Abstract

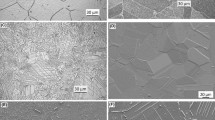

In this paper, microstructure and mechanical properties of 200 mm diameter Inconel 718 hemispherical domes processed at 1025 °C through closed die hammer forging have been investigated. Microstructure and mechanical properties of the forgings in radial and tangential directions were characterized using optical microscopy, scanning electron microscopy, impact testing, and tensile testing. Grain size of the forgings at three different locations was fine with an average grain size of ASTM No. 8-9. The typical tensile properties of the forgings in solution-treated and aged condition were ultimate tensile strength-1450 MPa, yield strength-1240 MPa, and ductility-25%. The fine grain size achieved in forgings has been attributed to delta phase present at grain boundaries which pinned the grains during forging and prevented grain coarsening.

Similar content being viewed by others

References

J. Benton, I. Bllinger, D.E.J. Jaekle, M.F. Osborn, Design and Manufacture of a Propellant Tank Assembly, AiAA, 2007, p 5559.

C. Clauss, AIAA 2007-5558 Design, Qualification, and Thermal Testing of a Specialized Composite Overwrap Pressure Vessel (COPV) Distribution A- Approved for Public Release, Distribution Unlimited AIAA-2007-5558 Distribution A- Approved for Public Release, Dist, 2007, p 1–10.

A.K. Jha, S.V.S.N. Murty, K. Sreekumar, and P.P. Sinha, High Strain Rate Deformation and Cracking of AA 2219 Aluminium Alloy Welded Propellant Tank, Eng. Fail. Anal., 2009, 16, p 2209–2216

J.G. Hust and A.F. Clark, A Survey of Compatibility of Materials with High Pressure Oxygen Service, Cryogenics (Guildf)., 1973, 13, p 325–336

A.F. Clark and J.G. Hust, A Review of the Compatibility of Structural Materials with Oxygen, AIAA J., 1974, 12, p 441–454

G. Shen, D. Kahlke, R. Denkenberger, and D. Furrer, Advances in the State-of-the-Art of Hammer Forged Alloy 718 Aerospace Components, Superalloys, 2001, 718, p 625–706

N.A. Wilkinson, Forging of 718-The Importance of TMP, Proc. Int. Symp. Superalloys, 1989, 718, p 119–133

S.C. Krishna, S.K. Singh, S.V.S.N. Murty, G. Venkata Narayana, A.K. Jha, B. Pant, and K.M. George, Closed Die Hammer Forging of Inconel 718, J. Metall., 2014, 2014, p 1–7. doi:10.1155/2014/972917

Z.J. Luo, H. Tang, F.C. Zeng, N.C. Guo, H.Y. Xu, H.B. Zhang, and L.F. Qi, An Effective Technique for Producing High Performance IN718 Forgings Using Hammers, J. Mater. Process. Tech., 1991, 28, p 383–390

M. Cheng, H.Y. Zhang, and S.H. Zhang, Microstructure Evolution of Delta-Processed IN718 During Holding Period After Hot Deformation, J. Mater. Sci., 2012, 47, p 251–256

R.C. Schwant, S.V. Thamboo, A.F. Anderson, C.B. Adasczik, B.J. Bond, L.A. Jackman, and J.F. Uginet, Large 718 Forgings for Land Based Turbines, Superalloys, 1997, 718(625), p 141–152

A.W. Dix, J.M. Hyzak, and R.P. Singh, Application of Ultra Fine Grain Alloy 718 Forging Billet, TMS, USA, 1992, p 23–32

G. Shen, R. Shivpuri, S.L. Semiatin, J.Y. Lee, and T. Altan, Investigation of Microstructure and Thermomechanical History in the Hammer Forging of an Incoloy 901 Disk, CIRP Ann. Manuf. Technol., 1993, 42, p 343–346

A. Chamanfar, L. Sarrat, M. Jahazi, M. Asadi, A. Weck, and A.K. Koul, Microstructural Characteristics of Forged and Heat Treated Inconel-718 Disks, Mater. Des., 2013, 52, p 791–800

J. Lacaze, M. Dehmas, A. Niang, and B. Viguier, TEM Study of High-Temperature Precipitation of Delta Phase in Inconel 718 Alloy, Adv. Mater. Sci. Eng., 2011, doi:10.1155/2011/940634

Y. Desvalles, M. Bouzidi, F. Boisand, and N. Beaude, Delta Phase in Inconel 718: Mechanical Properties and Forging Process Requirements, Superalloys (625 and Var. Deriv.), 1994, 718(706), p 281–291

M. Agilan, S.C. Krishna, S.K. Manwatkar, E.G. Vinayan, D. Sivakumar, and B. Pant, Effect of Welding Processes (GTAW & EBW) and Solutionizing Temperature on Microfissuring Tendency in Inconel 718 Welds, Mater. Sci. Forum, 2012, 710, p 603–607

S.-H. Zhang, H.-Y. Zhang, and M. Cheng, Tensile Deformation and Fracture Characteristics of Delta-Processed Inconel 718 Alloy at Elevated Temperature, Mater. Sci. Eng. A, 2011, 528, p 6253–6258

