Abstract

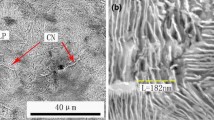

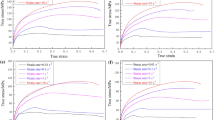

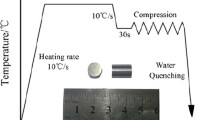

The compressive deformation behavior of 95CrMo steel, one of the worldwide used hollow steels, was investigated on a Gleeble-3500 thermo-simulation machine within temperature range of 1073-1323 K and strain rate range of 0.1-10 s−1. Considering the influence of work-hardening, dynamic recovery and dynamic recrystallization, a new constitutive model for high-temperature flow stress was established in this paper. The calculated values predicted by the new constitutive model lie fairly close to the experimental values with a correlation coefficient (R) of generally above 0.99 and an average absolute relative error of 3.00%, proving a good predictability of the new constitutive model. Also, a modified Sellars-Tegart-Garofalo model (STG model) was introduced to verify the precision of the new constitutive model. Compared to the modified STG model, the new constitutive model has a higher accuracy, which implies it is a reliable tool for predicting flow stress at high temperatures not only under equilibrium state, but also under transient deformation conditions. Besides, the new constitutive model was proved still viable in the initial stage of plastic deformation where plastic strain is lower than 0.05.

Similar content being viewed by others

References

F. Yin, L. Hua, H.J. Mao, and X.H. Han, Constitutive Modeling for Flow Behavior of GCr15 Steel Under Hot Compression Experiments, Mater. Des., 2013, 43, p 393–401

T. Yan, E.L. Yu, and Y.Q. Zhao, Constitutive Modeling for Flow Stress of 55SiMnMo Bainite Steel at Hot Working Conditions, Mater. Des., 2013, 50, p 574–580

K.P. Rao, Y.K.D.V. Prasad, and E.B. Hawbolt, Hot Deformation Studies on a Low-Carbon Steel: Part 2—An Algorithm for the Flow Stress Determination under Varying Process Conditions, J. Mater. Process. Technol., 1996, 56, p 908–917

H.J. McQueen, S. Yue, N.D. Ryan, and E. Fry, Hot Working Characteristics of Steels in Austenitic State, J. Mater. Process. Tech., 1995, 53, p 293–310

M.P. Phaniraj and A.K. Lahiri, The Applicability of Neural Network Model to Predict Flow Stress for Carbon Steels, J. Mater. Process. Technol., 2003, 141, p 219–227

E.S. Puchi-Cabrera, J.D. Guérin, M. Dubar, M.H. Staia, J. Lesage, and D. Chicot, Constitutive Description of Fe–Mn23–C0.6 Steel Deformed Under Hot-Working Conditions, Int. J. Mech. Sci., 2015, 99, p 143–153

E.I. Galindo-Nava and P.E.J. Rivera-Díaz-del-Castillo, Thermostatistical Modelling of Hot Deformation in FCC Metals, Int. J. Plast, 2013, 47, p 202–221

J.P. Sah, G. Richardson, and C.M. Sellars, Recrystallization During Hot Deformation of Nickel, J. Aust. Inst. Met., 1969, 14, p 292–297

Y.C. Lin, M.S. Chen, and J. Zhong, Prediction of 42CrMo Steel Flow Stress at High Temperature and Strain Rate, Mech. Res. Commun., 2008, 35, p 142–150

F.A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, Constitutive Analysis of Wrought Magnesium Alloy Mg–Al4–Zn1, Scripta Mater., 2007, 57, p 759–762

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42, p 470–477

W. Yu, L.X. Xu, Y. Zhang, and E.T. Dong, Constitutive Equation for High Temperature Flow Stress of 95CrMo Steel, Trans. Mater. Heat Treat., 2016, 10, p 261–267

E.S. Puchi-Cabrera, M.H. Staia, J.D. Guérin, J. Lesage, M. Dubar, and D. Chicot, Analysis of the Work-hardening Behavior of C-Mn Steels Deformed Under Hot-Working Conditions, Int. J. Plast, 2013, 51, p 145–160

