Abstract

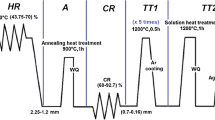

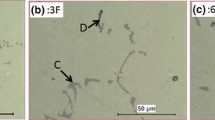

The effect of Fe contents (0.3-0.7 wt.%) on the microstructure, electrical conductivity, mechanical and creep properties of 8xxx aluminum conductor alloys was investigated. Results revealed that the as-cast microstructure of 8xxx alloys was consisted of equiaxed α-Al grains and secondary Fe-rich intermetallics distributed in the interdendritic region. The extruded microstructure showed partially recrystallized structure for 0.3% Fe alloy but only dynamically recovered structures for 0.5 and 0.7% Fe alloys. With increasing Fe contents, the ultimate tensile strength and yield strength were remarkably improved, while the electrical conductivity was slightly decreased. Moreover, the creep resistance was greatly improved, which is attributed to the larger volume fraction of fine intermetallic particles and smaller subgrain size in the higher Fe-containing alloys. The creep threshold stress was found to increase from 24.6 to 33.9 MPa with increasing Fe contents from 0.3 to 0.7%, respectively. The true stress exponent values were close to 3 for all three experimental alloys, indicating that the creep mechanism of 8xxx alloys was controlled by dislocation glide.

Similar content being viewed by others

References

M.Y. Murashkin, I. Sabirov, X. Sauvage, and R.Z. Valiev, Nanostructured Al and Cu Alloys with Superior Strength and Electrical Conductivity, J. Mater Sci., 2016, 51(1), p 33–49

W.H. Yuan and Z.Y. Liang, Effect of Zr Addition on Properties of Al-Mg-Si Aluminum Alloy Used for All Aluminum Alloy Conductor, Mater. Des., 2011, 32(8–9), p 4195–4200

L. Pan, B. Bourassa, and X.G. Chen, Effect of Thermomechanical Processing on Electrical and Mechanical Properties of Aluminum Conductor Alloys, Mater. Sci. Forum, 2014, 794–796, p 1121–1126

C. Olin, Aluminum Alloy Conductor, U.S.P. 3711339, US, 1973.

X.K. Ji, H. Zhang, S. Luo, F.L. Jiang, and D.F. Fu, Microstructures and Properties of Al-Mg-Si Alloy Overhead Conductor by Horizontal Continuous Casting and Continuous Extrusion Forming Process, Mater. Sci. Eng. A, 2016, 649, p 128–134

K.W. Barber and K.J. Callaghan, Improved Overhead Line Conductors Using Aluminum Alloy 1120, IEEE Trans. Power Deliv., 1995, 10(1), p 403–409

H.J. Mcqueen, E.H. Chia, and E.A. Starke, Fe-Particle-Stabilized Aluminum Conductors, JOM, 1986, 38(4), p 19–24

X.Y. Zhang, H. Zhang, X.X. Kong, and D.F. Fu, Microstructure and Properties of Al-0.70Fe-0.24Cu Alloy Conductor Prepared by Horizontal Continuous Casting and Subsequent Continuous Extrusion Forming, Trans. Nonferr. Met. Soc. China, 2015, 25(6), p 1763–1769

O.D. Sherby, A. Goldberg, and O.A. Ruano, Solute-diffusion-controlled dislocation creep in pure aluminium containing 0.026 at.% Fe, Philos. Mag., 2004, 84(23), p 2417–2434

P. Skjerpe, Intermetallic Phases Formed During DC-Casting of an Al-0.25 Wt Pct Fe-0.13 Wt Pct Si Alloy, Metall. Trans. A, 1987, 18(2), p 189–200

C.M. Allen, K.A.Q. O’Reilly, B. Cantor, and P.V. Evans, Intermetallic Phase Selection in 1XXX Al Alloys, Prog. Mater. Sci., 1998, 43(2), p 89–170

M. Shakiba, N. Parson, and X.G. Chen, Effect of Homogenization Treatment and Silicon Content on the Microstructure and Hot Workability of Dilute Al-Fe-Si Alloys, Mater. Sci. Eng. A, 2014, 619, p 180–189

D. Kalish, B.G. Lefevre, and S.K. Varma, Effect of Alloying and Processing on Subgrain-Strenth Relationship in Aluminum Conductor Alloys, Metall. Mater. Trans. A, 1977, 8(1), p 204–206

H.J. Mcqueen, K. Conrod, and G. Avramovic-cingara, The Hot-Working Characteristics of Eutectic-Rod-Stabilized Conductor Alloys, Can. Metall. Q., 1993, 32(4), p 375–386

