Abstract

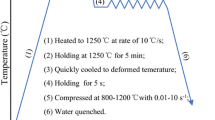

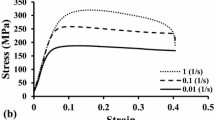

An integrated microstructure evolution model of thermomechanical processing was developed in terms of dynamic recrystallization (DRX), post-dynamic recrystallization (PDRX) and grain growth. Hot compression tests were carried out on a Gleeble-1500 thermal simulator under different conditions to model DRX, PDRX and short-time grain growth during the post-deformation and cooling process. Furthermore, in combination with the established microstructure evolution models, an elastic–plastic finite element model was built using DEFORM-2D software to simulate the microstructure evolution during the hot extrusion process. The simulation result was compared with the microstructure of a hot-extruded pipe of alloy G3 manufactured in a factory. The simulation results agree well with the experimental ones, validating the accuracy of the established microstructure evolution model. Furthermore, the finite element simulation is an effective method for hot deformation analysis, which can provide theoretical guidance for the optimization manufacturing parameters.

Similar content being viewed by others

References

L. Wang, F. Liu, J. Cheng, Q. Zuo, and C. Chen, Hot Deformation Characteristics and Processing Map Analysis for Nickel-Based Corrosion Resistant Alloy, J. Alloys Compd., 2015, 623, p 69–78

Z.F. Yin, M.L. Yan, Z.Q. Bai, W.Z. Zhao, and W.J. Zhou, Galvanic Corrosion Associated with SM 80SS Steel and Ni-Based Alloy G3 Couples in NaCl Solution, Electrochim. Acta, 2008, 53, p 6285–6292

B.S. Lee, M.C. Kim, J.H. Yoon, and J.H. Hong, Characterization of High Strength and High Toughness Ni–Mo–Cr Low Alloy Steels for Nuclear Application, Int. J. Press. Vessels Pip., 2010, 87, p 74–80

N. Park, I. Kim, Y. Na, and J. Yeom, Hot Forging of a Nickel-Base Superalloy, J. Mater. Process. Technol., 2001, 111, p 98–102

R. Doherty, D. Hughes, F. Humphreys, J. Jonas, D.J. Jensen, M. Kassner, W. King, T. McNelley, H. McQueen, and A. Rollett, Current Issues in Recrystallization: A Review, Mater. Sci. Eng. A, 1997, 238, p 219–274

G. Shen, S.L. Semiatin, and R. Shivpuri, Modeling Microstructural Development During the Forging of Waspaloy, Metall. Mater. Trans. A, 1995, 26, p 1795–1803

X. Li, L. Duan, J. Li, and X. Wu, Experimental Study and Numerical Simulation of Dynamic Recrystallization Behavior of a Micro-alloyed Plastic Mold Steel, Mater. Des., 2015, 66, p 309–320

Y. Lin and X.-M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

Y. Cao, H. Di, J. Zhang, J. Zhang, T. Ma, and R.D.K. Misra, An Electron Backscattered Diffraction Study on the Dynamic Recrystallization Behavior of a Nickel–Chromium Alloy (800H) During Hot Deformation, Mater. Sci. Eng. A, 2013, 585, p 71–85

Y. Cao, H. Di, R.D.K. Misra, X. Yi, J. Zhang, and T. Ma, On the Hot Deformation Behavior of AISI, 420 Stainless Steel Based on Constitutive Analysis and CSL Model, Mater. Sci. Eng. A, 2014, 593, p 111–119

J.T. Yeom, S.L. Chong, J.H. Kim, and N.K. Park, Finite-Element Analysis of Microstructure Evolution in the Cogging of an Alloy 718 Ingot, Mater. Sci. Eng. A, 2007, 449, p 722–726

Y.S. Na, J.T. Yeom, N.K. Park, and J.Y. Lee, Simulation of Microstructures for Alloy 718 Blade Forging Using 3D FEM Simulator, J. Mater. Process. Technol., 2003, 141, p 337–342

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson, Hot Deformation and Recrystallization of Austenitic Stainless Steel: Part II. Post-deformation Recrystallization, Metall. Mater. Trans. A, 2008, 39, p 1371–1381

C. Roucoules, P.D. Hodgson, S. Yue, and J.J. Jonas, Softening and Microstructural Change Following the Dynamic Recrystallization of Austenite, Metall. Mater. Trans. A, 1994, 25, p 389–400

Y. Lin, X.-Y. Wu, X.-M. Chen, J. Chen, D.-X. Wen, J.-L. Zhang, and L.-T. Li, EBSD Study of a Hot Deformed Nickel-Based Superalloy, J. Alloys Compd., 2015, 640, p 101–113

Z. Bi, M. Zhang, J. Dong, K. Luo, and J. Wang, A New Prediction Model of Steady State Stress Based on the Influence of the Chemical Composition for Nickel-Base Superalloys, Mater. Sci. Eng. A, 2010, 527, p 4373–4382