D.L. Hong, T.H. Gu, and S.G. Xu, Drill Tool and Drill Steel, Metal. Industry Press, Beijing, 2000, p 121–134

Z.S. Wang, W. Yu, J.Z. Xiong, W.L. Tang, J.J. Yu, and J.Z. Zhang, Researches on Dynamic and Static Transformations of 95CrMo Drill Steel, J. Iron Steel Res., 2009, 159, p 22–25

N.Q. Peng, G.B. Tang, J. Yao, and Z.D. Liu, Hot Deformation Behavior of GCr15 Steel, J. Iron. Steel Res. Int., 2013, 20, p 50–56

J.G. Zhang, D.S. Sun, H.S. Shi, and H.B. Xu, Microstructure and Continuous Cooling Transformation Thermograms of Spray Formed GCr15 Steel, Mater. Sci. Eng., A, 2002, 326, p 20–25

H. Chen, Heat Treatment Process of the 95CrMo Conical Drill Rod, Mod. Mach., 2014, 01, p 75–78

Y.Q. Song, Z.P. Guan, P.K. Ma, and J.W. Song, Theoretical and Experimental Standardization of Strain Hardening Index in Tensile Deformation, Acta Mater. Sinica, 2006, 42, p 673–680

D. Samantaray, S. Mandal, C. Phaniraj, and A.K. Bhaduri, Flow Behavior and Microstructural Evolution During Hot Deformation of AISI, Type 316 L(N) Austenitic Stainless Steel, Mater. Des., 2011, 32, p 2797–2802

C. Zener and J.H. Hollomon, Problems in Non-Elastic Deformation of Metals, J. Appl. Phys., 1944, 15, p 22–27

S.A. Krishnan, C. Phaniraj, C. Ravishankar, A.K. Bhaduri, and P.V. Sivaprasad, Prediction of High Temperature Flow Stress in 9Cr–1Mo Ferritic Steel during Hot Compression, Int. J. Pres. Ves. Pip., 2011, 88, p 501–506

D.W. Suh, J.Y. Cho, O.K. Hwan, and H.C. Lee, Evaluation of Dislocation Density from the Flow Curves of Hot Deformed Austenite, ISIJ Int., 2002, 42, p 564–566

A. Yoshie, T. Fujita, M. Fujioka, K. Okamota, and H. Morikawa, Formulation of Flow Stress of Nb Added Steels by Considering Work-hardening and Dynamic Recovery, ISIJ Int., 1996, 36, p 467–473

F. Yin, L. Hua, H.J. Mao, X.H. Han, D.S. Qian, and R. Zhang, Microstructural Modeling and Simulation for GCr15 Steel during Elevated Temperature Deformation, Mater. Des., 2014, 55, p 560–573

C.X. Yue, L.W. Zhang, S.L. Liao, J.B. Pei, H.J. Gao, Y.W. Jia, and X.J. Lian, Research on the Dynamic Recrystallization Behavior of GCr15 Steel, Mater. Sci. Eng., A, 2014, 339, p 560–573

B.S. Xie, Q.W. Cai, W. Yu, J.M. Cao, and Y.F. Yang, Effect of Tempering Temperature on Resistance to Deformation Behavior for Low Carbon Bainitic YP960 Steels, Mater. Sci. Eng., A, 2014, 618, p 586–595

Acknowledgments

The authors would like to acknowledge the found supported by the National Science & Technology Pillar Program during the Twelfth Five-year Plan Period (Grant Nos. 2012BAE03B01). The authors would like to thank Mr. Yan-Jun Yin and Mrs. Jin Guo for their great help in Gleeble experiments.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xie, BS., Cai, QW., Wei, Y. et al. A New Constitutive Model for the High-Temperature Flow Behavior of 95CrMo Steel. J. of Materi Eng and Perform 25, 5127–5137 (2016). https://doi.org/10.1007/s11665-016-2388-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2388-6