Abstract

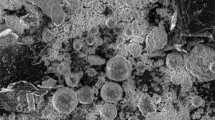

In order to improve the tribological properties of NiAl self-lubricating composites, V2O5 nanowires with average width of 39 nm were synthesized by hydrothermal method. Furthermore, NiAl self-lubricating composites containing V2O5 nanowires (NAV) were successfully fabricated using spark plasma sintering technique. The tribological characteristics and wear mechanisms of NAV were evaluated at different sliding speeds, counterface ball materials and elevated temperatures. The results revealed that the frictional properties of NAV improved slightly with adding V2O5 nanowires at room temperature if compared to NiAl self-lubricating composites without solid lubricant as investigated in previous studies, while the wear mechanisms of NAV change widely with the change of the counterface ball materials and sliding velocities. V2O5 nanowires showed a beneficial effect on tribological performance of NAV at high temperatures owing to the formation of the V2O5-enriched glaze film at temperatures above 700 °C, which acts as the lubricous and protective mask against the severe wear.

Similar content being viewed by others

References

R. Noebe, R. Bowman, and M. Nathal, Physical and Mechanical Properties of the B2 Compound NiAl, Int. Mater. Rev., 1993, 38(4), p 193–232

D. Miracle, Overview No. 104 the Physical and Mechanical Properties of NiAl, Acta Mater., 1993, 41(3), p 649–684

N. Stoloff, C. Liu, and S. Deevi, Emerging Applications of Intermetallics, Intermetallics, 2000, 8(9), p 1313–1320

K. Hahn and K. Vedula, Room Temperature Tensile Ductility in Polycrystalline B2 NiAl, Scripta Mater., 1989, 23(1), p 7–12

P. Nagpal and I. Baker, The Effect of Grain Size on the Room-Temperature Ductility of NiAl, Scripta Mater., 1990, 24(12), p 2381–2384

J.A. Hawk and D.E. Alman, Abrasive Wear of Intermetallic-Based Alloys and Composites, Mater. Sci. Eng. A, 1997, 239, p 899–906

I. Baker, P. Nagpal, F. Liu, and P. Munroe, The Effect of Grain Size on the Yield Strength of FeAl and NiAl, Acta Mater., 1991, 39(7), p 1637–1644

C. Yust and L. Allard, Wear Characteristics of an Alumina-Silicon Carbide Whisker Composite at Temperatures to 800 °C in Air, Tribol. Trans., 1989, 32(3), p 331–338

P.J. Blau and C.E. Devore, Sliding Behavior of Alumina/Nickel and Alumina/Nickel Aluminide Couples at Room and Elevated Temperature, J. Tribol., 1988, 110(4), p 646–652

P.J. Blau and C.E. Devore, Sliding Friction and Wear Behaviour of Several Nickel Aluminide Alloys Under Dry and Lubricated Conditions, Tribol. Inter., 1990, 23(4), p 226–234

A.M.M. Ibrahim, X.L. Shi, W.Z. Zhai, J. Yao, Z.S. Xu, L. Cheng et al., Tribological Behavior of NiAl-1.5 wt.% Graphene Composite Under Different Velocities, Tribol. Trans., 2014, 57(6), p 1044–1050

A.M.M. Ibrahim, X.L. Shi, A. Zhang, K. Yang, and W.Z. Zhai, Tribological Characteristics of NiAl Matrix Composites with 1.5 wt.% Graphene at Elevated Temperatures: An Experimental and Theoretical Study, Tribol. Trans., 2015, 58(6), p 1076–1083

Y.C. Xiao, X.L. Shi, W.Z. Zhai, K. Yang, and J. Yao, Effect of Temperature on Tribological Properties and Wear Mechanisms of NiAl Matrix Self-Lubricating Composites Containing Graphene Nanoplatelets, Tribol. Trans., 2015, 58(4), p 729–735

A.M.M. Ibrahim, X.L. Shi, W.Z. Zhai, and K. Yang, Improving the Tribological Properties of NiAl Matrix Composites Via Hybrid Lubricants of Silver and Graphene Nano Platelets, RSC Adv., 2015, 5(76), p 61554–61561

