Abstract

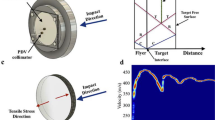

A novel porous honeycomb-type substrate has been developed using solid-state sintering stainless steel fibers. The porous sintered stainless steel fiber honeycombs (PSSSFH) are composed of a skeleton of sintered stainless steel fibers, three-dimensionally interconnected porous structures and multiple parallel microchannels. The bending behavior of the PSSSFH is investigated using three-point bending tests. Four stages, including an elastic stage, a yielding stage with a plateau, a hardening stage and a failure stage, are observed during the bending process of the PSSSFH. In the initial yielding stage, the bending forces increase slowly with displacement increasing, and then a yielding plateau follows, which is unique compared with other porous materials. Moreover, the structure parameters of the PSSSFH are varied to investigate the influence on the bending strength. It is determined that the multiple parallel microchannels can enhance the bending strength of porous stainless steel fiber sintered substrates (PSSFSS) and do not influence the variation trend of bending strength of PSSFSS with porosity increasing. The open ratio is conducive to increasing the bending strength, and the microchannel diameters ranging from 0.5 mm to 1.5 mm have little influence on the bending strength. In addition, both the increasing of sintering temperature and sintering time can strengthen the PSSSFH.

Similar content being viewed by others

References

B. Zhang and T.N. Chen, Calculation of Sound Absorption Characteristics of Porous Sintered Fiber Metal, Appl. Acoust., 2009, 70(2), p 337–346

J.C. Tan and T.W. Clyne, Ferrous Fibre Network Materials for Jet Noise Reduction in Aeroengines Part II: Thermo-Mechanical Stability, Adv. Eng. Mater., 2008, 10(3), p 201–209

E. Reichelt, M.P. Heddrich, M. Jahn, and A. Michaelis, Fiber Based Structured Materials for Catalytic Applications, Appl. Catal. A Gen., 2014, 476, p 78–90

P.Y. Yi, L.F. Peng, X.M. Lai, M.T. Li, and J. Ni, Investigation of Sintered Stainless Steel Fiber Felt as Gas Diffusion Layer in Proton Exchange Membrane Fuel Cells, Int. J. Hydrogen Energy, 2012, 37(15), p 11334–11344

Z.P. Xi, J.L. Zhu, H.P. Tang, Q.B. Ao, H. Zhao, J.Y. Wang, and C. Li, Progress of Application Researches of Porous Fiber Metals, Materials, 2011, 4(4), p 816–824

J. Banhart, Manufacture, Characterisation and Application of Cellular Metals and Metal Foams, Prog. Mater Sci., 2001, 46(6), p 559–632

V.N. Malheiro, J.N. Skepper, R.A. Brooks, and A.E. Markaki, In Vitro Osteoblast Response to Ferritic Stainless Steel Fiber Networks for Magneto-Active Layers on Implants, J. Biomed. Mater. Res. A, 2013, 101A(6), p 1588–1598

W. Zhou, Y. Tang, M.Q. Pan, X.L. Wei, and J.H. Xiang, Experimental Investigation on Uniaxial Tensile Properties of High-Porosity Metal Fiber Sintered Sheet, Mater. Sci. Eng. A, 2009, 525(1–2), p 133–137

W. Zhou, Y. Tang, B. Liu, R. Song, L.L. Jiang, K.S. Hui, K.N. Hui, and H.M. Yao, Compressive Properties of Porous Metal Fiber Sintered Sheet Produced by Solid-State Sintering Process, Mater. Des., 2012, 35, p 414–418

Z.W. Wan, B. Liu, W. Zhou, Y. Tang, K.S. Hui, and K.N. Hui, Experimental Study on Shear Properties of Porous Metal Fiber Sintered Sheet, Mater. Sci. Eng. A, 2012, 544, p 33–37

W. Zhou, Q.H. Wang, W.S. Ling, L.Z. He, Y. Tong, F. Wu, and J.L. Liao, Characterization of Three- and Four-Point Bending Properties of Porous Metal Fiber Sintered Sheet, Mater. Des., 2014, 56, p 522–527

