Abstract

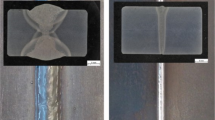

Vacuum electron beam welding (EBW) process was employed to butt weld 10-mm-thick HG785D high-strength steels. The penetration into the steel was adjusted by beam current. Microstructures at weld metal and heat-affected zone (HAZ) regions were comparatively observed. Mechanical properties of the EBWed joints including Vickers hardness, tensile and Charpy impact tests were evaluated. The results indicated that microstructures at the weld metal consisted of coarse lath martensite and a small amount of acicular martensite, while that in the HAZ was tempered sorbite and martensite. The grain size in the weld metal was found to be larger than that in the HAZ, and its proportion in weld metal was higher. The hardness in the weld metal was higher than the HAZ and base metal. The tensile strength and impact toughness in the HAZ was higher than that in the weld metal. All the behaviors were related to microstructure evolution caused by higher cooling rates and state of base metal. The fracture surfaces of tensile and impact tests on the optimized joint were characterized by uniform and ductile dimples. The results differed significantly from that obtained using arc welding process.

Similar content being viewed by others

References

Q. Zhang, J. Han, Z. Yang, and J. Wang, Properties of Heat Affected Zone for HG785D High Strength Steel, Trans. China Weld. I., 2014, 35, p 109–112 (In Chinese)

R. Zhong, F. Chen, C. Liu, and P. Zhang, Microstructure and Properties of Laser Welding and CO2 Welding of HG785 High Strength Structure Steel, Appl. Laser, 2011, 31(2), p 147–150 (In Chinese)

B. Zhang, X. Li, T. Wang, and X. Wang, Microstructure and Corrosion Behavior of Zr-702 Joined by Electron Beam Welding, Vacuum, 2015, 121, p 159–165

B.G. Zhang, J. Zhao, X.P. Li, and J.C. Feng, Electron Beam Welding of 304 Stainless Steel to QCr0.8 Copper Alloy with Copper Filler Wire, Trans. Nonferr Metal Soc, 2014, 24, p 4059–4066

S.Q. Wang, W.Y. Li, Y. Zhou, X. Li, and D.L. Chen, Tensile and Fatigue Behavior of Electron Beam Welded Dissimilar Joints of Ti–6Al–4 V and IMI834 Titanium Alloys, Mater. Sci. Eng., A, 2016, 649, p 146–152

X. Zhan, J. Chen, J. Liu, Y. Wei, J. Zhou, and Y. Meng, Microstructure and Magnesium Burning Loss Behavior of AA6061 Electron Beam Welding Joints, Mater. Des., 2016, doi:10.1016/j.matdes.2016.03.058

S. Wang and X. Wu, Investigation on the Microstructure and Mechanical Properties of Ti–6Al–4 V Alloy Joints with Electron Beam Welding, Mater. Des., 2012, 36, p 663–670

Y. Qi, J. Deng, Q. Hong, and L. Zeng, Electron Beam Welding, Laser Beam Welding and Gas Tungsten Arc Welding of Titanium Sheet, Mater. Sci. Eng., A, 2000, 280, p 177–181

T. Pasang, J.M.S. Amaya, Y. Tao, M.R. Amaya-Vazquez, F.J. Botana, J.C. Sabol et al., Comparison of Ti-5Al-5 V-5Mo-3Cr Welds Performed by Laser Beam, Electron Beam and Gas Tungsten Arc Welding, Procedia Eng., 2013, 63, p 397–404

C. Wiednig, C. Lochbichler, N. Enzinger, C. Beal, and C. Sommitsch, Dissimilar Electron Beam Welding of Nickel Base Alloy 625 and 9% Cr Steel, Procedia Eng., 2014, 86, p 184–194

J. Liu, X.L. Gao, L.J. Zhang, and J.X. Zhang, Effects of the Heterogeneity in the Electron Beam Welded Joint on Mechanical Properties of Ti6Al4 V Alloy, J. Mater. Eng. Perform., 2015, 24, p 315–328

A.K. Lakshminarayanan, V. Balasubramanian, and G. Madhusudhan Reddy, Microstructure and Mechanical Properties of Electron Beam-Welded AISI, 409 M-Grade Ferritic Stainless Steel, Int. J. Adv. Manuf. Technol., 2010, 55, p 153–162

G. Madhusudhana Reddy, C.V. Srinivasa Murthy, K. Srinivasa Rao, and K. Prasad Rao, Improvement of Mechanical Properties of Inconel 718 Electron Beam Welds—Influence of Welding Techniques and Postweld Heat Treatment, Int. J. Adv. Manuf. Technol, 2008, 43, p 671–680

B. Wu, J. Li, and Z. Tang, Study on the Electron Beam Welding Process of ZTC4 Titanium Alloy, Rare Metal Mat. Eng., 2014, 43, p 786–790

Y. Mei, Y. Liu, C. Liu, C. Li, L. Yu, Q. Guo et al., Effect of Base Metal and Welding Speed on Fusion Zone Microstructure and HAZ Hot-Cracking of Electron-Beam Welded Inconel 718, Mater. Des., 2016, 89, p 964–977

D. Du, R. Fu, Y. Li, L. Jing, J. Wang, Y. Ren et al., Modification of the Hall-Petch Equation for Friction-Stir-Processing Microstructures of High-Nitrogen Steel, Mater. Sci. Eng., A, 2015, 640, p 190–194

I. Brown, The Role of Microsegregation in Centreline Cold Cracking of High Strength Low Alloy Steel Weldments, Scripta Mater., 2006, 54, p 489–492

W. Xue, Q.G. Pan, Y.Y. Ren, W. Shang, H.Q. Zeng, and H. Liu, Microstructure and Type IV Cracking Behavior of HAZ in P92 Steel Weldment, Mater. Sci. Eng., A, 2012, 552, p 493–501

C. Du, J.P.M. Hoefnagels, R. Vaes, and M.G.D. Geers, Block and Sub-block Boundary Strengthening in Lath Martensite, Scripta Mater., 2016, 116, p 117–121

M.L. Zhu and F.Z. Xuan, Effect of microstructure on strain hardening and strength distributions along a Cr–Ni–Mo–V steel welded joint, Mater. Des., 2015, 65, p 707–715

M.L. Zhu, D.Q. Wang, and F.Z. Xuan, Effect of Long-term Aging on Microstructure and Local Behavior in the Heat-Affected Zone of a Ni–Cr–Mo–V Steel Welded Joint, Mater. Charact., 2014, 87, p 45–61

M.L. Zhu and F.Z. Xuan, Correlation Between Microstructure, Hardness and Strength in HAZ of Dissimilar Welds of Rotor Steels, Mater. Sci. Eng., A, 2010, 527, p 4035–4042

Acknowledgments

The research was financially supported by Postdoctoral Science Foundation of China (No. 2015M571406).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Q., Han, J., Tan, C. et al. Microstructures and Mechanical Properties of Weld Metal and Heat-Affected Zone of Electron Beam-Welded Joints of HG785D Steel. J. of Materi Eng and Perform 25, 5522–5529 (2016). https://doi.org/10.1007/s11665-016-2349-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2349-0