H. McQueen and N. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322, p 43–63

P. Peczak and M.J. Luton, The Effect of Nucleation Models on Dynamic Recrystallization II. Heterogeneous Stored-Energy Distribution, Philos. Mag. B, 1994, 70, p 817–849

A.D. Rollett and D. Raabe, A Hybrid Model for Mesoscopic Simulation of Recrystallization, Comput. Mater. Sci., 2001, 21, p 69–78

H. McQueen, Development of Dynamic Recrystallization Theory, Mater. Sci. Eng. A, 2004, 387, p 203–208

J. Wang, J. Dong, M. Zhang, and X. Xie, Hot Working Characteristics of Nickel-Base Superalloy 740H During Compression, Mater. Sci. Eng. A, 2013, 566, p 61–70

C.M. Sellars and W.M. Tegart, Relationship Between Strength and Structure in Deformation at Elevated Temperatures, Mem. Sci. Rev. Met., 1966, 63, p 731–746

M. El Wahabi, J.M. Cabrera, and J.M. Prado, Hot Working of Two AISI, 304 Steels: A Comparative Study, Mater. Sci. Eng. A, 2003, 343, p 116–125

M. Aghaie-Khafri and F. Adhami, Hot Deformation of 15-5 PH Stainless Steel, Mater. Sci. Eng. A, 2010, 527, p 1052–1057

Y. Wang, W. Shao, L. Zhen, and X. Zhang, Microstructure Evolution During Dynamic Recrystallization of Hot Deformed Superalloy 718, Mater. Sci. Eng. A, 2008, 486, p 321–332

D. Li, Q. Guo, S. Guo, H. Peng, and Z. Wu, The Microstructure Evolution and Nucleation Mechanisms of Dynamic Recrystallization in Hot-Deformed Inconel 625 Superalloy, Mater. Des., 2011, 32, p 696–705

X.-M. Chen, Y. Lin, D.-X. Wen, J.-L. Zhang, and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2014, 57, p 568–577

T. Senuma, and H. Yada, Microstructural Evolution of Plain Carbon Steels in Multiple Hot Working, Proceedings of the Riso International Symposium on Metallurgy and Materials Science, 7th ed., 1986, p 547–552

T. Sakai and J.J. Jonas, Dynamic Recrystallization: Mechanical and Microstructural Considerations, Acta Metall., 1984, 32, p 189–209

E.I. Poliak and J.J. Jonas, A One-Parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44, p 127–136

M.S. Chen, Y.C. Lin, and X.S. Ma, The Kinetics of Dynamic Recrystallization of 42CrMo Steel, Mater. Sci. Eng. A, 2012, 556, p 260–266

T. Sakai, Dynamic Recrystallization Microstructures Under Hot Working Conditions, J. Mater. Process. Technol., 1995, 53, p 349–361

C.M. Sellars, Modelling Microstructural Development During Hot Rolling, Mater. Sci. Technol., 1990, 6, p 1072–1081

T. Sakai, M. Ohashi, K. Chiba, and J.J. Jonas, Recovery and Recrystallization of Polycrystalline Nickel After Hot Working, Acta Metall., 1988, 36, p 1781–1790

L.X. Zhou and T.N. Baker, Effects on Dynamic and Metadynamic Recrystallization on Microstructures of Wrought IN-718 Due to Hot Deformation, Mater. Sci. Eng. A, 1995, 196, p 89–95

P. Uranga, A.I. Fernández, B. López, and J.M. Rodriguez-Ibabe, Transition Between Static and Metadynamic Recrystallization Kinetics in Coarse Nb Microalloyed Austenite, Mater. Sci. Eng. A, 2003, 345, p 319–327

M. Avrami, Kinetics of Phase Change. I, General Theory, J. Chem. Phys., 1939, 7, p 1103–1112

Y.C. Lin and M.S. Chen, Study of Microstructural Evolution During Metadynamic Recrystallization in a Low-Alloy Steel, Mater. Sci. Eng. A, 2009, 501, p 229–234

J.H. Beynon and C.M. Sellars, Modelling Microstructure and Its Effects During Multipass Hot Rolling, ISIJ Int., 1992, 32, p 359–367

W. Jue, Microstructure Controlled Extrudability Criterion of Nickel-Base Alloy Tubes, University of Science and Technology Beijing, Beijing, 2012

Acknowledgments

The authors appreciate the financial support from the National Basic Research Program (863 Program) of China under Grant No. 2013AA031005 and the National Natural Science Foundation of China under Grant No. 51301085.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, H., Dong, J., Zhang, M. et al. A Study on the Recrystallization Behavior of Ni-Based Alloy G3 During Hot Deformation. J. of Materi Eng and Perform 25, 5145–5156 (2016). https://doi.org/10.1007/s11665-016-2412-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2412-x