P. Ducheyne, E. Aernoudt, and P.D. Meester, The Mechanical Behaviour of Porous Austenitic Stainless Steel Fibre Structures, J. Mater. Sci., 1978, 13(12), p 2650–2658

A.E. Markaki, V. Gergely, A. Cockburn, and T.W. Clyne, Production of a Highly Porous Material by Liquid Phase Sintering of Short Ferritic Stainless Steel Fibres and a Preliminary Study of Its Mechanical Behaviour, Compos. Sci. Technol., 2003, 63(16), p 2345–2351

T.W. Clyne, A.E. Markaki, and J.C. Tan, Mechanical and Magnetic Properties of Metal Fibre Networks, with and without a Polymeric Matrix, Compos. Sci. Technol., 2005, 65(15–16), p 2492–2499

J.C. Qiao, Z.P. Xi, H.P. Tang, J.Y. Wang, and J.L. Zhu, Influence of Porosity on Quasi-Static Compressive Properties of Porous Metal Media Fabricated by Stainless Steel Fibers, Mater. Des., 2009, 30(7), p 2737–2740

C.B. Fang, Z.P. Wan, B. Liu, and L.S. Lu, A Novel Sintered Stainless Steel Fiber Felt with Rough Surface Morphologies, Adv. Mater. Sci. Eng., 2014, 2014, p 1–7

P. Liu, Q.H. Zhao, G. He, Y.M. Qiao, H. Li, J.J. Zheng, J.P. Li, and Y.X. Zhang, Fabrication of Entangled Tough Titanium Wires Materials and Influence on Three-Dimensional Structure and Properties, J. Mater. Eng. Perform., 2014, 23(3), p 954–966

Y. Tang, W. Zhou, J.H. Xiang, W.Y. Liu, and M.Q. Pan, An Innovative Fabrication Process of Porous Metal Fiber Sintered Felts with Three-Dimensional Reticulated Structure, Mater. Manuf. Process., 2010, 25(7), p 565–571

F. Ribeiro, J.M. Silva, E. Silva, M.F. Vaz, and F.A.C. Oliveira, Catalytic Combustion of Toluene on Pt Zeolite Coated Cordierite Foams, Catal. Today, 2011, 176(1), p 93–96

L.L. Yan, B. Han, B. Yu, C.Q. Chen, Q.C. Zhang, and T.J. Lu, Three-Point Bending of Sandwich Beams with Aluminum Foam-Filled Corrugated Cores, Mater. Des., 2014, 60, p 510–519

S.K. Hyuna, H. Nakajima, L.V. Boykob, and V.I. Shapovalovc, Bending Properties of Porous Copper Fabricated by Unidirectional Solidification, Mater. Lett., 2004, 58(6), p 1082–1086

I.H. Oh, N. Nomura, N. Masahashi, and S. Hanada, Mechanical Properties of Porous Titanium Compacts Prepared by Powder Sintering, Scr. Mater., 2003, 49(12), p 1197–1202

Z. Lu, Z.H. Huang, S.S Jiang, W. Liu, and K.F. Zhang, Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding, Materials, 2016, 6(4), p 83(1–10)

N.Z. Wang, X. Chen, A. Li, Y.X. Li, H.W. Zhang, and Y. Liu, Three-Point Bending Performance of a New Aluminum Foam Composite Structure, Trans. Nonferrous Met. Soc. China, 2016, 26(2), p 359–368

D. Poquillon, V. Baco-Carles, Ph Tailhades, and E. Andrieu, Cold Compaction of Iron Powders-Relations between Powder Morphology and Mechanical Properties Part II. Bending Tests: Results and Analysis, Powder Technol., 2002, 126(1), p 75–84

Acknowledgments

This work was financially sponsored by the National Natural Science Foundation of China (No. 51375176), Guangdong Provincial Natural Science Foundation of China (No. 2014A030313264) and the fundamental research funds for the central universities, SCUT (No. 2013ZZ017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zou, S., Wan, Z., Lu, L. et al. Bending Behavior of Porous Sintered Stainless Steel Fiber Honeycombs. J. of Materi Eng and Perform 26, 744–751 (2017). https://doi.org/10.1007/s11665-016-2452-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2452-2