W. Horvath, W. Zechner, J. Tockner, M. Berchthaler, G. Weber, and E. Werner, The Effectiveness of Direct Aging on Inconel 718 Forgings Produced at High Strain Rates as Obtained on a Screw Press, Superalloys (625 and various derivatives), 2001, 718(706), p 223–228

H.S. Jeong, J.R. Cho, and H.C. Park, Microstructure Prediction of Nimonic 80A for Large Exhaust Valve During Hot Closed Die Forging, J. Mater. Process. Technol., 2005, 162–163, p 504–511

J.M. Zhang, Z.Y. Gao, J.Y. Zhuang, and Z.Y. Zhong, Modeling of Grain Size in Superalloy IN718 During Hot Deformation, J. Mater. Process. Technol., 1999, 88, p 244–250

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, and R. Srinivasan, Modeling Grain Size During Hot Deformation of IN 718, Scr. Mater., 1999, 42, p 17–23

H.Y. Zhang, S.H. Zhang, Z.X. Li, and M. Cheng, Hot Die Forging Process Optimization of Superalloy IN718 Turbine Disc Using Processing Map and Finite Element Method, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2010, 224, p 103–110

X. Zhao, R.P. Guest, S. Tin, D. Cole, J.W. Brooks, and M. Peers, Modelling Hot Deformation of Inconel 718 Using State Variables, Mater. Sci. Technol., 2004, 20, p 1414–1420

Y. Wang, W.Z. Shao, L. Zhen, and B.Y. Zhang, Hot Deformation Behavior of Delta-Processed Superalloy 718, Mater. Sci. Eng. A, 2011, 528, p 3218–3227

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, and R. Srinivasan, Microstructural Modeling of Metadynamic Recrystallization in Hot Working of IN 718 Superalloy, Mater. Sci. Eng. A, 2000, 293, p 198–207

D.J. Cha, D.K. Kim, J.R. Cho, and W.B. Bae, Hot Shape Forging of Gas Turbine Disk Using Microstructure Prediction and Finite Element Analysis, Int. J. Precis. Eng. Manuf., 2011, 12, p 331–336

Y. Zhu, Y. Zhimin, and X. Jiangpin, Microstructural Mapping in Closed Die Forging Process of Superalloy Nimonic 80a Valve Head, J. Alloys Compd., 2011, 509, p 6106–6112

W.-D. Cao and R.L. Kennedy, Application of Direct Aging To Allvac® 718PlusTM Alloy for Improved Performance, Superalloys (625, Deriv.), 2005, 718(706), p 213–222

M.G. Burke, W.J. Mills, R. Bajaj, and W. MiMin, Microstructure and Properties of Direct-Aged Alloy 625, Superalloys, 2001, 718, p 625–706

S.C. Krishna, N.K. Gangwar, A.K. Jha, B. Pant, and P.V. Venkitakrishnan, On the Direct Aging of Iron Based Superalloy Hot Rolled Plates, Mater. Sci. Eng. A, 2015, 648, p 274–279

L.A. Jackman, G.J. Smith, A.W. Dix, and M.L. Lasonde, Rotary Forge Processing of Direct Aged Inconel 718 for Aircraft Engine Shafts, Superalloys (625 Deriv.), 1991, 718(716), p 125–132

J.F. Radavich, J.W.H. Couts, Factors Affecting Delta Phase Precipitation and Growth at Hot Work Temperatures for Direct Aged INCO 718, TMS, Superalloys, 1984, p 497–507.

H.-T. Lee and W.-H. Hou, Fine Grains Forming Process, Mechanism of Fine Grain Formation and Properties of Superalloy 718, Mater. Trans., 2012, 53, p 716–723

L.C.M. Valle, L.S. Araújo, S.B. Gabriel, J. Dille, and L.H. De Almeida, The Effect of d Phase on the Mechanical Properties of an Inconel 718 Superalloy, J. Mater. Eng. Perform., 2013, 22, p 1512–1518

Y.H. Yang, J.J. Yu, X.F. Sun, T. Jin, H.R. Guan, and Z.Q. Hu, Investigation of Impact Toughness of a Ni-Based Superalloy at Elevated Temperature, Mater. Des., 2012, 36, p 699–704

P. Wang, S.P. Lu, N.M. Xiao, D.Z. Li, and Y.Y. Li, Effect of Delta Ferrite on Impact Properties of Low Carbon 13Cr–4Ni Martensitic Stainless Steel, Mater. Sci. Eng. A, 2010, 527, p 3210–3216

Acknowledgments

The authors would like to thank Dr. K. Sivan Director, Vikram Sarabhai Space Centre, Trivandrum, for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chenna Krishna, S., Rao, G.S., Singh, S.K. et al. Processing and Characterization of Sub-delta Solvus Forged Hemispherical Forgings of Inconel 718. J. of Materi Eng and Perform 25, 5477–5485 (2016). https://doi.org/10.1007/s11665-016-2377-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2377-9