S. Zhu, Q. Bi, H. Wu, J. Yang, and W. Liu, NiAl Matrix High-Temperature Self-Lubricating Composite, Tribol. Lett., 2011, 41(3), p 535–540

T. Murakami, J. Ouyang, S. Sasaki, K. Umeda, and Y. Yoneyama, High-Temperature Tribological Properties of Al2O3, Ni-20 Mass.% Cr and NiAl Spark-Plasma-Sintered Composites Containing BaF2–CaF2 Phase, Wear, 2005, 259(1), p 626–633

O. Umanskyi, O. Poliarus, M. Ukrainets, and I. Martsenyuk, Effect of ZrB 2 , CrB 2 and TiB 2 Additives on the Tribological Characteristics of NiAl-Based Gas-Thermal Coatings, Trans Tech Publ, Key Eng. Mater., 2014, p 20–23

L. He, Y.F. Tan, X.L. Wang, Q.F. Jing, and X. Hong, Tribological Properties of Laser Cladding TiB2 Particles Reinforced Ni-Base Alloy Composite Coatings on Aluminum Alloy. Rare Met., 2015, 34(11), p 789–796

X.L. Shi, M. Wang, W.Z. Zhai, Z.S. Xu, Q.X. Zhang, and Y. Chen, Influence of Ti3SiC2 Content on Tribological Properties of NiAl Matrix Self-Lubricating Composites, Mater. Des., 2013, 45, p 179–189

X.L. Shi, S. Song, W.Z. Zhai, M. Wang, Z.S. Xu, J. Yao et al., Tribological Behavior of Ni3Al Matrix Self-Lubricating Composites Containing WS2, Ag and h-BN Tested from Room Temperature to 800 °C, Mater. Des., 2014, 55, p 75–84

X.L. Shi, W.Z. Zhai, M. Wang, Z.S. Xu, J. Yao, S. Song et al., Tribological Behaviors of NiAl Based Self-Lubricating Composites Containing Different Solid Lubricants at Elevated Temperatures, Wear, 2014, 310(1), p 1–11

X.L. Shi, M. Wang, W.Z. Zhai, Z.S. Zhu, Z.S. Xu, Q.X. Zhang et al., Friction and Wear Behavior of NiA-10 wt.% Ti3SiC2 Composites, Wear, 2013, 303(1), p 9–20

X.L. Shi, W.Z. Zhai, Z.S. Xu, M. Wang, J. Yao, S. Song et al., Synergetic Lubricating Effect of MoS2 and Ti3SiC2 on Tribological Properties of NiAl Matrix Self-Lubricating Composites Over a Wide Temperature Range, Mater. Des., 2014, 55, p 93–103

A. Pauschitz, M. Roy, and F. Franek, Mechanisms of Sliding Wear of Metals and Alloys at Elevated Temperatures, Tribol. Int., 2008, 41(7), p 584–602

H. Pasaribu, K. Reuver, D. Schipper, S. Ran, K. Wiratha, A. Winnubst et al., Environmental Effects on Friction and Wear of Dry Sliding Zirconia and Alumina Ceramics Doped with Copper Oxide, Int. J Refract. Met. Hard Mater., 2005, 23, p 386–390

M. Peterson, S. Murray, and J. Florek, Consideration of Lubricants for Temperatures Above 1000°F, ASLE Trans., 1959, 2(2), p 225–234

S. Zhu, Q. Bi, M. Niu, J. Yang, and W. Liu, Tribological Behavior of NiAl Matrix Composites with Addition of Oxides at High Temperatures, Wear, 2012, 274, p 423–434

R. Franz and C. Mitterer, Vanadium Containing Self-Adaptive Low-Friction Hard Coatings for High-Temperature Applications: A Review, Surf. Coat. Technol., 2013, 228, p 1–13