M. Shakiba, N. Parson, and X.G. Chen, Effect of Iron and Silicon Content on the Hot Compressive Deformation Behavior of Dilute Al-Fe-Si Alloys, J. Mater. Eng. Perform., 2015, 24(1), p 404–415

R.W. Westerlund, Effects of Composition and Fabrication Practice on Resistance to Annealing and Creep of Aluminum Conductor Alloys, Metall. Trans., 1974, 5(3), p 667–672

D.E. Newbury, What is Causing Failures of Aluminum Wire Connections in Residential Circuits, Anal. Chem., 1982, 54(9), p A059–A064

E. Kandare, S. Feih, A. Kootsookos, Z. Mathys, B.Y. Lattimer, and A.P. Mouritz, Creep-Based Life Prediction Modelling of Aluminium in Fire, Mater. Sci. Eng. A, 2010, 527(4–5), p 1185–1193

F.J. Humphreys, Review—Grain and Subgrain Characterisation by Electron Backscatter Diffraction, J. Mater. Sci., 2001, 36(16), p 3833–3854

K. Liu, X. Cao, and X.-G. Chen, A New Iron-Rich Intermetallic-AlmFe Phase in Al-4.6Cu-0.5Fe Cast Alloy, Metall. Mater. Trans. A, 2012, 43(4), p 1097–1101

C.J. Shi, W.M. Mao, and X.G. Chen, Evolution of Activation Energy During Hot Deformation of AA7150 Aluminum Alloy, Mater. Sci. Eng. A, 2013, 571, p 83–91

E. Orowan, Dislocations and Mechanical Properties, Chap. 3, Dislocation in Metals, M. Cohen, Ed., AIME, New York, 1957, p 103–131

E. Arzt and D.S. Wilkinson, Threshold Stresses for Dislocation Climb Over Hard Particles—The Effect of an Attractive Interaction, Acta Metall., 1986, 34(10), p 1893–1898

E. Arzt and J. Rosler, The Kinetics of Dislocation Climb Over Hard Particles. 2. Effects of an Attractive Particle Dislocation Interaction, Acta Metall., 1988, 36(4), p 1053–1060

R.A. Karnesky, L. Meng, and D.C. Dunand, Strengthening Mechanisms in Aluminum Containing Coherent Al3Sc Precipitates and Incoherent Al2O3 Dispersoids, Acta Mater., 2007, 55(4), p 1299–1308

Y. Li and T.G. Langdon, An Examination of a Substructure-Invariant Model for the Creep of Metal Matrix Composites, Mater. Sci. Eng. A, 1999, 265(1–2), p 276–284

F. Dobes and P. Kratochvil, The Effect of Zr Addition on Creep of Fe-30 at.% Al Alloys, Intermetallics, 2013, 43, p 142–146

Z.G. Lin and F.A. Mohamed, Creep and Microstructure in Powder Metallurgy 15 vol.% SiCp-2009 Al Composite, J. Mater. Sci., 2012, 47(6), p 2975–2984

J.E. Dorn and N. Jaffe, Effect of Temperature on the Creep of Polycrystalline Aluminum by the Cross-slip Mechanism, Trans. Met. Soc. AIME, 1961, 221(2), p 229–233

N. Jaffe and J.E. Dorn, Effect of Stress on Creep Rate of High-Purity Aluminum in Cross-slip Region, Trans. Met. Soc. AIME, 1962, 224(6), p 1167–1173

O. Ryen, O. Nijs, E. Sjolander, B. Holmedal, H.E. Ekstrom, and E. Nes, Strengthening Mechanisms in Solid Solution Aluminum Alloys, Metall. Mater. Trans. A, 2006, 37A(6), p 1999–2006

P.K. Chaudhury and F.A. Mohamed, Creep and Ductility in an Al-Cu Solid-Solution Alloy, Metall. Mater. Trans. A, 1987, 18(12), p 2105–2114

V.K. Rao, D.M.R. Taplin, and P.R. Rao, The Grain Size Dependence of Flow and Fracture in a Cr-Mn-N Austenitic Steel from 300 to 1300 K, Metall. Trans. A, 1975, 6A(1), p 77–86

Acknowledgments

The authors would like to acknowledge financial support from Natural Science and Engineering Research Council of Canada (NSERC) and Rio Tinto through the NSERC Industrial Research Chair in Metallurgy of Aluminum Transformation at the University of Quebec at Chicoutimi.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, L., Liu, K., Breton, F. et al. Effect of Fe on Microstructure and Properties of 8xxx Aluminum Conductor Alloys. J. of Materi Eng and Perform 25, 5201–5208 (2016). https://doi.org/10.1007/s11665-016-2373-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2373-0