Dent. Mater., 1994, 10(4), p 236–240

P. Cardoso, R. Braga, and M. Carrilho, Evaluation of Micro-tensile, Shear and Tensile Tests Determining the Bond Strength of Three Adhesive Systems, Dent. Mater., 1998, 14(6), p 394–398

D.A. LaVan and W.N. Sharpe, Jr., Tensile Testing of Microsamples, Exp. Mech., 1999, 39(3), p 210–216

D. Heerens, G. Pinheiro, J.F. Santos, and N. Huber, On Characterisation of Local Stress-Strain Properties in Friction Stir Welded Aluminum AA 5083 Sheets Using Micro-tensile Specimen Testing and Instrumented Indentation Technique, Mater. Sci. Eng. A, 2010, 527(18), p 5018–5025

G.R. Cowan, O.R. Bergmann, and A.H. Holtzman, Mechanism of Bond Zone Wave Formation in Explosion-Clad Metals, Metall. Mater. Trans. B, 1971, 2(11), p 3145–3155

M. Zupan and K.J. Hemker, High Temperature Microsample Tensile Testing of γ-TiAl, Mater. Sci. Eng. A, 2001, 319–321, p 810–814

A. Vivek, B. Liu, D. Sakkinen, M. Harris, et al., Impact Welding of Aluminum Alloy 6061 to Dual Phase 780 Steel Using Vaporizing Foil Actuator. SAE technical paper 2015-01-0701, 2015. doi:10.4271/2015-01-0701

ASTM Standard B152/B152M-13, Standard Specification for Copper Sheet, Strip, Plate, Rolled Bar. ASTM International, West Conshohocken, PA, 2003. doi:9428-2959, www.astm.org

ASTM Standard B209-10, Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate. ASTM International, West Conshohocken, PA, 2003, 19428-2959, www.astm.org

Acknowledgments

The authors are grateful for sponsorship from the US Department of Energy’s Vehicle Technologies Program (Grant Number DE-EE006451). The views and opinions of authors expressed herein do not necessarily state or reflect those of the US Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benzing, J.T., He, M., Vivek, A. et al. A Microsample Tensile Test Application: Local Strength of Impact Welds Between Sheet Metals. J. of Materi Eng and Perform 26, 1229–1235 (2017). https://doi.org/10.1007/s11665-017-2514-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2514-0