N. Fateh, G. Fontalvo, G. Gassner, and C. Mitterer, The Beneficial Effect of High-Temperature Oxidation on the Tribological Behaviour of V and VN Coatings, Tribol. Lett., 2007, 28(1), p 1–7

N. Fateh, G. Fontalvo, and C. Mitterer, Tribological Properties of Reactive Magnetron Sputtered V2O5 and VN–V2O5 Coatings, Tribol. Lett., 2008, 30(1), p 21–26

E. Lugscheider, S. Bärwulf, and C. Barimani, Properties of Tungsten and Vanadium Oxides Deposited by MSIP–PVD Process for Self-Lubricating Applications, Surf. Coat. Technol., 1999, 120, p 458–464

P. Mayrhofer, P.E. Hovsepian, C. Mitterer, and W.D. Münz, Calorimetric Evidence for Frictional Self-Adaptation of TiAlN/VN Superlattice Coatings, Surf. Coat. Technol., 2004, 177, p 341–347

A. Voevodin, C. Muratore, and S. Aouadi, Hard Coatings with High Temperature Adaptive Lubrication and Contact Thermal Management: Review, Surf. Coat. Technol., 2014, 257, p 247–265

R. Franz, J. Neidhardt, B. Sartory, R. Kaindl, R. Tessadri, P. Polcik et al., High-Temperature Low-Friction Properties Of Vanadium-Alloyed AlCrN Coatings, Tribol. Lett., 2006, 23(2), p 101–107

A.M. Cao, J.S. Hu, H.P. Liang, and L.J. Wan, Self-Assembled Vanadium Pentoxide (V2O5) Hollow Microspheres from Nanorods and their Application in Lithium-Ion Batteries, Angew. Chem. Int. Ed., 2005, 44, p 4391–4395

T. Zhai, H. Liu, H. Li, X. Fang, M. Liao, L. Li et al., Centimeter-Long V2O5 Nanowires: From Synthesis to Field-Emission, Electrochemical, Electrical Transport, Photoconductive Properties, Adv. Mater., 2010, 22, p 2547–2552

ASTM B962-08, Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle, ASTM International, West Conshohocken, PA, 2008

ASTM E92-82, Standard Test Method for Vickers Hardness of Metallic Materials, ASTM International, West Conshohocken, PA, 2003

ASTM G99-95, Standard Test Method for Wear Testing with a Pin on Disk Apparatus, ASTM International, West Conshohocken, PA, 1995

V. Merlin and N. Eustathopoulos, Wetting and Adhesion of Ni–Al Alloys on α-Al2O3 Single Crystals, J. Mater. Sci., 1995, 30(14), p 3619–3624

W. Zhang, J. Smith, and A. Evans, The Connection Between Ab Initio Calculations and Interface Adhesion Measurements on Metal/Oxide Systems: Ni/Al2O3 and Cu/Al2O3, Acta Mater., 2002, 50(15), p 3803–3816

X.L. Shi, W.Z. Zhai, M. Wang, Z.S. Xu, J. Yao, S.Y. Song, A.Q.U. Din, and Q.X. Zhang, Tribological Performance of Ni3Al-15 wt.% Ti3SiC2 Composites Against Al2O3, Si3N4 and WC-6Co from 25 to 800 °C, Wear, 2013, 303, p 244–254

Acknowledgments

This work was supported by the Project for Science and Technology Plan of Wuhan City (2013010501010139) and the Key Project for Science and Technology Plan of Henan province (152102210119). Authors also wish to gratefully thank the Material Research and Testing Center of Wuhan University of Technology for their assistance. Authors were grateful to M.J. Yang, S.L. Zhao and W.T. Zhu in Material Research and Test Center of WUT for their kind help with EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding author

Additional information

Yuchun Huang and Ahmed Mohamed Mahmoud Ibrahim have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Huang, Y., Ibrahim, A.M.M., Shi, X. et al. Tribological Characterization of NiAl Self-Lubricating Composites Containing V2O5 Nanowires. J. of Materi Eng and Perform 25, 4941–4951 (2016). https://doi.org/10.1007/s11665-016-2339-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2339-2